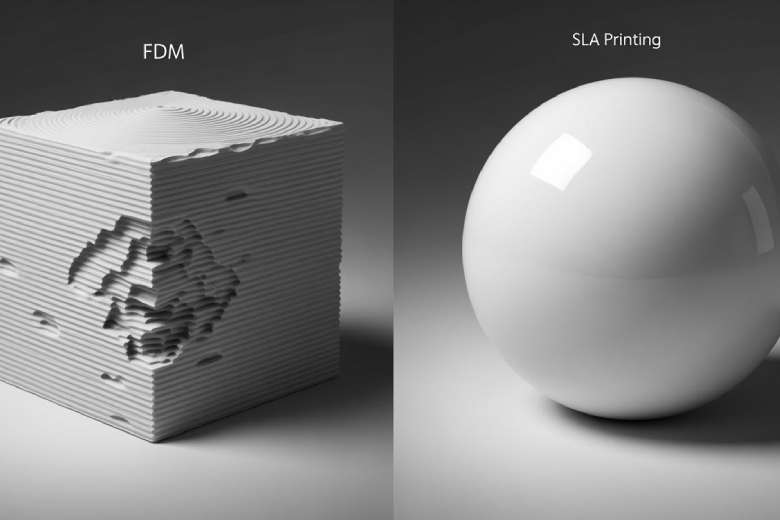

SLA printing creates a smoother and higher-quality surface finish than FDM. Many designers and engineers value surface finish because it affects how a part looks and performs. In 3d printing, a smooth surface can improve the appearance and function of the final 3d model. A high-quality surface often means fewer steps to prepare a part for use or display.

Key Takeaways

- SLA printing produces smoother and higher-quality surfaces than FDM printing, making it ideal for detailed models.

- FDM printing is more accessible and cost-effective, suitable for functional prototypes and larger models where surface finish is less critical.

- Layer height significantly affects surface finish; lower heights in FDM reduce visible lines, while SLA achieves finer details with thinner layers.

- Post-processing is often necessary for FDM prints to improve surface quality, while SLA prints usually require minimal finishing.

- Choosing between FDM and SLA depends on project needs, budget, and desired surface quality.

FDM and SLA Overview

What is FDM?

FDM stands for fused filament fabrication, a popular 3d printing technology. FDM printing uses a heated nozzle to melt and deposit plastic filament layer by layer. The printer builds the object from the bottom up, following a digital model. Many people choose FDM printing because it offers a simple process and works with a wide range of materials. This method of additive manufacturing often appears in schools, hobbyist workshops, and engineering labs. FDM printing creates strong parts but usually leaves visible layer lines on the surface.

What is SLA?

SLA 3d printing uses a different approach. SLA stands for stereolithography, a process that uses a laser or light source to cure liquid resin into solid layers. The printer directs the light to specific areas, hardening the resin one thin layer at a time. SLA 3d printing produces highly detailed and accurate parts. Many designers use SLA when they need smooth surfaces and fine features. This additive process works well for prototypes, dental models, and jewelry.

Technology Impact on Surface Finish

The mechanisms behind FDM and SLA 3d printing technology create clear differences in surface finish.

- FDM printing results in a rougher surface finish. The process uses thicker layers, usually between 0.1 to 0.3 mm. The extrusion of melted filament leaves visible layer lines on the printed object.

- SLA 3d printing provides a smoother finish. The printer cures much finer layers, often between 0.05 to 0.15 mm. This method allows for high-resolution prints with fewer visible lines.

Surface Finish Comparison: SLA vs. FDM

FDM Surface Finish Features

FDM printing creates parts by stacking layers of melted filament. This process often leaves visible layer lines on the surface. The finish of FDM parts depends on several factors, such as layer height, filament quality, and printer settings. Most FDM prints show a rougher surface finish compared to other 3d printing methods. The top layers can appear corrugated, while the bottom layers may feel smoother if no support structures touch them. Areas with support material usually have a rougher finish and may need extra work to improve the surface.

The following table shows typical surface roughness values for FDM printed parts:

|

Material |

Surface finish |

Ra (μm) |

Rz (μm) |

|---|---|---|---|

|

ASA |

As printed |

114.9 |

Layer height plays a major role in the visibility of lines on FDM prints. Lower layer heights, such as 0.05 to 0.15 mm, reduce the appearance of lines and create a smoother surface finish. Higher layer heights, above 0.2 mm, increase surface roughness and make lines more noticeable. The table below summarizes how layer height affects the finish:

|

Layer Height (mm) |

Effect on Visibility of Layer Lines |

Additional Notes |

|---|---|---|

|

0.05 - 0.15 |

Reduces visibility significantly |

High precision needs, smoother surfaces |

|

0.16 - 0.28 |

More pronounced lines |

Can weaken prints by 27% |

|

≥ 0.2 |

Increased surface roughness |

Suitable for functional parts, rapid prototypes |

Other factors also influence the finish of FDM prints:

- Inconsistent extrusion can create uneven lines.

- Temperature changes may cause surface defects.

- Gcode errors can introduce unwanted patterns.

- Filament quality and wall thickness affect layer line formation.

FDM printing often requires post-processing, such as sanding or vapor smoothing, to achieve a smooth surface finish. Even after these steps, the finish may not match the quality of SLA prints. FDM works well for functional parts and rapid prototypes, but it struggles to deliver highly detailed features or an excellent surface finish.

SLA Surface Finish Features

SLA 3d printing uses a laser or light source to cure liquid resin into solid layers. This technology produces parts with a much smoother surface finish than FDM. The layers in SLA prints are thinner, often between 0.05 and 0.15 mm, which helps create a nearly seamless appearance. SLA prints show fewer visible lines and can achieve highly detailed features and fine feature detail.

A direct comparison of surface roughness shows the difference in finish quality:

|

Technology |

Surface Roughness (Ra, μm) |

Statistical Significance |

|---|---|---|

|

SLA |

≈ 1.4 |

p < 0.001 |

|

FDM |

≈ 6 (after post-processing) |

p < 0.001 |

SLA technology enables high-detail parts with excellent surface finish. The UV laser allows for precise control, resulting in smoother surfaces and sharper details. Most SLA prints require little to no post-processing to achieve a display-ready finish. Designers often choose SLA when they need smooth surface finishes, high print quality, and detailed models.

The table below highlights the main differences in surface finish and print quality between SLA and FDM:

|

Feature |

SLA Technology |

FDM Technology |

|---|---|---|

|

Surface Finish |

Visible layer lines |

|

|

Detail and Accuracy |

Higher detail due to UV laser usage |

Lower detail, requires post-processing |

|

Post-Processing Needs |

Minimal, often not required |

Significant, sanding or vapor smoothing needed |

Causes of Surface Finish Differences

Materials and Process

The materials and process used in fdm and sla printing play a major role in the final surface finish. Fdm uses thermoplastic filaments, which the printer melts and extrudes layer by layer. This process often leaves visible lines and a rougher texture. Sla, on the other hand, cures liquid resin with a uv laser. This method produces high-resolution prints with smooth surfaces and fine detail. The table below highlights the differences in surface texture between these two 3d printing technologies:

|

Printing Process |

Surface Texture Characteristics |

|---|---|

|

fdm |

Produces visible layer lines and has limitations in achieving fine detail resolution, resulting in a rougher surface finish. |

|

sla |

Cures liquid resin with a uv laser, producing high-resolution parts with smooth surface finishes, ideal for precision and aesthetics. |

Sla printing stands out for its ability to deliver high dimensional accuracy and precision. Fdm printing, while accessible, cannot match the smoothness and detail of sla.

Layer Resolution

Layer resolution directly impacts the quality and smoothness of printed parts. Fdm printers typically achieve a minimum layer height of 0.1 to 0.4 mm. This range often results in visible layer lines and a less refined finish. Sla printers can reach a minimum layer height of 0.025 mm, which allows for smoother surfaces and better detail capture. The table below compares the minimum layer resolution and its effect on surface finish:

|

Printer Type |

Minimum Layer Resolution |

Surface Finish Impact |

|---|---|---|

|

fdm |

0.1 - 0.4 mm |

Visible layer lines |

|

sla |

0.025 mm |

Smoother surfaces |

Lower layer heights improve the vertical resolution and help achieve high dimensional accuracy. For curved or angled parts, thin layers reduce the stepping effect and create a more precise finish. Precision printing with sla results in high-resolution prints and superior dimensional accuracy.

Post-Processing Needs

Post-processing steps also affect the final surface finish and dimensional accuracy. Fdm prints often require several finishing techniques to improve quality:

- Support removal eliminates marks left by support structures.

- Sanding smooths out layer lines and imperfections.

- Priming and painting fill gaps and create a uniform appearance.

- Chemical smoothing, such as acetone treatment, dissolves surface flaws.

- Annealing enhances mechanical properties and reduces internal stresses.

Sla prints usually need less post-processing. Users may remove supports and polish the surface to enhance smoothness. Sometimes, filling small gaps with epoxy resin or autobody filler is necessary. Wet sanding and manual polishing can further improve the finish. Both fdm and sla post-processing steps can affect dimensional accuracy, especially when sanding or polishing changes the part’s shape. Sla printing generally requires fewer steps to achieve a high-quality surface, making it ideal for applications that demand high dimensional accuracy and precision.

Choosing Between FDM and SLA for Surface Finish

Best Uses for FDM

FDM printing offers a practical solution for many prototyping and production needs. Engineers and hobbyists often select FDM for its affordability and accessibility. This technology works well for functional prototypes, mechanical parts, and rapid design iterations. FDM printers handle a wide range of thermoplastic materials, making them suitable for testing fit and function in early design stages.

FDM excels in these scenarios:

- Rapid prototyping for mechanical components.

- Production of durable parts for engineering applications.

- Creation of large models where surface finish is less critical.

- Projects with limited budgets or tight timelines.

FDM parts often display visible layer lines and a coarse surface finish. Users must apply post-processing techniques such as sanding, grinding, or painting to improve the appearance. Achieving a smooth finish requires extra time and resources. The surface quality and detail accuracy of FDM printing remain slightly inferior to other 3d printing technologies. FDM stacks material layer by layer, which results in obvious patterns on the surface. Designers choose FDM when they prioritize speed, cost, and material versatility over high-quality parts with a flawless finish.

Tip: FDM printing suits projects where function matters more than aesthetics. For prototypes that need to withstand stress or testing, FDM provides reliable results.

Best Uses for SLA

SLA printing stands out for its ability to produce high-quality parts with exceptional surface finish. Designers and engineers rely on SLA when they need smooth surfaces, fine details, and high dimensional accuracy. SLA technology uses a UV laser to cure liquid resin, resulting in prints with minimal visible lines and superior finish.

Industries and applications that benefit most from SLA printing include:

|

Industry/Application |

Specific Uses |

|---|---|

|

Medical and Dental |

Anatomical models, guides, and housings where accuracy and surface quality are important. |

|

Consumer Electronics |

Cosmetic enclosures, light-pipes (with clear finishing), and small mechanisms for fit checks. |

|

Automotive and Aerospace |

Design validation models, aerodynamic/flow visualization, and ergonomic bucks. |

|

Industrial Equipment |

Fixtures, assembly aids, and patterns for downstream processes. |

SLA printing delivers high-quality parts for display models, prototypes with intricate features, and products that require a flawless surface finish. The technology enables designers to create detailed jewelry, dental models, and cosmetic prototypes. SLA prints often need minimal post-processing, which saves time and preserves dimensional accuracy.

Note: SLA printing is ideal for applications where appearance, detail, and surface finish are critical. When a project demands high-quality parts with smooth surfaces, SLA provides the best results.

Choosing between FDM and SLA depends on the specific requirements of each project. FDM offers cost-effective solutions for functional prototyping and large-scale models. SLA excels in producing high-quality parts with superior surface finish and detail. Designers should consider factors such as budget, desired finish, accuracy, and application needs before selecting a 3d printing technology.

Cost and Accessibility Factors

Cost of Achieving Smooth Surface Finish

FDM printing offers a lower entry cost for users who want to create parts with a moderate surface finish. The printers and materials for FDM are affordable, making this technology popular among hobbyists and schools. Achieving a smooth finish with FDM often requires extra steps such as sanding or chemical smoothing. These steps add time and may increase costs if users need special equipment or supplies. SLA printing provides a higher surface finish quality but comes with higher costs. The printers use advanced technology and require expensive resins. Users must also consider the cost of post-processing materials, such as solvents and UV curing equipment. The table below compares the cost and ideal use case for each technology:

|

Printer Type |

Cost |

Ideal Use Case |

|---|---|---|

|

FDM |

Low |

Functional parts and prototypes |

|

SLA |

High |

Intricate models requiring fine detail |

Time and Post-Processing

FDM printing produces parts quickly, but users spend extra time improving the surface finish. Sanding, priming, and painting can take several hours, especially for complex shapes. SLA printing streamlines post-processing for surface quality. After printing, users rinse parts in a solvent to remove excess resin. They then cure the parts under UV light to reach final strength and stability. This process is efficient for high-detail prototypes and models with smooth finishes. Most SLA prints, such as jewelry pieces, require washing in isopropyl alcohol and UV curing. The average time for these steps ranges from one to two hours. SLA printing saves time for users who need display-ready parts with minimal effort.

- FDM post-processing often involves sanding and painting, which can be time-consuming.

- SLA post-processing includes rinsing and UV curing, usually completed within two hours.

User Accessibility

FDM printing remains highly accessible to both hobbyists and professionals. The printers are easy to set up and operate, and the materials are widely available. Users can achieve a moderate surface finish with basic skills. SLA printing offers exceptional surface finish quality but presents more barriers to entry. The technology requires knowledge of resin chemistry and safe handling practices. SLA materials are not recyclable and may create waste, which can discourage some users. The cost of SLA materials is higher, and post-processing adds complexity. Safety concerns arise from the toxicity of many resins, so users need proper ventilation and protective equipment. The table below summarizes accessibility and surface finish quality for each technology:

|

Printer Type |

Accessibility |

Surface Finish Quality |

|---|---|---|

|

FDM |

High |

Moderate (requires post-processing) |

|

SLA |

Moderate |

High (exceptional detail and smooth surfaces) |

The table below highlights the main differences in surface finish between FDM and SLA:

|

Feature |

FDM |

SLA |

|---|---|---|

|

Surface Detail |

Lower detail, visible layer lines |

Higher detail, smoother finish |

|

Layer Height |

0.2–0.12 mm |

Starts at 0.102 mm |

|

Small Features |

Less capable |

Excellent for tiny features |

SLA printing delivers unmatched accuracy and a smooth surface finish, making it ideal for parts with fine details. FDM suits projects where cost and speed matter most. When choosing a method, users should consider the application’s objective, available post-processing options, and the importance of finish.

- Post-processing improves surface finish.

- Application goals guide technology selection.

- Part geometry and material affect finishing choices.

FAQ

What makes SLA prints smoother than FDM prints?

SLA printers use a laser to cure liquid resin in very thin layers. This process creates fewer visible lines and a smoother surface. FDM printers stack melted plastic, which leaves more noticeable layer lines.

Can FDM prints achieve a smooth finish like SLA?

FDM prints can look smoother after sanding, chemical smoothing, or painting. However, even with post-processing, FDM rarely matches the fine detail and smoothness of SLA prints.

Which technology is better for detailed models?

SLA printing produces higher detail and sharper features. Designers choose SLA for jewelry, dental models, and prototypes that need fine details. FDM works best for larger, functional parts.

Is SLA printing more expensive than FDM?

SLA printers and resins usually cost more than FDM printers and filaments. SLA also requires special post-processing materials. FDM offers a lower-cost option for most users.

Do both FDM and SLA prints need post-processing?

Both types may need post-processing. FDM prints often require sanding or smoothing to improve the surface. SLA prints usually need rinsing and UV curing, but they often need less work to look good.