Optimizing your Sovol SV08 Max printer unlocks impressive print speed and quality. You achieve consistent results by using features such as auto-leveling and regular calibration on your 3d printing setup. Always check your printer before each printing job. Focus on proper setup, calibration, and maintenance to keep your Sovol SV08 Max performing at its best. Apply these tips step-by-step to elevate your 3d printing experience and ensure every print meets your expectations for quality.

Key Takeaways

- Always start with auto-bed leveling to ensure a perfect first layer. This step prevents failed prints and saves time.

- Regularly calibrate your extruder and adjust E-steps to maintain precise filament flow. This practice enhances print quality and layer adhesion.

- Choose the right filament type for your project. Proper selection leads to better results and fewer printing issues.

- Optimize slicer settings like layer height and wall thickness to control detail and strength. Adjust these settings based on your project needs.

- Keep your printer well-maintained with regular cleaning and firmware updates. This habit extends the life of your Sovol SV08 Max and ensures consistent performance.

Sovol SV08 Max Setup Essentials

Auto-leveling for a perfect first layer

You want every print on your Sovol SV08 Max to start with a flawless first layer. Begin each session by running the auto-bed leveling feature. This process uses sensors to measure the bed surface and adjust the nozzle height. You should always check the results of bed leveling before starting a new print. If you notice any unevenness, repeat the leveling process. Consistent leveling ensures that your 3d printing projects stick well to the bed and reduces the risk of failed prints.

Tip: Make auto-bed leveling part of your regular routine. This habit saves time and prevents common printing issues.

Nozzle and bed checks

Before you start printing, inspect the nozzle and bed. A clean nozzle allows for smooth filament flow. Remove any debris or old filament from the tip. Examine the bed for scratches or residue. Wipe the surface with isopropyl alcohol to improve adhesion. You should also verify that the bed remains flat after each leveling cycle. If you see any warping, address it before printing. These checks help maintain the quality of your Sovol SV08 Max prints.

Frame stability and linear rail upgrades

A stable frame supports high-speed 3d printing and sharp details. Tighten all bolts and check for any wobble in your Sovol SV08 Max printer. Upgrading to linear rails can further improve stability and accuracy. Linear rails guide the print head smoothly, reducing vibrations during fast movements. This upgrade, combined with precise bed leveling, leads to better print quality and fewer errors. You will notice cleaner lines and more reliable results in your printing projects.

Note: Regularly inspect your printer’s frame and rails. Early detection of loose parts or wear keeps your Sovol SV08 Max running smoothly.

Calibration for Advanced 3D Printing

Extruder and E-steps tuning

You achieve precise filament flow by performing extruder calibration on your Sovol SV08 Max. Start by measuring the actual filament extruded compared to the commanded amount. Adjust the E-steps value in your printer’s firmware until the output matches your input. This process prevents under-extrusion and over-extrusion, which can affect print quality and cause weak or messy layers. Repeat extruder calibration regularly, especially after changing the extruder or using new filament. Consistent calibration ensures your 3d printing projects maintain sharp details and strong layer adhesion.

PID tuning and input shaping

You boost print quality and speed on your Sovol SV08 Max by mastering PID tuning and input shaping. PID tuning analyzes heating and cooling cycles, allowing your printer to maintain the target temperature. Stable temperatures lead to smoother extrusion and fewer printing defects. Input shaping compensates for vibrations in the print head and adjusts accelerations. You can print faster without sacrificing quality.

- PID tuning keeps the hotend temperature steady, improving layer consistency.

- Input shaping reduces ringing and ghosting, even at high speeds.

- Both features work together to enhance advanced 3d printing results.

Tip: Run PID tuning after replacing the hotend or heater cartridge. Activate input shaping if you notice vibrations or artifacts in your prints.

Z-offset and first layer adjustments

You set the foundation for every print by dialing in the Z-offset. Adjust the nozzle height so the filament lays flat and sticks well to the bed. Use a calibration print to test the first layer. If the filament squishes too much or barely touches the bed, fine-tune the Z-offset in your printer’s settings. Proper first layer adjustments prevent warping and improve adhesion. You should check the Z-offset after changing the build surface or nozzle. Reliable first layers lead to higher print quality and fewer failed printing jobs on your Sovol SV08 Max.

Filament and Material Tips

Choosing and storing filament

Selecting the right filament for your Sovol SV08 Max printer sets the stage for high-quality prints. You should match the filament type to your project’s needs. PLA works well for most users who want sharp details and smooth layers. ABS offers strength and durability, making it ideal for functional parts that require high resolution. PETG combines flexibility and toughness, while TPU provides flexibility for specialized prints. Always store filament in a dry, sealed container. Moisture can cause bubbles and reduce print quality. Use silica gel packs to keep your filament dry and ready for 3d printing. Proper storage ensures your printer delivers sharp details and smooth layers every time.

Temperature settings for quality and speed

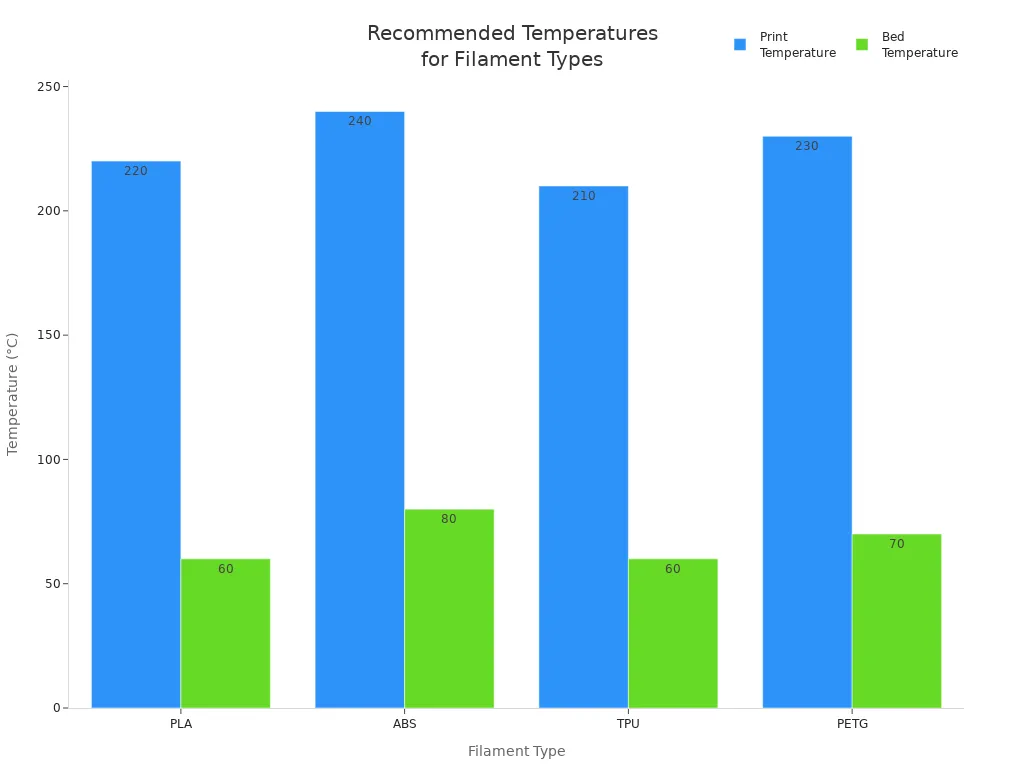

Dialing in the correct temperature settings on your Sovol SV08 Max printer leads to sharp details and smooth layers. Each filament type requires specific temperatures for optimal print quality and speed. Refer to the table below for recommended settings:

|

Filament Type |

Print Temperature |

Bed Temperature |

|---|---|---|

|

PLA |

220 °C |

60 °C |

|

ABS |

240 °C |

80 °C |

|

TPU |

210 °C |

60 °C |

|

PETG |

230 °C |

70 °C |

You achieve high resolution and sharp details by following these tips. Adjust the print temperature if you notice stringing or poor adhesion. Fine-tuning these settings on your printer helps you maintain consistent print quality and sharp details across all your 3d printing projects.

Multi-color printing options

You can unlock creative possibilities on your Sovol SV08 Max by exploring multi-color printing. Use a multi-material upgrade or filament swaps to add sharp details and vibrant colors to your models. Plan your color changes at specific layers for the best resolution and smooth layers. Multi-color prints showcase the full capabilities of your printer and highlight sharp details in every design. These tips help you achieve professional results and make your 3d printing projects stand out.

Slicer Settings Tips

Layer height and wall thickness

You control the detail and strength of your prints by adjusting layer height and wall thickness in your slicer. For the Sovol SV08 Max, start with a layer height between 0.16 mm and 0.24 mm for most projects. Lower layer heights give you smoother surfaces and higher resolution, while thicker layers print faster but may show more visible lines. Wall thickness affects the durability of your models. Set wall thickness to at least 1.2 mm or three times your nozzle diameter. This setting helps your printer produce strong, reliable parts.

When you use the recommended settings for layer height and wall thickness, you improve both speed and quality. If you print functional parts, increase wall thickness for extra strength. For display models, choose a finer layer height to highlight details. Always match these settings to your filament type and project needs. You will see better results and fewer print failures.

Tip: Print a small test cube with different layer heights and wall thicknesses. Compare the results to find the best balance for your Sovol SV08 Max.

Print speed and acceleration

You can boost your 3d printing efficiency by fine-tuning print speed and acceleration. The Sovol SV08 Max supports high-speed printing, but you must balance speed with quality. Start with a print speed of 60–80 mm/s for standard filaments like PLA and PETG. For more demanding materials, reduce the speed to maintain detail and adhesion. Acceleration settings control how quickly your printer changes direction. High acceleration can cause ringing or ghosting, especially on large prints.

Use the recommended settings from your slicer as a baseline. Gradually increase speed and acceleration while monitoring print quality. If you notice defects, lower the values until you achieve smooth surfaces and sharp edges. The Sovol SV08 Max handles higher speeds well when you combine stable frame upgrades and proper calibration.

Note: Fast printing saves time, but always check for signs of vibration or layer misalignment. Adjust acceleration to match your printer’s stability and the type of filament you use.

Retraction, cooling, and supports

You achieve clean, precise prints on your Sovol SV08 Max by optimizing retraction, cooling, and support settings. These slicer options directly affect the surface finish and structural integrity of your models.

- Retraction settings prevent stringing and blobs by pulling the filament back during travel moves. Set retraction distance and speed based on your filament type. For PLA, start with a retraction distance of 4–6 mm and a speed of 40–60 mm/s.

- Cooling fans solidify each layer quickly, improving overhangs and reducing warping. Enable part cooling for PLA and PETG, but lower the fan speed for ABS to avoid cracks.

- Support structures allow you to print complex shapes and bridges. Use the recommended settings for support density and pattern. Proper supports ensure your printer maintains high precision and quality, especially on challenging models.

A good slicer optimizes these features to deliver the best results. Poorly tuned retraction, cooling, or supports can lead to rough surfaces, visible layer lines, or weak spots in your prints. Always test new settings with small models before starting large projects.

Tip: Review your slicer’s preview mode to check support placement and retraction paths. Adjust settings as needed to minimize cleanup and improve print quality.

Advanced Features for Sovol SV08 Max

Klipper and firmware upgrades

You can unlock new capabilities on your Sovol SV08 Max by upgrading the printer firmware to Klipper. Klipper gives you advanced control over your 3d printing process. You gain access to faster print speeds and improved quality. The Sovol SV08 Max supports Klipper, which allows you to fine-tune settings and automate tasks. You should always back up your printer’s current firmware before starting any upgrade. Follow the manufacturer’s instructions to avoid errors. After installing Klipper, you can adjust parameters that affect filament flow and print accuracy. Many users report smoother surfaces and sharper details after upgrading.

Tip: Update your firmware regularly to benefit from new features and bug fixes. This habit keeps your printer running efficiently and ensures consistent quality.

Input shaping and pressure advance

You can reduce vibrations and improve print quality by enabling input shaping on your Sovol SV08 Max. Input shaping analyzes the printer’s movements and compensates for mechanical limitations. You see fewer artifacts and cleaner lines in your 3d printing projects. Pressure advance helps you control filament flow during fast direction changes. This feature prevents blobs and gaps, especially when printing at high speeds. You should calibrate pressure advance for each filament type you use. Proper calibration leads to smoother layers and better adhesion.

- Input shaping minimizes ringing and ghosting.

- Pressure advance optimizes extrusion for sharp corners and fine details.

Custom macros for efficiency

You can streamline your 3d printing workflow by creating custom macros on your Sovol SV08 Max. Macros automate repetitive tasks, such as filament changes or bed leveling. You save time and reduce mistakes by using these shortcuts. Many printer owners write macros for preheating, nozzle cleaning, and filament loading. You can store macros in your firmware and activate them with a single command. Custom macros help you maintain print quality and keep your printer ready for every project.

Note: Test each macro with a simple print before using it on complex models. This practice ensures reliability and protects your Sovol SV08 Max from unexpected issues.

Maintenance and Care Tips

Cleaning and lubrication routines

You keep your Sovol SV08 Max running smoothly by following a regular cleaning and lubrication schedule. Dust and leftover filament can build up on your printer’s moving parts. Wipe down the rails, bed, and extruder with a lint-free cloth after every few prints. Remove any filament debris from the nozzle and gears. Apply a small amount of lubricant to the linear rails and lead screws. This step reduces friction and helps your printer move with precision. Clean parts ensure your 3d printing projects maintain high quality and prevent unexpected failures.

Tip: Schedule a deep cleaning every month. This habit extends the life of your Sovol SV08 Max and keeps your prints looking sharp.

Firmware updates and backups

You improve your printer’s performance and reliability by keeping the firmware up to date. Check for new firmware releases from Sovol regularly. Updates often include bug fixes and new features that boost print quality and speed. Before you update, always back up your current settings. Save your configuration files to a safe location. This backup lets you restore your Sovol SV08 Max if you encounter problems during the update. Updated firmware helps your printer handle new filament types and advanced 3d printing techniques.

Inspecting belts and moving parts

You protect your Sovol SV08 Max from wear by inspecting belts and moving parts often. Loose or worn belts can cause layer shifting and reduce print quality. Check the tension of each belt before starting a new printing job. Tighten or replace belts if you notice slack or fraying. Examine pulleys, wheels, and bearings for signs of damage. Replace any worn parts to keep your printer running at peak performance. Regular inspections help you avoid print failures and maintain consistent results with every filament you use.

- Inspect belts for tension and wear.

- Check pulleys and bearings for smooth movement.

- Replace damaged parts to ensure high-quality 3d printing.

Note: A well-maintained Sovol SV08 Max delivers reliable printing and extends the life of your printer.

Troubleshooting Print Quality

Diagnosing common issues

You may encounter several common problems when using your Sovol SV08 Max. Diagnosing these issues quickly helps you maintain high print quality and avoid wasted time or filament. Start by checking your printer’s display for error messages. Examine your first layer closely. If you see poor adhesion, uneven lines, or gaps, you should review your bed leveling and Z-offset settings. Warping or curling often points to incorrect bed temperature or insufficient adhesion.

Use this checklist to diagnose frequent 3d printing issues:

- Under-extrusion: Check for clogged nozzles, low print temperature, or incorrect E-steps.

- Over-extrusion: Inspect filament diameter settings and reduce flow rate if needed.

- Layer shifting: Tighten belts and check for obstructions on the rails.

- Stringing or blobs: Adjust retraction distance and speed in your slicer.

- Poor surface finish: Clean the nozzle and ensure the cooling fan works properly.

Tip: Keep a log of your troubleshooting print quality steps. This habit helps you identify patterns and resolve recurring problems faster.

Speed-related print failures

High-speed printing can push your Sovol SV08 Max to its limits. If you notice defects at faster speeds, you need to adjust your settings to balance speed and quality. Common speed-related failures include ringing, ghosting, and layer misalignment. These problems often result from excessive acceleration or unstable frame components.

Follow these tips to address speed-related print failures:

- Lower your print speed in small increments. Observe the results after each change.

- Reduce acceleration and jerk settings in your slicer. This adjustment minimizes vibrations.

- Inspect your printer’s frame and tighten all bolts. A stable frame supports higher speeds.

- Enable input shaping and pressure advance features if your firmware supports them. These tools help control vibrations and improve print quality.

- Use high-quality filament. Poor filament can worsen issues at high speeds.

A table can help you track adjustments and their effects:

|

Setting Changed |

Before |

After |

Result |

|---|---|---|---|

|

Print Speed (mm/s) |

100 |

80 |

Less ringing |

|

Acceleration (mm/s²) |

3000 |

2000 |

Improved layer lines |

|

Jerk (mm/s) |

10 |

7 |

Reduced ghosting |

Support removal and surface finishing

Removing supports cleanly and finishing your prints can elevate the final appearance of your 3d printing projects. The Sovol SV08 Max produces strong supports, but you must remove them carefully to avoid damaging your model. Wait until the print cools before removing supports. Use pliers or a scraper for stubborn areas. For delicate models, try dissolvable supports if your printer and filament support them.

After support removal, you can improve surface quality with simple finishing techniques:

- Sand rough areas with fine-grit sandpaper.

- Use a hobby knife to trim small imperfections.

- Apply a heat gun briefly to smooth minor surface flaws.

- For PLA prints, consider a light polish with a plastic-safe compound.

Tip: Always wear safety glasses when removing supports or sanding. Protect your eyes from flying debris.

You can achieve professional results by combining careful support removal with proper finishing. These steps ensure your Sovol SV08 Max delivers the best possible print quality for every project.

You can boost print speed and quality on your sovol sv08 max by focusing on setup, calibration, slicer settings, and regular maintenance. Gradually apply improvements and track your results for the best outcomes. Key factors for success include:

- Calibrating print speed and mechanics for accuracy

- Upgrading to Klipper firmware for faster, error-free prints

- Choosing high-quality materials to reduce errors

- Adjusting movement speed, layer height, and line width for optimal duration

Leverage advanced features and troubleshooting to achieve professional results with every print.

FAQ

How often should you calibrate your Sovol SV08 Max?

You should calibrate your Sovol SV08 Max every few weeks or after any hardware change. Regular calibration ensures consistent print quality and prevents common issues like layer shifting or poor adhesion.

What is the best way to prevent filament jams?

Keep your nozzle clean and use high-quality filament. Store filament in a dry container with silica gel packs. Check for proper extruder tension. These steps help you avoid jams and maintain smooth extrusion.

Can you use third-party firmware on the Sovol SV08 Max?

Yes, you can install third-party firmware like Klipper or Marlin. Always follow official guides and back up your settings before upgrading. Third-party firmware unlocks advanced features and improves print performance.

Why does your first layer not stick to the bed?

Check your bed leveling and Z-offset. Clean the bed with isopropyl alcohol. Use the correct bed temperature for your filament. These actions help your prints adhere properly and reduce the risk of warping.

How do you reduce ringing or ghosting at high speeds?

Enable input shaping and pressure advance in your firmware. Tighten the printer frame and check belt tension. Lower acceleration settings if needed. These adjustments minimize vibrations and improve surface quality.