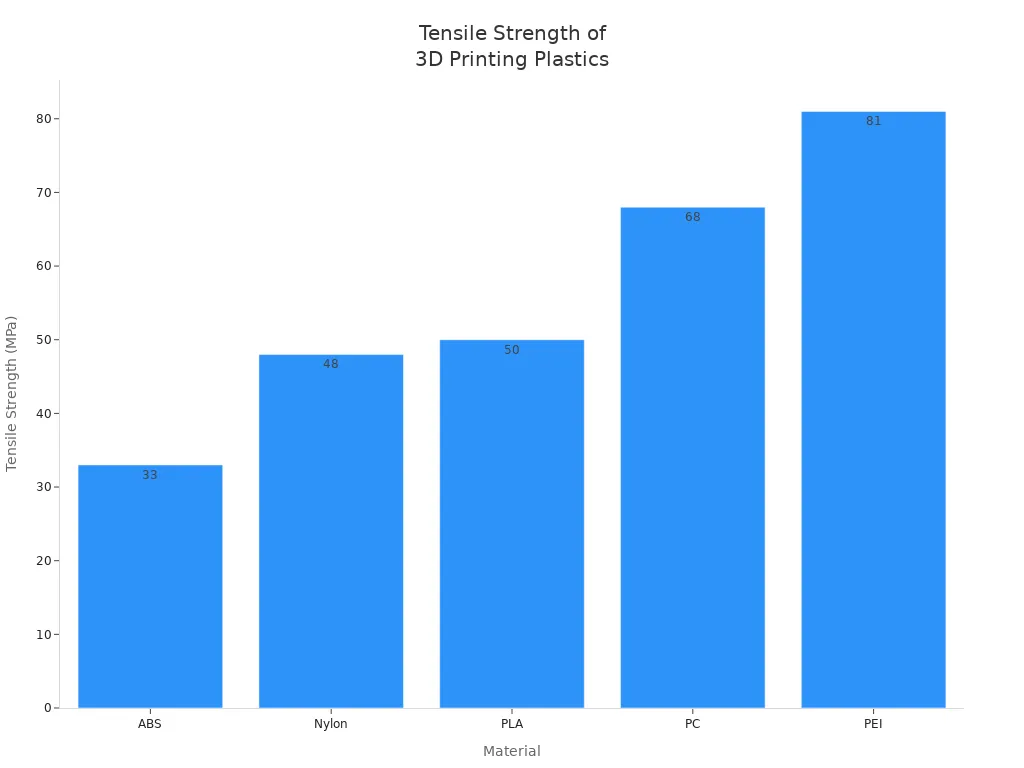

Polycarbonat ist der stärkste gängige Kunststoff für den 3D-Druck und erreicht Werte von bis zu 9.800 psi Metalle wie Aluminium sind Kunststoffen in speziellen Anwendungsbereichen hinsichtlich der Zugfestigkeit überlegen. Die Festigkeit von Materialien kann sich auf Zugfestigkeit, Schlagfestigkeit oder allgemeine Haltbarkeit beziehen. Polycarbonat bietet eine hohe Festigkeit, während PLA und Nylon ebenfalls gute Ergebnisse liefern. Die folgende Tabelle vergleicht die Zugfestigkeit gängiger Materialien:

| Material | Zugfestigkeit (MPa) | Zugfestigkeit (psi) |

|---|---|---|

| ABS | 33 | 4.700 |

| Nylon | 48 | 7.000 |

| PLA | 50 | 7.250 |

| PC | 68 | 9.800 |

| PEI | 81 | 11.735 |

Wichtigste Erkenntnisse

- Polycarbonat ist das stärkste gängige 3D-Druckmaterial und eignet sich daher ideal für Funktionsteile, die Belastungen standhalten müssen.

- Die Wahl des richtigen Filaments hängt von den Projektanforderungen ab, einschließlich Festigkeit, Flexibilität und Beständigkeit gegenüber Hitze oder Chemikalien.

- Höhere Füllgrade und geringere Schichthöhen verbessern die Festigkeit von 3D-gedruckten Teilen und machen sie dadurch haltbarer.

- Die Ausrichtung der Teile während des Druckvorgangs beeinflusst die Festigkeit; die Ausrichtung der Teile zur Aufnahme von Kräften entlang der XY-Ebene erhöht die Haltbarkeit.

- Das Experimentieren mit verschiedenen Materialien und Druckeinstellungen hilft dabei, die besten Ergebnisse für Ihre 3D-Druckprojekte zu erzielen.

Festigkeit der Werkstoffe im 3D-Druck

Definition der Materialfestigkeit

Die Materialfestigkeit im 3D-Druck beschreibt, wie gut ein gedrucktes Bauteil Kräften standhält, ohne zu brechen oder sich zu verformen. Ingenieure und Designer betrachten verschiedene Eigenschaften, um diese Festigkeit zu messen. Diese Eigenschaften helfen ihnen bei der Auswahl des passenden Materials. rechter Filament für jedes Projekt.

| | Beschreibung |

|---|---|

| | |

| Zugmodul | Bezieht sich auf die Steifigkeit des Materials; ein höherer Modulwert bedeutet ein steiferes Material. |

| Dehnung (%) | Gibt die Duktilität an; ein höherer Prozentsatz bedeutet, dass sich das Material stärker dehnen lässt, bevor es bricht. |

| Härte | Gemessen wird die Härte von Metallen auf der Rockwell-Skala bzw. die Härte von Polymeren auf der Durometer-Skala; höhere Werte weisen auf härtere Materialien hin. |

| Wärmeablenktemperatur (HDT) | Die Temperatur, bei der sich ein starrer Werkstoff unter einer bestimmten Belastung verformt. |

Hinweis: Die Streckgrenze gibt die Spannung an, die ein Material aushält, bevor es sich dauerhaft verformt. Die Bruchfestigkeit gibt an, wie viel Kraft erforderlich ist, um das Material zu brechen.

Die Festigkeit von Materialien hängt von mehr als nur der Art des Filaments ab.Mehrere Faktoren beeinflussen die Festigkeit eines 3D-gedruckten Bauteils:

| Faktor | Beschreibung |

|---|---|

| Materialauswahl | Die Art des verwendeten Materials, wie z. B. ABS, PLA oder industrietaugliche Thermoplaste, beeinflusst die Festigkeit. |

| Tragwerksplanung | Die Konstruktion des Bauteils beeinflusst die Kraftverteilung und kann die Festigkeit erhöhen oder verringern. |

| Teileausrichtung | Die Ausrichtung während des Druckvorgangs beeinflusst die Schichthaftung, die für die Festigkeit entscheidend ist. |

| Drucken | Die gewählte Druckmethode und die Einstellungen können die endgültige Festigkeit des Bauteils beeinflussen. |

| Füllprozentsatz | Bestimmt, wie massiv das Bauteil ist; eine höhere Füllung erhöht im Allgemeinen die Festigkeit. |

| Schichthöhe | Dünnere Schichten können aufgrund der besseren Haftung der Schichten zu festeren Bauteilen führen. |

| Post | Techniken wie Schleifen und Beschichten können die Oberflächenfestigkeit verbessern. |

| Druckgeschwindigkeit | Langsamere Drehzahlen ermöglichen eine bessere Erwärmung und Aushärtung, was zu festeren Bauteilen führt. |

| Schalendicke | Durch eine Erhöhung der Wandstärke lassen sich Zugfestigkeit und Schlagfestigkeit deutlich verbessern. |

Standardisierte Tests helfen bei der Messung die Festigkeit von Materialien im 3D-Druck. Diese Tests liefern zuverlässige Daten zum Vergleich verschiedener Filamente:

| Messtechnik | Beschreibung |

|---|---|

| Hochtemperatur-Zugprüfung | Bewertet die Festigkeit des Materials bei erhöhten Temperaturen, was für Anwendungen wie Motorkomponenten von entscheidender Bedeutung ist. |

| Bruchzähigkeitsprüfung | Misst den Widerstand des Materials gegen Rissausbreitung, was für Bauteile unter Stoßbelastung wichtig ist. |

| Ermüdungsprüfung | Analysiert das Verhalten des Materials unter wiederholten zyklischen Belastungen, was für Bauteile relevant ist, die kontinuierlichen Vibrationen ausgesetzt sind. |

Stärkste 3D-Druckmaterialien

Manche Filamente zeichnen sich durch ihre hohe Festigkeit aus. Polycarbonat, kohlenstofffaserverstärkte Filamente und bestimmte technische Kunststoffe bieten hervorragende Eigenschaften. Die Festigkeit von Materialien wie PEEK, Nylon und kohlenstofffaserverstärkten Filamenten macht sie für anspruchsvolle Anwendungen beliebt.

| Filamenttyp | |

|---|---|

| SPÄHEN | 7.250 |

| Nylon | 7.000 |

| Kohlenstofffaserverstärkt | 6.000 - 8.000 |

Polycarbonat und PEEK weisen beide eine hohe Festigkeit auf und sind daher optimale Werkstoffe für den 3D-Druck. Nylon bietet ebenfalls ein gutes Verhältnis von Festigkeit und Flexibilität. Kohlenstofffaserverstärkte Filamente vereinen die Festigkeit von Materialien wie Nylon oder PLA mit der zusätzlichen Steifigkeit von Kohlenstofffasern.Diese robusten 3D-Druckmaterialien eignen sich gut für Teile, die hohen Belastungen oder wiederholtem Gebrauch standhalten müssen.

Metalle wie Aluminium bieten noch höhere Festigkeit und Haltbarkeit. Sie erfordern jedoch spezielle Drucker und sind mit höheren Kosten verbunden. Kunststoffe bieten mehr Gestaltungsfreiheit und lassen sich einfacher verarbeiten. Die folgende Tabelle vergleicht die mechanischen Eigenschaften von Kunststoffen und Metallen im 3D-Druck:

| | Kunststoffe | Metalle |

|---|---|---|

| Stärke | Im Allgemeinen niedriger als bei Metallen | |

| Haltbarkeit | Kann für spezifische Bedürfnisse angepasst werden | Oft haltbarer als Kunststoffe |

| Anisotropie | Weniger ausgeprägt | Weist aufgrund des Schichtaufbaus anisotrope Eigenschaften auf. |

| Designflexibilität | Hohe Qualität, ermöglicht individuelle Anpassung | Im Vergleich zu Kunststoffen begrenzt |

Bei der Auswahl robuster 3D-Druckmaterialien sollten Anwender die für ihr Projekt benötigte Festigkeit berücksichtigen. Die Materialfestigkeit kann je nach Druckverfahren, Bauteildesign und Nachbearbeitungsschritten variieren. Durch das Verständnis dieser Faktoren kann jeder das richtige Filament für stabile und zuverlässige 3D-gedruckte Teile auswählen.

Überblick über gängige 3D-Druckmaterialien

PLA

PLA steht für eins PLA ist eines der beliebtesten 3D-Druckmaterialien. Es bietet eine gute Materialfestigkeit und lässt sich leicht verarbeiten. PLA eignet sich gut für Prototypen und Dekorationsgegenstände. Die folgende Tabelle zeigt die wichtigsten Eigenschaften:

| | Wert |

|---|---|

| 37 MPa | |

| Verlängerung | 6% |

| Biegemodul | 4 GPa |

| Dichte | 1,3 g/cm³ |

| Schmelzpunkt | 173 °C |

| Glasübergangstemperatur | 60°C |

PLA bietet eine mäßige Haltbarkeit, kann aber unter Belastung spröde werden. Es verträgt hohe Temperaturen nicht gut.

ABS

ABS ist ein weiteres gängiges Material für den 3D-Druck. Es bietet eine höhere Schlagfestigkeit und Zähigkeit als PLA.

- ABS hat eine Charpy-Scheibe Schlagfestigkeit von 12,6 ± 1,1 kJ/m², deutlich höher als die 2,7 ± 0,2 kJ/m² von PLA.

- ABS ist widerstandsfähiger gegen mechanische Belastungen und bricht seltener.

ABS eignet sich für Funktionsteile, die eine höhere Haltbarkeit und Festigkeit erfordern.

PETG

PETG vereint die einfache Handhabung von PLA mit der Robustheit von ABS. Dieses Filament bietet hohe Materialfestigkeit und Flexibilität.

- PETG widersteht Stößen und Biegungen, ohne zu brechen..

- Es behält seine strukturelle Integrität auch unter Belastung bei.

- PETG ist beständig gegen UV-Strahlung und Witterungseinflüsse und eignet sich daher für den Außeneinsatz.

- Das Filament weist eine beeindruckende Hitzebeständigkeit auf und lässt sich leicht drucken.

PETG eignet sich gut sowohl für Anfänger als auch für Experten, die langlebige 3D-Druckmaterialien benötigen.

Nylon

Nylonfilamente liefern hohe Festigkeit und Flexibilität. Dieses Material ermöglicht das Biegen von Bauteilen ohne Bruch und bietet dauerhafte mechanische Festigkeit. R-Nylon AQ27000-Filamente erreichen eine Streckgrenze von 76,20 MPa, während handelsübliche Nylonfilamente Werte zwischen 32 MPa und 48 MPa aufweisen. Dank seiner Schlagfestigkeit eignet sich Nylon ideal für anspruchsvolle Projekte und industrielle Anwendungen.

Polycarbonat (PC)

Polycarbonat zeichnet sich unter den 3D-Druckmaterialien durch seine außergewöhnliche Festigkeit aus. Die Zugfestigkeit von Polycarbonat-Filamenten übersteigt 5200 PSI und macht es damit zu einer der stärksten Optionen für 3D-Druckerfilamente. PC bietet eine hohe Schlagfestigkeit und ist temperaturbeständig, wodurch es sich ideal für technische und mechanische Bauteile eignet.

Kohlenstofffaserfilamente

Kohlenstofffaserfilamente mischen Standardkunststoffe mit Kohlenstofffasern, um die Materialfestigkeit zu erhöhen. Diese Filamente können Erhöhung der Zugfestigkeit um 30-50% Die Biegefestigkeit erhöht sich um 25–40 %. Die Steifigkeit kann um 50–100 % steigen, wodurch Bauteile höheren Belastungen standhalten können. Kohlenstofffaserfilamente verbessern zudem die Dimensionsstabilität und Hitzebeständigkeit und machen sie so zu robusten Werkstoffen für Funktions- und Strukturbauteile.

Photopolymere und technische Kunststoffe

Photopolymere und technische Kunststoffe bieten ein breites Spektrum an Festigkeit und Haltbarkeit. Robuste Verbundkunststoffe können viele Standardmaterialien für den 3D-Druck in ihrer Leistungsfähigkeit übertreffen.

| Harztyp | Zugfestigkeit (MPa) | Biegefestigkeit (MPa) | Schlagfestigkeit (J/m) |

|---|---|---|---|

| Standardharze | 20–30 | 50–60 | 17–20 |

| Robust/Ingenieurwesen | 55–90 | 80–100 | 41–48 |

| Kompositharze | 70–90+ | 150–170 | N/A |

Diese Harze eignen sich für Anwendungen, die eine hohe Materialfestigkeit und Haltbarkeit erfordern.

Metallfäden (Aluminium)

Metallische Filamente, beispielsweise auf Aluminiumbasis, bieten eine deutlich höhere Festigkeit als die meisten Kunststoffe. Aluminiumbasierte Filamente erreichen Zugfestigkeiten zwischen 268 und 345 MPa. Sie sind jedoch wesentlich teurer als Hochleistungskunststoffe. Diese Filamente eignen sich am besten für Spezialbauteile, die maximale Festigkeit und Haltbarkeit erfordern.

Tipp: Bei der Auswahl von 3D-Druckmaterialien sollten Sie stets darauf achten, dass die Festigkeit und Haltbarkeit des Filaments den Anforderungen des Projekts entsprechen.

Festigkeitsvergleich von 3D-Druckmaterialien

Die Wahl des richtigen 3D-Druckfilaments hängt vom Verständnis des Festigkeitsvergleichs verschiedener Materialien ab. Jedes Filament bietet einzigartige mechanische Eigenschaften, die das Verhalten des gedruckten Bauteils beeinflussen. Dieser umfassende Vergleich hebt die wichtigsten Faktoren hervor: Zugfestigkeit, Schlagfestigkeit, Flexibilität, Temperatur- und Chemikalienbeständigkeit sowie Schichthaftung.

Zugfestigkeit

Die Zugfestigkeit gibt an, wie viel Zugkraft ein Material aushält, bevor es bricht. Eine hohe Zugfestigkeit bedeutet, dass das Filament mehr Belastungen standhält.Viele hochfeste FDM-Filamente, wie Polycarbonat und Nylon, weisen eine hohe Zugfestigkeit auf. Die folgende Tabelle vergleicht die Zugfestigkeitswerte für gängige 3D-Druckmaterialien:

| Material | Zugfestigkeit (MPa) |

|---|---|

| 50-60 | |

| PETG | 40-50 |

| ABS | 34-36 |

| Nylon | 50-80 |

| Polycarbonat | 60-70 |

Nylon zeichnet sich durch seine hohe Zugfestigkeit von bis zu 80 MPa aus. Polycarbonat bietet ebenfalls gute Eigenschaften und ist daher eine Top-Wahl für Bauteile, die eine hohe Zugfestigkeit erfordern. PLA und PETG bieten eine mittlere Zugfestigkeit und eignen sich für Prototypen und weniger anspruchsvolle Anwendungen. ABS weist eine geringere Zugfestigkeit auf, gleicht dies aber durch andere Stärken aus.

Hinweis: Eine hohe Zugfestigkeit ist unerlässlich für Teile, die Dehnungs- oder Zugkräften widerstehen müssen, wie z. B. Halterungen, Zahnräder und mechanische Verbindungen.

Schlagfestigkeit

Die Schlagfestigkeit gibt an, wie gut ein Material plötzliche Stöße oder Kräfte absorbiert, ohne zu brechen. Diese Eigenschaft ist wichtig für Teile, die während des Gebrauchs herunterfallen oder gegen etwas stoßen könnten. Die folgende Liste vergleicht die Schlagfestigkeit gängiger 3D-Druckmaterialien:

- ABS: Steif und schlagfest, Ideal für Anwendungen mit hoher mechanischer Beanspruchung.

- TPU: Flexibel und äußerst strapazierfähig, bekannt für seine Stoßdämpfung und Schlagfestigkeit.

- PETG: Robust und leicht zu bedrucken, stoßfest und geeignet für funktionale Prototypen.

- PA (Nylon): Hohe Festigkeit und ausgezeichnete Schlagfestigkeit, geeignet für anspruchsvolle Anwendungen.

- PAHT CF15: Das stärkste der aufgeführten Materialien, mit hoher Schlagfestigkeit und Hitzebeständigkeit, geeignet für extreme Bedingungen.

- PP: Leicht und dennoch robust, mit guter Schlagfestigkeit, geeignet für Anwendungen mit wiederholter Nutzung.

- PP GF30: Erhöhte Festigkeit und Steifigkeit dank Glasfaser, geeignet für raue Umgebungen.

ABS und PETG bieten beide eine gute Schlagfestigkeit und eignen sich daher gut für Funktionsteile. Nylon zeichnet sich durch hohe Schlagfestigkeit aus und ist somit in anspruchsvollen Umgebungen von Vorteil. TPU besticht durch seine Flexibilität und Stoßdämpfung, während PAHT CF15 unter extremen Bedingungen hervorragende Ergebnisse liefert.

Flexibilität und Robustheit

Flexibilität und Zähigkeit beschreiben, wie gut sich ein Material biegt oder Energie absorbiert, ohne zu brechen. Zähe Materialien sind rissbeständig und halten wiederholter Belastung stand.Die folgende Tabelle fasst die Flexibilität und Zähigkeit wichtiger Filamente zusammen:

| Glühfaden | Vorteile | Nachteile | Optimale Einsatzmöglichkeiten |

|---|---|---|---|

| Nylon | Hohe Zähigkeit, Flexibilität und Verschleißfestigkeit; hervorragend geeignet für bewegliche oder ineinandergreifende Teile; beständig gegen viele Chemikalien und Öle | Hygroskopisch (muss trocken gelagert werden); erfordert hohe Drucktemperatur und Haftvermittler für das Druckbett. | Zahnräder, Scharniere, Schnappverbindungen, Buchsen oder mechanische Verbindungen |

| PETG | Robust, stoßfest, leicht biegsam | Nicht so flexibel wie TPU oder TPE | Mechanische Teile, die eine gewisse Haltbarkeit mit etwas Nachgiebigkeit erfordern. |

Nylon ist für seine Robustheit und Flexibilität bekannt. Es eignet sich gut für Zahnräder, Scharniere und bewegliche oder zusammensteckbare Teile. PETG bietet eine Kräftegleichgewicht und eine geringe Biegsamkeit machen es zu einer guten Wahl für langlebige mechanische Teile. Diese robusten Polymere tragen zur Herstellung von Teilen bei, die länger halten und unter Belastung besser funktionieren.

- Nylon: Robust, verschleißfest, halbflexibel; am besten geeignet für Funktionsprototypen, Zahnräder und unter Belastung stehende Teile.

- PETG: Robust, schlagfest, leicht biegsam; ideal für mechanische Teile, die Haltbarkeit bei gleichzeitiger Flexibilität erfordern.

Temperatur- und Chemikalienbeständigkeit

Temperatur- und Chemikalienbeständigkeit bestimmen, wie gut ein Material Hitze oder Chemikalien standhält. Manche Filamente können sich bei hohen Temperaturen oder aggressiven Chemikalien verformen oder an Festigkeit verlieren. Die folgende Tabelle vergleicht diese Eigenschaften:

| Material | Wärmeablenkungstemperatur | Chemische Beständigkeit |

|---|---|---|

| PLA | 55 °C | Geringere Beständigkeit gegenüber Chemikalien und Lösungsmitteln |

| PETG | 70°C | Bessere Beständigkeit gegenüber Chemikalien, Ölen und UV-Strahlung |

| ABS | 98°C | Gute Beständigkeit gegenüber vielen Chemikalien und Lösungsmitteln |

| Nylon | N/A | N/A |

| Polycarbonat | N/A | N/A |

ABS bietet die höchste Wärmeformbeständigkeit der genannten Materialien und eignet sich daher für hitzeexponierte Bauteile. PETG ist chemikalienbeständiger als PLA und daher vorteilhaft für Anwendungen im Außenbereich oder in industriellen Umgebungen. PLA weist eine geringere Beständigkeit gegenüber Hitze und Chemikalien auf und ist daher am besten für Umgebungen mit geringer Belastung geeignet.

Schichthaftung

Die Schichthaftung beschreibt, wie gut die einzelnen Druckschichten miteinander verbunden sind. Eine gute Schichthaftung ist entscheidend für die Festigkeit und Haltbarkeit von 3D-gedruckten Teilen. Dünnere Schichten können die Festigkeit erhöhen, da das geschmolzene Material besser zwischen den Schichten haftet. Die Nähe der Düse zur vorherigen Schicht trägt zur Erwärmung des Materials bei und verbessert so die Haftung.

- Dünnere Schichten können die Festigkeit aufgrund einer besseren Verbindung zwischen den Schichten erhöhen.

- Das geschmolzene Material wird effektiver aus der Düse herausgepresst, wodurch die Haftung verbessert wird.

- Die Nähe der Düse zur vorherigen Schicht trägt zur Erwärmung des Materials bei und unterstützt so die Haftung zusätzlich.

Die Schichthaftung ist für die strukturelle Integrität Die Haltbarkeit von 3D-gedruckten Objekten hängt von der Qualität der Schichthaftung ab. Schwache Schichthaftung kann zu leicht zerbrechlichen oder verformbaren Drucken führen. Die Qualität der Schichthaftung beeinflusst direkt die Gesamtstabilität des gedruckten Teils.

- Eine mangelhafte Haftung der Schichten beeinträchtigt die strukturelle Integrität der Drucke, ähnlich wie bei einem Gebäude mit schwachem Fundament.

- Dies ist besonders wichtig für Funktionsteile, die eine höhere Haltbarkeit erfordern.

Kurzübersichtstabelle: Festigkeitsvergleich

Die folgende Tabelle bietet einen schnellen Vergleich der Festigkeitseigenschaften gängiger 3D-Druckmaterialien, einschließlich Zugfestigkeit, Schlagfestigkeit, Flexibilität und Temperaturbeständigkeit.

| Material | Zugfestigkeit (MPa) | Schlagfestigkeit | Flexibilität | Hitzebeständigkeit | Schichthaftung |

|---|---|---|---|---|---|

| PLA | 50-60 | Niedrig | Niedrig | Niedrig | Mäßig |

| PETG | 40-50 | Hoch | Mäßig | Mäßig | Gut |

| ABS | 34-36 | Hoch | Mäßig | Hoch | Gut |

| Nylon | 50-80 | Sehr hoch | Hoch | Mäßig | Gut |

| Polycarbonat | 60-70 | Hoch | Mäßig | Hoch | Gut |

| TPU | 25-35 | Sehr hoch | Sehr hoch | Mäßig | Gut |

| PAHT CF15 | 85-100 | Sehr hoch | Mäßig | Sehr hoch | Gut |

Dieser umfassende Vergleich hilft Anwendern bei der Auswahl des richtigen Materials anhand von Zugfestigkeit, Schlagfestigkeit, Flexibilität, Temperaturbeständigkeit und Schichthaftung. Sowohl robuste Polyjet-Materialien als auch hochfeste FDM-Filamente bieten spezifische Vorteile für unterschiedliche Anwendungen. Durch das Verständnis dieser Unterschiede können Anwender das optimale Filament für ihre Bedürfnisse auswählen und so die Langlebigkeit und Leistungsfähigkeit ihrer 3D-gedruckten Teile sicherstellen.

Druckeinstellungen und Teileausrichtung

Schichthöhe und Füllung

Schichthöhe und Füllparameter spielen eine wichtige Rolle für die Festigkeit von 3D-gedruckten Objekten.Durch Erhöhung des Füllgrades kann die Festigkeit eines Bauteils gesteigert werden. 10 MPa bei 10 % Füllung bis 46 MPa bei 100 % Füllung. Das bedeutet, dass eine höhere Füllung die Bauteile deutlich stabiler und steifer macht. Eine geringere Füllung führt zu leichteren Bauteilen mit einer gewissen Flexibilität, was sich gut für Prototypen eignet. Für Funktionsbauteile ist eine höhere Füllung notwendig, um maximale Festigkeit zu erreichen.

Die Schichthöhe beeinflusst auch die Festigkeit. Ein mit 0,1 mm Schichthöhe gedrucktes Bauteil erreicht eine maximale Spannung von 29 MPa. Bei einer Erhöhung der Schichthöhe auf 0,2 mm steigt die maximale Spannung auf 35 MPa, was einer Verbesserung von 21 % entspricht. Bei Schichthöhen über 0,2 mm bleibt die Festigkeit konstant bei etwa 36 MPa. Die Wahl der richtigen Kombination aus Schichthöhe und Füllung ermöglicht es dem Anwender, Gewicht, Druckzeit und Festigkeit optimal auszubalancieren.

Tipp: Für Teile, die eine hohe Festigkeit erfordern, verwenden Sie einen höheren Füllprozentsatz und eine Schichthöhe von mindestens 0,2 mm.

Drucktemperatur und Geschwindigkeit

Drucktemperatur Die Geschwindigkeitseinstellungen beeinflussen auch die Festigkeit von 3D-gedruckten Materialien. Jeder Filamenttyp hat einen idealen Temperatur- und Geschwindigkeitsbereich für optimale Ergebnisse. Die folgende Tabelle zeigt empfohlene Einstellungen für gängige Materialien:

| Material | Drucktemperatur (°C) | Druckgeschwindigkeit (mm/s) |

|---|---|---|

| PLA | 190-220 | 60-150 |

| PETG | 240-265 | ≤ 60 |

| ABS | 240-270 | 40-60 |

Das Drucken bei der richtigen Temperatur gewährleistet eine gute Schichthaftung und damit eine höhere Festigkeit. Langsamere Druckgeschwindigkeiten ermöglichen es dem Material, abzukühlen und sich optimal zu verbinden, wodurch das Bauteil stabiler wird. Ist die Temperatur zu niedrig oder die Geschwindigkeit zu hoch, haften die Schichten möglicherweise nicht gut, was die Festigkeit des fertigen Bauteils beeinträchtigt.

Orientierung und Schichtbindung

Die Ausrichtung der Bauteile während des Druckvorgangs hat einen großen Einfluss auf deren Festigkeit. FDM-Drucke weisen anisotrope Eigenschaften auf, d. h. die Festigkeit variiert je nach Richtung. Die Verbindungen zwischen den Schichten (Z-Achse) sind schwächer als die Verbindungen innerhalb der einzelnen Schichten (XY-Ebene). Für maximale Festigkeit sollten die Bauteile so ausgerichtet werden, dass die Hauptkräfte entlang der XY-Ebene wirken.

- Teile, die flach in einem Winkel von 45 Grad zur x-Achse gedruckt werden, können Folgendes bewältigen: bis zu 90 Pfund Kraft.

- Teile mit aufgedruckten Linien, die parallel zu den Kanten verlaufen, brechen bei einer Krafteinwirkung von weniger als 1 Pfund.

- Die Ausrichtung kritischer Kräfte parallel zur XY-Ebene erhöht die Festigkeit.

- Durch das Drucken eines Hakens an der Seite werden schwache Schichtlinien vermieden und die Leistung verbessert.

Eine gute Schichthaftung ist für stabile Bauteile unerlässlich. Die Ausrichtung eines Bauteils und die Art der Schichthaftung entscheiden darüber, ob das Bauteil Belastungen standhält oder leicht bricht.

Hinweis: Bei der Konstruktion für den 3D-Druck mit dem Ziel der Festigkeit sollten Sie stets die Bauteilausrichtung und die Schichthaftung berücksichtigen.

Auswahl von Materialien für mehr Festigkeit

Die Wahl des richtigen Materials für ein 3D-Druckprojekt hängt von der jeweiligen Anwendung und der benötigten Festigkeit ab. Anwender sollten bei ihrer Auswahl verschiedene Kriterien berücksichtigen.Die folgende Tabelle gibt einen Überblick wichtige Faktoren für die Festigkeitsoptimierung und Gesamtleistung:

| Kriterien | Beschreibung |

|---|---|

| Mechanische Festigkeit | Die Fähigkeit des Materials, Kräften standzuhalten, ohne zu brechen. |

| Flexibilität | Die Fähigkeit des Materials, sich zu biegen, ohne zu brechen, ist für bestimmte Anwendungen wichtig. |

| Chemische Beständigkeit | Die Fähigkeit des Materials, bei Einwirkung von Chemikalien einer Zersetzung zu widerstehen. |

| Hitzebeständigkeit | Die Fähigkeit des Materials, hohen Temperaturen standzuhalten, ohne sich zu verformen. |

| Oberflächenbeschaffenheit | Die Qualität der Oberflächenstruktur, die sich auf Ästhetik und Funktionalität auswirken kann. |

Funktionsteile

Funktionale Bauteile erfordern hohe Festigkeit und Haltbarkeit. Polycarbonat-, PETG- und Nylonfilamente eignen sich hervorragend für diese Anwendungen. Polycarbonat bietet eine ausgezeichnete Schlagfestigkeit und Zugfestigkeit. PETG bietet hohe Festigkeit und Haltbarkeit für den alltäglichen Druck. Nylon vereint gute Festigkeit mit Flexibilität und ist daher für bewegliche Teile geeignet. Für Bauteile in der anspruchsvollen Fertigung, PEI- und PEEK-Filamente bieten eine hohe mechanische und thermische Beständigkeit, was in Branchen wie der Automobil- und Elektronikindustrie von großer Bedeutung ist.

Pro Typisierung

Verwendung im Freien und bei hohen Temperaturen

Für Anwendungen im Außenbereich und bei hohen Temperaturen werden Materialien mit besonderen Eigenschaften benötigt. ASA zeichnet sich durch seine hervorragende UV- und Hitzebeständigkeit aus und ist daher eine Top-Wahl für Außenanwendungen. PETG und ABS eignen sich ebenfalls gut für den Außenbereich, ASA bietet jedoch die beste Kombination aus Festigkeit und Witterungsbeständigkeit. Die folgende Tabelle vergleicht gängige Filamente für den Außeneinsatz:

| Glühfaden | UV-Beständigkeit | Hitzebeständigkeit | Wasserbeständigkeit | Bewertung für den Außenbereich |

|---|---|---|---|---|

| ASA | Exzellent | Hoch | Gut | ★★★★★ |

| ABS | Arm | Hoch | Gerecht | ★★☆☆☆ |

| PLA | Sehr schlecht | Niedrig | Arm | ★☆☆☆☆ |

Die Wahl des richtigen Materials für den Außeneinsatz gewährleistet dauerhafte Leistungsfähigkeit und Zuverlässigkeit.

Balance zwischen Festigkeit und Druckbarkeit

Durch die Ausgewogenheit von Festigkeit und Druckbarkeit erzielen Anwender die besten Ergebnisse für ihre Projekte.Eine höhere Fülldichte und dickere Wände erhöhen die Festigkeit, verlängern aber auch die Druckzeit und erhöhen den Materialverbrauch. Geringere Schichthöhen verbessern die Haftung zwischen den Schichten, was die Festigkeit steigert. Langsamere Druckgeschwindigkeiten und sorgfältige Kühleinstellungen tragen zu einer starken Schichthaftung bei. Nachbearbeitungsverfahren wie das thermische Tempern können Festigkeit und Schlagfestigkeit weiter verbessern. Die Wahl des richtigen Materials und die Optimierung der Druckeinstellungen gewährleisten, dass die Bauteile sowohl die Anforderungen an Festigkeit als auch an Leistung erfüllen.

Tipp: Um die besten Ergebnisse zu erzielen, sollten die Materialeigenschaften stets den Anforderungen der Anwendung entsprechen.

Die Auswahl des richtigen 3D-Druckmaterials erfordert ein Verständnis der jeweiligen Eigenschaften der einzelnen Optionen. Jüngste Studien zeigen, dass PLA eignet sich gut für Prototypen., ABS bietet Langlebigkeit, PETG ermöglicht die Herstellung leichter, hochfester Bauteile. Nylon- und Kohlefaserfilamente gewährleisten eine lange Lebensdauer. Anwender sollten mit verschiedenen Materialien und Einstellungen experimentieren, um die optimale Lösung für ihre Projekte zu finden. Die Erforschung fortschrittlicher Kombinationen und Drucktechniken kann zu besten Ergebnissen führen.

- Für weiterführende Informationen können fortgeschrittene Anwender Verbundfilamente und Spezialharze erforschen.

- beides verstehen Materialeigenschaften und Druckparameter führt zu stärkeren, zuverlässigeren Ausdrucken.

Häufig gestellte Fragen

Welches ist das widerstandsfähigste 3D-Druckmaterial für den täglichen Gebrauch?

Polycarbonat zählt zu den robustesten gängigen 3D-Druckmaterialien. Es bietet hohe Schlagfestigkeit und Langlebigkeit. Viele Anwender wählen es für Funktionsteile, die Belastungen standhalten müssen. Polycarbonat eignet sich sowohl für private als auch für industrielle 3D-Druckprojekte.

Sind 3D-Druckmaterialien für den Außenbereich geeignet?

Einige 3D-Druckmaterialien wie ASA und PETG sind UV- und feuchtigkeitsbeständig und eignen sich daher gut für den Außeneinsatz. PLA hingegen ist im Außenbereich nicht lange haltbar, da es durch Sonnenlicht und Regen zersetzt wird. Anwender sollten die Materialien daher je nach Umgebungsbedingungen auswählen.

Warum beeinflusst die Bauteilausrichtung die Festigkeit beim 3D-Druck?

Die Ausrichtung des Bauteils beeinflusst die Schichthaftung beim 3D-Druck. In bestimmten Richtungen haften die Schichten besser aneinander. Dies wirkt sich auf die endgültige Festigkeit des Materials aus. Das Drucken von Bauteilen mit der Hauptkraft entlang der XY-Ebene erhöht die Haltbarkeit.

Wie beeinflusst der Füllgrad die Festigkeit von 3D-gedruckten Materialien?

Ein höherer Füllgrad macht 3D-gedruckte Materialien fester und steifer. Ein geringerer Füllgrad führt zu leichteren Teilen, verringert aber deren Festigkeit. Anwender sollten den Füllgrad an den Verwendungszweck des Bauteils anpassen. Funktionale Teile benötigen einen höheren Füllgrad für eine bessere Leistung.

Sind Metallfilamente für den 3D-Druck besser geeignet als Kunststoffmaterialien?

Metallfilamente, wie beispielsweise Aluminium, bieten eine höhere Festigkeit als die meisten Kunststoffe. Sie sind teurer und erfordern spezielle 3D-Druckausrüstung. Für die meisten Projekte robuste Kunststoffe wie Polycarbonat oder Nylon bieten ein gutes Gleichgewicht zwischen Festigkeit und Bedruckbarkeit.