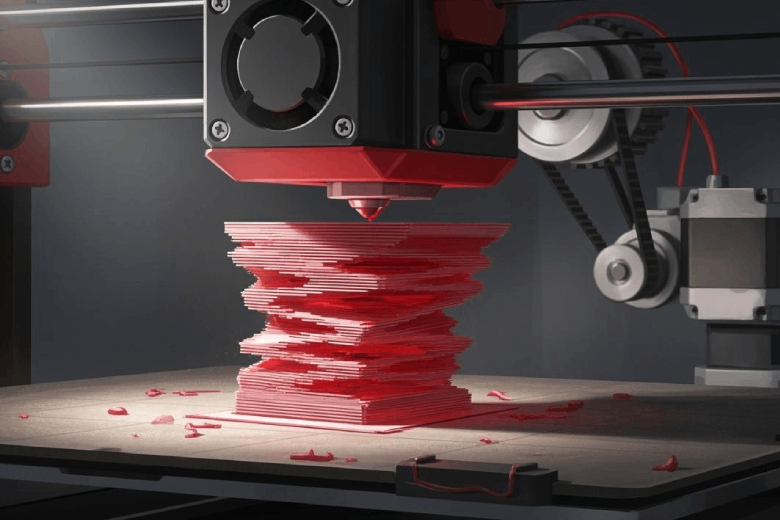

Layer shifting in 3d prints often frustrates those who expect smooth results. Mechanical issues such as loose belts or uneven tension can make the print head shift from its intended position. Electrical faults like overheating stepper motor drivers or incorrect voltage settings also contribute to 3d printer layer shift. Print settings and environmental factors, including vibrations and poor placement, lead to shifting and misaligned layers. The table below highlights common causes that affect the printer’s performance:

|

Cause |

Description |

|---|---|

|

Timing belts on the X and Y axes can stretch and lose tension, leading to shifts during printing. |

|

|

Overheating stepper motor drivers |

Can cause motors to skip steps, resulting in layer shifting. |

|

Vibrations from nearby machines |

Can cause shifts and layer separation if the printer is on an unstable surface. |

This article provides practical troubleshooting steps for anyone facing print head position problems in 3d printing.

Key Takeaways

- Check and maintain belt tension regularly. Loose belts can cause misaligned layers during printing.

- Ensure the printer is on a stable surface. Vibrations from nearby machines can lead to layer shifting.

- Adjust stepper motor voltage settings according to the printer's manual. Incorrect settings can cause the print head to lose position.

- Review slicer settings before printing. Proper configuration helps the print head move smoothly and prevents misalignment.

- Perform regular maintenance, including cleaning and lubricating moving parts. This keeps the printer running smoothly and reduces layer shifting.

Mechanical Causes of Layer Shifting

Loose Belts and Pulleys

Loose belts and pulleys often cause 3d printer layer shift. When the belt tension drops, the printer loses positional integrity, and the print head may shift unexpectedly. Users frequently report that insufficient belt tension leads to misaligned layers and defects in the final print. Mechanical inaccuracies from worn belts or pulleys can affect print quality significantly. Regular maintenance of belts and pulleys helps prevent layer shifting and keeps the 3d printer running smoothly.

Tip: Always check belt tension before starting a print. A tight belt transfers movement effectively and maintains layer alignment.

- Loose belts are a major cause of 3d printer layer shift.

- Insufficient tension can result in misaligned layers.

- Maintenance of belts and pulleys is essential for positional integrity.

Misaligned Rails

Misaligned rails disrupt the movement of the print head and can cause misaligned layers. A misaligned or loose frame leads to poor print quality and axis travel failures. Debris in the frame channels may cause the carriage to bounce, resulting in momentary axis shifts. If the obstruction is significant, it can halt the axis or derail it, directly impacting layer alignment and integrity.

Note: Cleaning the rails and frame channels regularly helps maintain positional integrity and prevents shifting.

Stiff Axles and Couplers

Stiff axles and couplers restrict smooth movement, which can cause the print head to lose its position. When axles or couplers do not move freely, the printer may experience layer shifting. This issue often results in misaligned layers and affects the overall integrity of the print.

Frame Instability

Frame instability reduces the printer’s ability to maintain positional integrity. A shaky or loose frame can cause the print head to shift during operation, leading to misaligned layers. Ensuring the frame is stable and secure helps prevent 3d printer layer shift and maintains the integrity of each layer.

Quick Checklist for Mechanical Adjustments:

- Check the printing profile for correct settings.

- Reduce printing speed below 60mm/s.

- Set travel speed to 100mm/s.

- Adjust retraction settings.

- Enable Z hop.

- Disable combing mode.

- Set the right belt tension.

A stable frame, smooth axles, and properly tensioned belts all contribute to the positional integrity of the 3d printer. Addressing these mechanical causes helps prevent shifting and ensures each layer aligns correctly.

Electrical Issues in 3D Printer Layer Shift

Stepper Motor Problems

Stepper motors play a key role in moving the print head and bed. When these motors do not receive the correct voltage or current, the printer may experience lost motor steps. This problem often leads to a 3d printer layer shift. Incorrect voltage settings can cause overheating or weak torque, making the layer misalign. Technicians recommend adjusting voltage settings (VREF) according to the printer’s manual. They also suggest using a multimeter for precise VREF calibration and monitoring motor temperature after adjustments. Regular recalibration helps maintain optimal motor performance.

Common stepper motor problems include:

- Incorrect voltage or current settings

- Overheating due to poor ventilation

- Insufficient torque causing the print head to shift

- Loose or poorly connected flat cables

- Mechanical resistance in the motor

To diagnose stepper motor issues, users should:

- Check if the flat cable connects properly to the Y motor driver.

- Inspect the Y carriage for smooth movement.

- Test the stepper motor’s resistance by manually rotating the pulley.

Driver Overheating

Driver overheating remains a frequent cause of layer misalignment in 3d printing. When stepper drivers overheat, they can skip steps, resulting in a shift of the layer position. Dust buildup and poor ventilation can make overheating worse. Accurate torque is essential for proper motor function, so keeping drivers cool helps prevent layer shifting.

Tip: Place the printer in a well-ventilated area and clean dust from electronics regularly to reduce overheating risk.

Power Supply Faults

Power supply faults can disrupt the flow of electricity to the motors and drivers. Sudden drops or spikes in voltage may cause the printer to lose position, leading to misaligned layers. Technicians advise checking the power supply for stable output and replacing faulty units. A reliable power supply ensures consistent movement and reduces the chance of a layer shift during a 3d print.

Note: Stable power keeps the printer running smoothly and helps prevent lost motor steps.

Electrical issues such as stepper motor problems, driver overheating, and power supply faults often cause 3d printer layer shift. Addressing these problems helps maintain accurate layer positioning and improves overall print quality.

Print Settings and Layer Shifting

High Print Speed

Many users believe that high print speed causes layer shifting in 3d printing. However, studies show that print speed does not statistically increase the likelihood of a shift. The strength and behavior of 3d printed specimens remain consistent at different speeds. The stress-deflection response and fracture strength do not change much when the printer operates faster. Still, some users report loud bumps during printing, which may link to mechanical issues rather than speed itself. The print head can misalign if belts are loose or motors lack strength.

Tip: If the printer makes loud noises or the print head moves erratically, check mechanical components before adjusting print speed.

Acceleration and Jerk

Acceleration and jerk settings control how quickly the printer changes direction. If these values are too high, the print head may move abruptly, causing the layer to shift. Sudden changes in direction put stress on the printer’s motors and belts. The print head can lose its position, resulting in misaligned layers. Input Shaper firmware sometimes affects acceleration, and users have reported layer shifting after enabling this feature. Adjusting acceleration and jerk to moderate levels helps maintain smooth movement and proper layer alignment.

- High acceleration can cause the print head to skip steps.

- Excessive jerk settings may lead to sudden shifts in the layer.

- Moderate values improve stability and reduce shifting.

Slicer Configuration Errors

Slicer configuration errors often result in layer shifting during 3d printing. Incorrect settings can make the printer struggle to keep the print head aligned. Common mistakes include setting high print speed, improper belt tension, and loose pulleys. These errors prevent the printer from controlling the print head accurately, causing the layer to misalign.

Note: Always review slicer settings before starting a print. Proper configuration ensures the print head moves smoothly and each layer aligns correctly.

Common slicer errors linked to layer shifting:

- High print speed makes motors struggle.

- Incorrect belt tension causes slipping or friction.

- Loose pulleys prevent accurate movement of the print head.

Careful adjustment of print settings, acceleration, and slicer configuration helps prevent layer shifting. Regular checks keep the printer working well and ensure each layer stays in place.

Environmental and External Factors

Printer Vibrations

Vibrations from nearby equipment or unstable surfaces often cause a 3d printer to lose accuracy. Even small movements can make the print head move out of alignment, resulting in a layer shift. The printer must sit on a stable surface to avoid unwanted motion. People sometimes overlook the impact of vibrations, but these can disrupt the layer structure and ruin a 3d print.

Tip: Place the printer in a quiet area away from heavy machinery. Check that the table or stand does not wobble during operation.

|

Impact on Layer Shifting |

Recommendation |

|

|---|---|---|

|

Temperature Fluctuations |

Causes thermal expansion/contraction of components |

Maintain stable room temperature and use insulated enclosures. |

|

Nearby Vibrations |

Can affect print quality, though may seem insignificant |

Ensure stable printing environment. |

External Force or Impacts

Accidental bumps or touches during printing can cause the print head to move suddenly. This movement leads to a layer shift and misalignment. People should avoid touching the printer while it operates. Pets or children near the machine increase the risk of external force affecting the layer position.

- Keep the printer in a secure location.

- Prevent access by pets and children during printing.

Temperature Fluctuations

Temperature changes in the room can affect the 3d printer’s components. Sudden drops or rises in temperature cause parts to expand or contract. This movement can make the print head lose its position and shift the layer. Stable room temperature helps maintain consistent layer alignment.

Note: Use an insulated enclosure to protect the printer from drafts and temperature swings.

Nozzle Scratches and Suction Force

The nozzle sometimes drags across the print surface or pulls on the material. This action can shift the layer and cause defects. Scratches or suction force from the nozzle may result from incorrect Z offset or poor bed leveling. Regular calibration and maintenance reduce the risk of layer misalignment.

- Print in well-ventilated spaces or within an enclosure to minimize environmental impacts.

- Regularly maintain and calibrate the printer to prevent layer shifts.

- Check printer calibration and secure all parts.

- Keep the machine on a stable surface to avoid layer separation.

- Keep firmware and slicing software updated.

- Optimize motion settings, including travel speeds and paths.

Environmental and external factors play a major role in layer shifting. People who control vibrations, temperature, and external impacts help their 3d printer produce accurate layers.

Troubleshooting 3D Prints with Layer Shift

Step-by-Step Checks

A clear troubleshooting checklist helps users quickly identify and fix 3d printer layer shift. Many people find that following a logical sequence improves results and saves time. The steps below guide users through the most common solutions for layer shifting in 3d prints:

- Inspect the print head and rails for debris or obstructions. Remove any dust or particles that could block smooth movement.

- Check belt tension and alignment. Adjust belts if they feel loose or uneven. Proper tension prevents the print head from losing its position.

- Examine pulleys and couplers. Tighten any loose screws or bolts to secure the print head.

- Test the movement of each axis by gently moving the print head. It should glide smoothly without resistance.

- Review print settings in the slicer. Lower print speed and acceleration if the print head skips or shifts.

- Monitor the printer during operation. Listen for unusual noises or vibrations that may signal a problem.

- Confirm the power supply delivers stable voltage. Replace it if the printer shuts down or restarts unexpectedly.

- Update firmware and software to the latest versions. New updates often fix bugs that cause layer shifting.

- Calibrate stepper motors and check for overheating. Motors should stay cool and move the print head accurately.

- Secure the printer on a stable surface. Avoid placing it near heavy machinery or in high-traffic areas.

Users often report better print quality after cleaning the optical window and maintaining the x-axis. These steps resolve many issues related to layer shifting.

Maintenance Tips

Regular maintenance routines reduce the risk of 3d printer layer shift and keep 3d prints consistent. Technicians recommend the following actions to maintain optimal performance:

- Recalibrate and level the build plate before every print. This ensures even layers and strong adhesion.

- Remove dust and debris from the build plate and nozzle. Clean surfaces improve bed adhesion and prevent the print head from dragging material.

- Tighten all screws and bolts. A secure frame prevents the print head from shifting during operation.

- Lubricate moving parts, such as rails and axles. Lubrication reduces friction and noise, allowing the print head to move smoothly.

- Check and adjust belt tension regularly. Proper tension keeps the print head in the correct position.

- Clean and lubricate the printer every 30 minutes to 1 hour during long print sessions. This prevents buildup that can cause shifting.

- Perform deep cleaning, firmware updates, and component inspections every 1-2 hours as needed.

- Calibrate stepper motors (E-steps) for accurate movement on all axes.

- Inspect and tighten motor fasteners and set-screws to secure pulleys.

- Keep firmware and slicing software updated for the best performance.

Preventing Future Layer Shifting

Preventing future shifting in 3d prints requires a proactive approach. Users who follow these strategies see fewer problems and better results:

- Maintain belts and pulleys by checking for proper tension and alignment.

- Clean and lubricate motion components to reduce friction and prevent jams.

- Avoid aggressive speed settings that stress the print head and motors.

- Improve first layer and bed adhesion by recalibrating the build plate and cleaning the nozzle.

- Keep the printer in a stable environment, away from vibrations and temperature swings.

- Secure the bed and frame to avoid movement during printing.

- Adjust print speed to reduce stress on the motors and prevent the print head from losing its position.

- Prevent collisions by keeping the print area clear of tools, debris, and other objects.

- Implement a maintenance checklist, especially in school or shared environments, to ensure all users follow best practices.

Many users notice a significant improvement in print quality after adopting these prevention strategies. Consistent care and attention to detail help avoid layer shifting and keep 3d prints accurate.

A reliable troubleshooting checklist, regular maintenance, and smart prevention strategies address the most common causes of 3d printer layer shift. These steps help users maintain the correct position of the print head and produce high-quality 3d prints every time.

Layer shift in 3d prints often results from mechanical, electrical, and environmental factors. Regular checks and maintenance help prevent misalignment and improve layer quality. Studies show that simple adjustments resolve most layer issues. The table below highlights common causes and solutions for layer shifting:

|

Cause of Layer Shifting |

Solution |

|---|---|

|

External force or filament changes |

Remove obstacles from axes and use video to spot problems |

|

High viscosity filament |

Dry filament, use prime tower, adjust hotbed temperature |

|

Excessive print speed |

Enable auto-recovery, clean rods |

A 3d printer benefits from cleaning, tightening, and recalibrating. Users who follow these steps see fewer shift problems and more consistent layer alignment.

FAQ

Why do layers shift only in one direction?

Layer shifting in one direction often points to a mechanical problem. The belt or pulley on that axis may be loose. Users should check for worn parts and tighten all screws.

Can firmware updates fix layer shifting?

Firmware updates sometimes resolve bugs that cause layer shifting. They may improve motor control and stability. Users should always install the latest firmware for best results.

What should users do if layer shifting happens mid-print?

Users should pause the print and inspect the printer. They need to check for loose belts, pulleys, or obstructions. Restarting the print after fixing the issue often prevents further shifting.

Does print speed always cause layer shifting?

High print speed does not always cause layer shifting. Mechanical issues like loose belts or weak motors usually create the problem. Users should check hardware before lowering speed.