You will see that a common fdm printer is different from other 3d printers because it is easy to use and has simple technology. Fused deposition modeling melts filament and builds objects one layer at a time. Other 3d printers, like resin-based ones, use UV light and liquid resin. Fdm printers are usually cheaper because the machines and materials cost less. Most common fdm printers can use many materials like PLA and ABS, so they are flexible. Fdm prints have lines you can see and less detail than some other 3d printers. But you get easy setup, little maintenance, and bigger build sizes.

Key Takeaways

FDM 3D printers melt plastic filament to make objects in layers. This process is simple and does not cost much. These printers can use many plastics like PLA, ABS, and PETG. This gives you choices for different projects. FDM printers are easier to use than resin or powder printers. They are also easier to take care of. This makes them good for beginners and schools. FDM prints have lines you can see and less detail. But they print faster and can make bigger things. FDM printers work well at home, in schools, and for small businesses. They do have some limits, like slower big prints and less fine detail.

FDM Basics

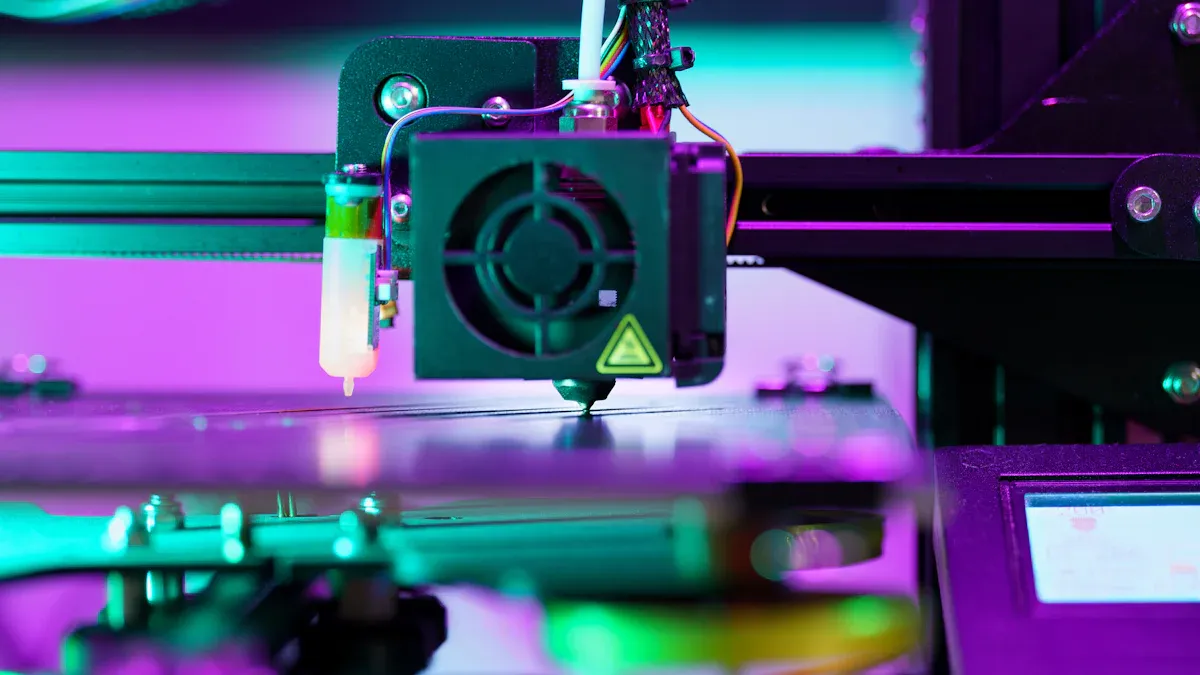

How FDM Works

Fused deposition modeling is the most popular 3d printing process. FDM melts plastic filament and pushes it through a hot nozzle. The nozzle moves in three directions to draw each layer. After one layer is done, the bed moves down a little. The printer then adds another layer on top. This way, you can make complex shapes with a 3d printer.

Tip: FDM 3d printers use thermoplastic filaments like PLA and ABS. These materials are simple to use and not expensive for most people.

Some fdm 3d printers have two extruders. This lets you print with two colors or materials at once. The heated bed helps the first layers stick well. This stops your print from warping or peeling off. Other 3d printers use lasers or UV light, but fdm uses heat and movement. This makes fdm printers cheaper and simple to take care of.

FDM Mechanical Types

There are different types of fdm printers you can buy. Each type has its own design. This changes how fast and well it prints. Here is a table to help you compare the main types of fdm printers:

|

Mechanical Type |

Description |

Popular Models/Brands |

Print Quality Impact |

|---|---|---|---|

|

Cartesian (Bedslinger, Box-Style) |

Moves axes one at a time; bedslinger moves bed in Y, box-style keeps bed still |

Prusa i3 MK3S+, Creality Ender 3, Ultimaker S3 |

Bedslinger: easy for beginners; Box-style: stable and precise |

|

CoreXY |

Uses belts for quick, smooth moves; bed only moves up and down |

Bambu Lab X1, Voron |

Fast prints, very smooth finish |

|

Delta |

Three towers move the extruder with arms |

Anycubic Delta |

Fast and smooth, but harder to set up |

|

Polar |

Bed spins and moves in circles |

Niche brands |

Different style, not used as much |

You will see brands like Prusa, Creality, Anycubic, and Bambu Lab a lot. These brands make fdm printers that are good quality and easy to use. When picking an fdm printer, think about what you need most. Do you want speed, accuracy, or something simple to use?

Common FDM Printer vs. Other 3D Printers

Print Process

One big difference is how each printer works. FDM printers melt plastic and draw each layer. SLA printers use light to make liquid resin hard. SLS printers use a laser to stick powder together. FDM needs extra supports for some shapes. SLS uses powder as support, so it can print tricky shapes.

|

Material Used |

Printing Process |

Support Structures |

Key Advantages |

|

|---|---|---|---|---|

|

FDM |

Thermoplastic filaments (PLA, ABS) |

Melts and pushes out filament through a hot nozzle, making layers |

Supports needed for overhangs |

Cheap, simple, fast for test prints |

|

SLA |

Liquid photopolymer resin |

Uses UV light to harden resin in layers |

Same resin for supports, easy to take off |

Very detailed, smooth prints |

|

SLS |

Powdered polyamides (like nylon) |

Laser melts powder layer by layer; powder holds the print |

Strong, complex shapes, no support trouble |

Note: FDM printers need careful setup for supports, but SLS does not. SLS is better for hard shapes.

Materials

Different 3D printers use different materials. FDM printers use plastic filaments like PLA, ABS, PETG, and TPU. SLA printers use liquid resin that hardens with UV light. SLS printers use powder, often nylon, but sometimes metal or ceramic.

- FDM uses plastic filaments.

- SLA uses liquid resin.

- SLS uses powder, sometimes metal or ceramic.

|

FDM (Fused Deposition Modeling) |

Other 3D Printing Methods |

|

|---|---|---|

|

Material Form |

Plastic filaments (like ABS, PLA) |

Powder (metal, ceramic), liquid resin, food, glass, more |

|

Processing Method |

Melts and pushes out filament in layers |

UV light, powder melting, or glue |

|

Material Variety |

Mostly plastics |

Many types: metals, ceramics, resins, organics |

|

Application Areas |

Test parts, working pieces |

Factories, medicine, food, tiny models |

FDM printers let you use many kinds of plastic. Other printers can use more materials, like metal or resin, but these are harder and cost more.

Cost

Cost is a big reason people pick FDM printers. FDM printers start at about $270 for a basic one. SLA printers cost more, and their resin is pricier than FDM filament. SLS printers are the most expensive, starting at $5,000, and their powder costs even more.

FDM filament costs $20 to $70 per kilogram. SLA resin costs more, and SLS powder is the priciest. FDM printers are cheap to fix. You only change small parts like nozzles or belts. SLA and SLS need special parts and expert help, which costs more.

- FDM is the cheapest way to start 3D printing.

- SLA and SLS cost much more.

Tip: If you want to try 3D printing at home or school, FDM is the best for your budget.

Print Quality

Print quality is not the same for every printer. FDM printers make parts with lines you can see. Curved parts may look like steps. SLA printers make very smooth and detailed prints. SLS printers make strong parts with a powdery look.

|

Factor |

FDM |

SLA |

SLS |

|---|---|---|---|

|

Medium (0.05–0.3 mm layers) |

High (0.02 mm layers) |

Medium-High |

|

|

Surface Quality |

Rough, lines you can see |

Very smooth, lots of detail |

Medium, powder feel |

|

Mechanical Properties |

Strength changes by direction |

Almost the same in all directions |

Strong, good for working parts |

|

Minimum Wall Thickness |

About 0.5 mm |

About 0.1 mm |

Can be thin, depends |

You can make FDM prints look better by using thinner layers, slower speeds, and more outer walls. Sanding or painting can hide lines. Still, FDM cannot match the detail of SLA or the strength of SLS.

Note: FDM prints can warp, shift layers, and need supports for overhangs. These problems are less common with SLA and SLS.

Speed and Maintenance

FDM printers are usually faster than SLA, especially for big prints. You can use thick layers to finish faster. SLA printers are slower because they use thin layers for more detail. SLS printers can print many things at once, but setup and cleaning take longer.

FDM printers are easy to care for. You clean the nozzle, check the bed, and change cheap parts like belts or nozzles. SLA printers need careful cleaning and handling sticky resin. SLS printers need experts for lasers and powder.

|

Technology |

Key Maintenance Tasks |

Suitability |

|

|---|---|---|---|

|

FDM |

Low and simple |

Clean, adjust, change nozzle or bed |

Great for beginners and schools |

|

SLA |

Higher |

Clean resin, cure prints, change film |

Needs more skill and care |

|

SLS |

Highest |

Handle powder, fix laser, expert needed |

Best for factories |

Tip: If you want easy care and fast prints, FDM is the best choice.

Practical Use of FDM 3D Printers

Applications

You can see 3d printers in lots of places now. FDM 3d printers are used at home, in schools, and in factories. Teachers use 3d printers to make models of things like planets or the brain. This helps students learn by seeing and touching, not just listening. Many schools use 3d printers in science and design classes.

In factories, fdm 3d printers help make test parts, tools, and real products. Companies in planes, medicine, and cars use 3d printers for strong, light parts. FDM lets you make tricky shapes without special tools or molds. This saves time and money, especially for small jobs or custom pieces.

Here is a table that shows how different groups use 3d printers:

|

Sector |

Examples of FDM Printer Use |

|---|---|

|

Education |

Models for teaching, hands-on science projects, and design learning |

|

Industry |

Prototypes, tools, spare parts, and finished products |

|

Private |

Affordable desktop 3d printers for home projects and small businesses |

User Experience

Fdm 3d printers are easier to use than many other types. Most have simple menus and easy steps to follow. Many printers now have things like auto bed leveling and simple filament loading. These features help you start fast and avoid mistakes.

Tip: If you are new to 3d printers, pick one with easy controls and lots of help online.

You can use phone apps or setup guides to learn. Many people say fdm 3d printers are less messy than resin ones. You do not need special chemicals or UV lights after printing. For beginners and kids, fdm 3d printers with Cartesian systems are easiest to set up. Cleaning and simple care keep your printer working well.

Ownership Costs

When you buy a 3d printer, think about more than just the price. FDM 3d printers cost less for both the machine and the materials. Filament is cheap and easy to keep. Maintenance is simple—clean the nozzle, check the bed, and update the software. You do not need fancy tools or special rooms.

- Total costs include the printer, filament, and basic care.

- FDM 3d printers are a good deal for test parts and small runs.

- Big 3d printers can cost much more, especially if you need special stuff.

You can use many kinds of filament, like PLA, ABS, PETG, and even bendy or mixed materials. This makes fdm 3d printers great for many projects at home or work.

Choosing FDM

When to Use FDM

Pick 3d printers with filament if you want something easy and cheap. These printers are good for home, school, and fun projects. You can make toys, models, tools, and small car parts. Many people like these printers because setup is simple and cleaning is quick. You do not need to use messy liquids or strong chemicals.

3d printers with filament work well for:

- Making special gifts or cool decorations

- Building boxes, holders, or cases for stuff

- Creating parts for hobbies, art, or science class

- Printing bendy things like phone cases or seals

- Making a few parts for testing or fixing things

You can pick from many plastics. PLA is good for easy things. PETG is strong and does not mind water. ABS is best if you need heat resistance. TPU is great for bendy prints. These printers let you try lots of ideas without spending much. Experts say they are best for people at home, hobby fans, and anyone who wants custom things fast.

Tip: If you want to print long, thin, or flat shapes, filament 3d printers are often better. They do not have as many problems with warping as other types.

Limitations

Filament 3d printers have some limits you should know. They cannot use every material or make every shape look perfect. You might see lines on your prints. Small details can be hard to get right. Big prints can take a long time, even days.

|

Limitation |

What It Means for You |

|---|---|

|

You may need to split big objects and glue them together |

|

|

Prints often show lines and may need sanding or painting |

|

|

Lower detail accuracy |

Fine details are harder to achieve than with other 3d printers |

|

Long print times for big parts |

Large objects take a lot of time to print |

|

Not ideal for mass production |

Making many copies is slow and costly |

|

Parts may break more easily along the layers |

|

|

Sensitive to temperature changes |

Prints can crack or warp if the room is too hot or cold |

You will need to take off supports and sometimes smooth the prints. If you want very smooth or super detailed models, resin or powder 3d printers might be better. For most home, school, or creative projects, filament 3d printers give you a good mix of price, material choices, and easy use.

You have many choices when it comes to 3d printers. FDM models stand out for low cost, easy maintenance, and a wide range of materials like PLA, ABS, and PETG. Other 3d printers, such as resin or SLS types, offer higher detail or stronger parts but cost more and need extra care.

Tip: Choose 3d printers based on your project’s needs. For quick prototypes, classroom use, or home projects, FDM 3d printers work well. If you need very fine details or special materials, look at other 3d printers. Always match your choice to your budget, material needs, and the level of detail you want.

FAQ

What makes 3d printers with FDM technology good for beginners?

You can start using 3d printers with FDM technology quickly. These 3d printers have simple controls and easy setup. You do not need special skills or tools. Many people learn to use 3d printers at home or in school with just a little practice.

Can you use different materials with 3d printers at home?

Yes, you can use many types of plastic with most 3d printers. You can try PLA, ABS, PETG, or even flexible filaments. These 3d printers let you pick the best material for your project, from strong parts to colorful models.

How do you keep 3d printers working well?

You should clean the nozzle and check the bed often. Replace worn parts when needed. Most 3d printers need only simple care. You can find guides online to help you fix small problems. Regular care keeps your 3d printers running smoothly.

Are 3d printers safe for kids to use?

3d printers are safe if you follow the rules. You should watch kids while they use 3d printers. Keep the printer in a well-ventilated space. Do not touch hot parts. Always read the manual before you start printing.

Why do some 3d printers cost more than others?

Some 3d printers have better parts, bigger build areas, or more features. High-end 3d printers can print faster or with more detail. Cheaper 3d printers work well for simple jobs. You should pick a printer that matches your needs and budget.