Choosing a 3d printer can feel overwhelming, but matching the machine’s features to your needs is the most important step. You want a 3d printer buying guide that helps you find the right fit for your projects and skills. Before you Choose an FDM 3D Printer, consider these key points:

- Think about your available space. Make sure the printer fits your home, office, or workshop.

- Review your budget and compare total costs, not just the sticker price.

- Define your application. FDM models work well for large prototypes and strong parts.

- Use a 3d printer buying guide to match your needs to the right printer.

This guide will help you make confident choices when choosing a 3d printer.

Key Takeaways

- Think about your space and money before you buy a 3D printer. Make sure the printer fits where you want to put it. Remember to count all costs, not just the first price.

- Know what you need for your project. Different printers are good at different jobs. Pick one that works for what you want to make, like prototypes or detailed models.

- Find easy-to-use features like auto bed leveling and simple filament loading. These features make printing easier, especially if you are new.

- Check the printer’s build volume and speed. A bigger build area lets you make larger things. Speed changes how fast you finish prints.

- Read reviews from other users to learn about the printer’s reliability and how well it works. Real feedback helps you stay away from printers with common problems.

Choose an FDM 3D Printer

Application Needs

When picking an fdm 3d printer, think about your project needs. Each 3d printer model is good at different things. The Elegoo Mars 4 Ultra is great for tiny, detailed prints. It works well for miniatures and prototypes. The Modix Big 60 V4 is best for big parts and strong models. It can make large items and is very reliable. If you want metal parts that last, try the Markforged Metal X. It is a cheaper way to make metal pieces. For schools, the FlashForge Adventurer 4 Pro is a safe and easy choice.

Tip: Always check the size of what you want to print. Bigger objects need a printer with a large build area. Small things can be made with a smaller machine.

You should look at the main things before picking an fdm 3d printer. The table below shows what to think about:

|

Criteria |

Description |

|---|---|

|

Required Part Aesthetics |

Pick a printer that gives you the look and colors you want. |

|

Nozzle Size |

Choose the nozzle size for more detail or faster prints. |

|

Ease of Operation and Maintenance |

Find printers with auto-calibration and easy filament loading. |

|

Environment |

Make sure there is good air flow and filters, especially in small rooms. |

|

Software Support |

Look for open-source software and regular updates. |

|

Safety |

Pick printers with built-in safety features. |

|

High Repeatability |

Good movement means your prints will look the same each time. |

|

Warranty |

A good warranty keeps your printer safe if it breaks. |

|

Active User Community |

Other users can help you fix problems and answer questions. |

Space Considerations

Check your space before getting an fdm 3d printer. Measure your home, office, or workshop. Some 3d printers are big and need strong tables. Others are small and fit on a desk. Always look at the printer’s build size and how much room it takes up. If you want to print big things, get a printer with a large build area. For small projects, a compact fdm printer saves space and keeps your area neat.

Note: Put your 3d printer in a place with good air flow. This helps lower emissions and keeps you safe.

FDM 3D Printer Basics

What Is FDM?

Fused deposition modeling is the most used 3d printing method today. Some people call it fused filament fabrication. This process melts plastic filament with a hot nozzle. The printer puts down the melted plastic in layers. It follows a digital plan to build your object from the bottom up. Fused deposition modeling is good for beginners and hobbyists. Small businesses also use it. You can make prototypes, tools, or custom parts with it.

Fused filament fabrication is popular because it is simple and cheap. Most schools and homes use this kind of 3d printer. In 2023, the global market for fused deposition modeling was $1.7 billion. Experts think it will grow to $6.9 billion by 2030. The yearly growth rate is 21.8%. This means fused filament fabrication is still a favorite for many people.

|

Metric |

Value |

|---|---|

|

Market Size (2023) |

USD 1.7 billion |

|

Projected Market Size (2030) |

USD 6.9 billion |

|

CAGR (2024-2030) |

21.8% |

Pros and Cons

Fused deposition modeling has many good points, but also some downsides. Here are some important things to know:

Pros:

- Fused filament fabrication costs less than other 3d printing types.

- There are many filament choices for your 3d printer.

- Most fused deposition modeling printers are simple to use and fix.

Cons:

- Fused deposition modeling does not have as high resolution as other methods.

- Most prints will show lines between layers.

- Fused filament fabrication cannot make tiny details like SLA or SLS printers.

|

Technology |

Layer Resolution |

Surface Finish |

Accuracy |

|---|---|---|---|

|

SLA |

as fine as 25 microns |

Smooth, high detail |

High |

|

FDM |

0.1–0.3 mm |

Visible layer lines |

Lower |

|

SLS |

Not as fine as SLA |

Strong, durable |

Moderate |

Note: SLA printers can print layers as thin as 0.05 mm. Fused deposition modeling usually uses thicker layers, about 0.1–0.3 mm. SLA gives you smoother and more accurate prints than fused filament fabrication.

Pick fused deposition modeling if you want something easy, flexible, and not too expensive. If you need the best detail and accuracy, try a different 3d printing method.

Printing Goals

Project Types

Before you select a 3d printer, you should think about the kinds of projects you want to create. FDM 3d printers work well for many uses. You can make quick prototypes, basic parts, and models. Many people choose this type of printer because it is affordable and easy to set up. The 3d printer builds objects by melting plastic filament and laying it down in layers. This process helps you turn your ideas into real objects fast.

Tip: Write down your main project goals. If you plan to make simple models or test ideas, an FDM 3d printer is a strong choice.

Here are some common project types you can complete with an FDM 3d printer:

- Quick prototypes for testing ideas

- Basic parts for repairs or hobbies

- Models for school, work, or fun

If you know your project type, you can pick a printer that matches your needs.

Frequency

How often you use your 3d printer matters. If you print every day or run long jobs, your printer will face more wear and tear. Frequent and intense use can shorten the lifespan of your 3d printer. High-volume printing means you need to check and maintain your printer more often. You should clean moving parts and replace worn pieces to keep your 3d printer working well.

Note: If you plan to print often, choose a printer known for durability and easy maintenance.

Think about your printing habits. If you print only a few times a month, a basic model may work. If you print every week or run large projects, look for a 3d printer built for heavy use.

Printer Features

Print Quality

You want your 3d printer to make good prints. Print quality depends on a few things. These include resolution, nozzle size, and how steady the printer is. Resolution shows how thin each layer is. If the resolution is low, layers are thick and lines show more. High resolution means smoother surfaces and better details. Most FDM printers have a resolution from 0.1 mm to 0.3 mm. This is good for strong parts but not as detailed as resin printers.

|

FDM Printing |

Resin Printing |

|

|---|---|---|

|

Print Quality |

Lower detail, good for strong parts |

More detail and smooth, good for tiny models |

|

Material Properties |

More types of strong materials |

Special materials for certain uses |

|

Build Size |

Usually bigger build space |

Smaller build space |

|

Speed and Efficiency |

Faster for big, simple things |

Better for small, detailed things |

|

Post-Processing |

Needs support removal and smoothing |

Needs lots of washing and curing |

Check the printer’s resolution before you buy it. Some printers let you change the resolution for each print. This helps you pick between speed and quality. If you want high detail for small things, get a printer with a small nozzle and a strong frame. For bigger, simple parts, normal resolution is fine.

Tip: Slower print speed and careful setup make prints look better. Try different settings to see what works best for you.

Build Volume

Build volume is the biggest size you can print. You measure it by width, depth, and height. A bigger build volume lets you make large models or many small ones at once. Most home 3d printers have a build volume from 200 x 200 x 200 mm to 300 x 300 x 400 mm. Bigger printers for factories can print even larger things.

Pick a build volume that fits your usual projects. If you make small things, a small printer saves space and power. For big parts or printing many things at once, get a printer with a bigger build area. Remember, bigger printers need more room and stronger tables.

Speed

Speed is important when you print. Print speed is how fast the nozzle moves and puts down plastic. Most 3d printers print at 50–60 mm/s for medium quality. If you print faster, you finish sooner but might lose detail.

- Slow speeds give better detail and smoother prints.

- Fast speeds can cause problems like rough layers or weak spots.

- High speed saves time but can make prints look worse.

Change the print speed for each project. For detailed models, go slow for better results. For big, simple parts, faster speed is okay if you do not mind less detail.

|

Cartesian Printers |

Delta Printers |

|

|---|---|---|

|

Print Quality |

Great print quality and even heat |

Harder to get perfect prints |

|

Speed |

Usually slower than delta printers |

Known for being fast |

|

Reliability |

Good for people who want steady results |

Not as popular because they are tricky to set up |

Cartesian printers have a box shape and are easy to use. They make good prints and work well. Delta printers are faster and good for tall prints. But they are harder to set up and may not print as neatly as Cartesian printers.

Material Compatibility

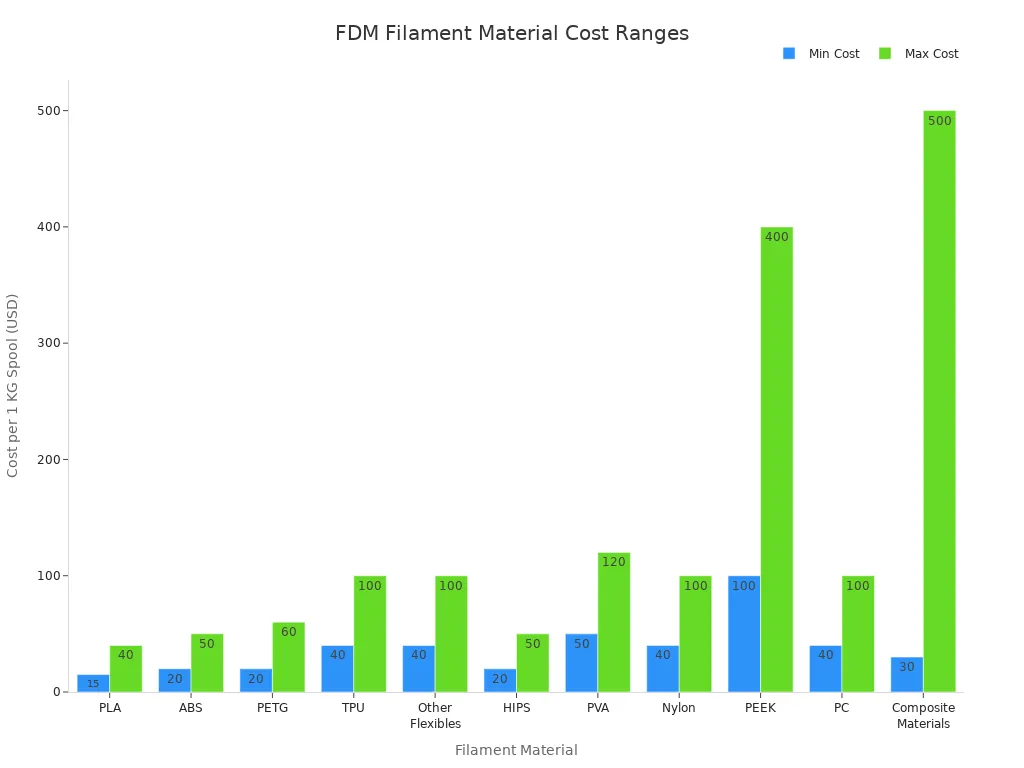

Material compatibility means what kinds of filament you can use. Most FDM printers work with many types of filament. Each material has its own price, strength, and print rules. Check what filaments your printer can use before buying.

|

Filament Material |

Cost Range (per 1 KG spool) |

|---|---|

|

PLA |

$15 – $40 |

|

ABS |

$20 – $50 |

|

PETG |

$20 – $60 |

|

TPU |

$40 – $100 |

|

Other Flexibles |

$40 – $100 |

|

HIPS |

$20 – $50 |

|

PVA |

$50 – $120 |

|

Nylon |

$40 – $100 |

|

PEEK |

$100 – $400 |

|

PC |

$40 – $100 |

|

Composite Materials |

$30 – $500 |

PLA and ABS are the most used and cheapest. Special filaments like PEEK and composites cost more but are stronger or bendy. The price of filament matters if you print a lot. Plan for these costs when picking your printer.

Ease of Use

Ease of use is important, especially if you are new. Look for features that make printing simple. Many new printers have touchscreens, easy menus, and helpful alerts.

- A screen with easy buttons helps you change settings and watch your print.

- Filament run-out detection stops the print if you run out of filament, so you do not waste time or material.

- Power-off recovery lets you keep printing after a power cut, so you do not lose your work.

These features make printing easier and help you avoid mistakes. Also, look for auto bed leveling, easy filament loading, and good help from the company. These things make your first prints better and help you learn faster.

Note: A 3d printer that is easy to use and has smart features lets you be creative instead of fixing problems.

3D Printer Comparison

Reliability

You want a 3d printer that works every time you use it. Reliability means the machine prints well without many errors. Look for a printer with a strong frame and high-quality parts. Good durability helps your 3d printer last longer. Printers with metal frames and sturdy motors often have better durability. You should also check if the printer has a good cooling system. This keeps the machine from overheating and helps with durability. Some brands offer longer warranties, which shows they trust the durability of their 3d printer.

Tip: Read about how often users need to fix or replace parts. A reliable 3d printer saves you time and money.

Cost

You need to think about the cost before you buy a 3d printer. The price can change a lot based on the type and features. Here is a simple table to help you see the price range for different categories:

|

Category |

Price Range |

|---|---|

|

Entry-level |

Under €300 |

|

Mid-range |

Under €500 |

|

Professional |

Under €1000 |

The total cost of operation includes more than just the price of the printer. You also pay for filament, spare parts, and electricity. Some printers use more power or need expensive filaments. You should add these costs to your budget. A low-cost printer may seem like a good deal, but if it breaks often, you will spend more on repairs. Always check the durability and the total cost before you decide.

User Reviews

User reviews give you real feedback about each 3d printer. You can learn about common problems, print quality, and durability from other users. Look for reviews that talk about long-term use. Some users share tips on how to get the best results from their printer. If many people say a printer has good durability and low cost, it is a strong choice. You should also check if users find the printer easy to set up and use. Reviews help you avoid 3d printers with hidden problems.

Note: Always read both good and bad reviews. This gives you a full picture of the 3d printer’s strengths and weaknesses.

Extra Features

Modern 3d printers offer extra features that make your printing experience smoother and safer. These upgrades help you get better results and protect you while you work. When you choose a 3d printer, look for these important extras.

Auto Bed Leveling

Auto bed leveling takes the guesswork out of setting up your 3d printer. You do not need to adjust the bed by hand. The SV08 Max, for example, uses an Eddy Current Scanning system. This technology levels a large 500×500 mm bed in just 80 seconds. It works without touching the surface and can spot even tiny changes. You get these benefits:

- The nozzle always stays at the right distance from the bed.

- Your first layer sticks better, which means fewer failed prints.

- Print quality improves, and you spend less time on setup.

Tip: Auto bed leveling helps you get great results, even if you are new to 3d printing.

Connectivity

You have several ways to connect to your 3d printer. Each method has its own strengths. The table below shows the most common options and what you can expect from each one.

|

Connectivity Method |

Description |

|---|---|

|

SD Card |

You can print by inserting an SD card with G-code files. Sometimes, loose contacts or wrong file formats cause problems. |

|

Wi-Fi |

Many users like Wi-Fi for remote printing. You can control your printer from another room. Always watch for clogs or fire risks. |

|

OctoPrint |

This open-source tool lets you control your 3d printer and use advanced features. You need extra hardware to set it up. |

Choose the connection that fits your workflow. Wi-Fi gives you freedom, while SD cards keep things simple.

Safety

Safety matters when you use a 3d printer. You face risks like hot surfaces, moving parts, and fumes. Modern 3d printers include features to keep you safe:

- Good ventilation reduces exposure to ultrafine particles and fumes.

- Shields and covers protect you from burns and moving parts.

- Risk management plans and safety gear lower the chance of injury.

Beginner and User Recommendations

Beginner

If you are new to 3d printing, pick a printer that is simple and works well. Look for things like auto bed leveling and easy buttons. Quick setup helps you start fast and not get stuck. These features make learning easier and less stressful. Many printers let you use WiFi or Bluetooth. You can start prints from your computer or phone. A strong frame keeps the printer steady. Quiet machines are better for home or school.

Here are some good 3d printers for beginners:

- Bambu Lab A1 Mini: Has auto bed leveling, WiFi/Bluetooth, good for small models.

- Prusa Core ONE: Has a closed chamber, prints fast, easy software, big support group.

- QIDI Q1 Pro: Auto-levels, keeps heat inside, uses many materials.

- Creality Ender 3 V3 SE: Low price, big print space, simple to put together.

- ModelMaker 2.0: Easy buttons, quiet, strong build, great for learning.

- FlashForge Creator Pro 2: Two extruders, closed chamber, easy to load filament.

- Anycubic Kobra 3 Combo: Helps level the bed, has a touchscreen, sets up fast.

- Bambu Lab P1S: Bigger print area, prints fast, auto-levels.

- BambuLabs X1C: Smart auto-leveling, AI checks prints, very precise.

Tip: Pick a printer with lots of users. You will find more help and guides when you need it.

Hobbyist

If you print for fun, you might want more features and choices. You may want to print bigger things or try new filaments. Choose a printer with a larger print area and steady results. Some hobbyists like open-source printers for custom projects.

|

Feature |

Description |

|---|---|

|

Bigger print space lets you make more types of things. |

|

|

Reliability |

Fewer problems mean you spend more time printing. |

|

Customizability |

Open-source printers let you change parts and software. |

|

Leveling features |

Auto-leveling and mesh bed maps make setup simple. |

|

Quality of Life |

Touchscreens and filament sensors make printing easier. |

|

Special Features |

Covers and smart software help with special projects. |

Small Business

If you have a small business, you need a printer that works well every day. Pick one with a strong frame and fast printing. It should use many types of filament. Auto bed leveling and a heated chamber help stop mistakes. Get a printer with a warranty and good support. This keeps your business running without long stops.

Think about all costs, like filament and fixing the printer. A good printer saves money over time. Pick a model that fits your work now and can handle more jobs as your business grows.

Decision Checklist

Final Steps

Before you pick your 3d printer, use a simple checklist. The table below shows the most important things to think about when choosing:

|

Criterion Number |

Criterion Name |

Description Summary |

|---|---|---|

|

1 |

Application |

Decide what you want to make, like models or tools. |

|

2 |

Accuracy & Surface Finish |

Pick how smooth and exact you want your prints. |

|

3 |

Build Size |

Get a printer that can make almost all your parts. |

|

4 |

Material |

Think about what materials you need and their costs. |

|

5 |

Color Capability |

Choose if you want your printer to use colors. |

|

6 |

Build Speed |

See how fast the printer works and if it fits your needs. |

|

7 |

Maintenance |

Learn how much care and time the printer needs. |

|

8 |

Post-processing |

Check if you need extra steps, space, or tools after printing. |

|

9 |

Initial Investment |

Look at the price, setup, training, and warranty. |

|

10 |

Recurring Costs |

Add up costs for supplies, repairs, and work over time. |

Follow these steps to help you choose well:

- Write down what you need. Think about what you want to make, how smooth you want your prints, and what materials you like.

- Look up different types of printers. Compare FFF, SLA, and SLS to see which one matches your plans.

- Check the main features. Look at how big it can print, how thin the layers are, and other details.

- Compare different printers. Use guides and what other people say to see which is best.

- Look at how often the printer works and how fast it finishes jobs.

- See what is new in the market and how printers are getting better.

- Use this checklist to make sure you do not miss anything important.

- Read what other users say. Learn from their good and bad experiences.

- Pick the printer that fits your needs and your budget.

You can choose the right FDM 3d printer by matching its features to your needs. Focus on what matters most for your projects. Recent buyer surveys highlight these top factors:

- Filament compatibility lets you use more materials.

- Dual extruder options help with advanced prints.

- Budget planning covers all costs.

- Regular maintenance keeps your printer working well.

- Check uptime and print speed for better results.

A simple checklist helps you avoid mistakes and compare options. It guides you to the best 3d printer for your work. Take time to research, review your needs, and select with confidence.

FAQ

What is the best way to maintain my 3d printer?

You should clean the nozzle and bed often. Lubricate moving parts. Check belts and screws for tightness. Replace worn parts quickly. Good maintenance helps your 3d printer last longer.

Can I use different filaments with my 3d printer?

Most printers support many filament types. Check your printer’s manual for compatible materials. Some filaments need higher temperatures or special beds. Always use the right filament for your project.

How safe is it to use a 3d printer at home?

Place your 3d printer in a well-ventilated area. Avoid touching hot surfaces. Use safety covers if available. Follow the manufacturer’s safety instructions. Good airflow reduces fumes and keeps you safe.

What projects can I make with a 3d printer?

You can create models, tools, toys, and replacement parts. Many users design custom items for school or work. The 3d process lets you turn ideas into real objects quickly.