You can learn 3d printing with just a few simple steps. If you wonder how to start using a 3d printer as a beginner, you’re not alone. Mistakes happen, and that’s okay. Most people succeed early—

69% of first-time users complete a print.

You can build confidence with practice.

3D Printing Basics

How It Works

You may wonder what a 3d printer does inside. First, you need a digital model. You send this model to your 3d printer. The printer builds the object one layer at a time. Most beginners use Fused Deposition Modeling (FDM). The printer melts plastic filament and puts it down in thin lines. Some printers use lasers or light to shape metal or resin.

Here’s a quick look at different 3d printing methods:

|

Description |

|

|---|---|

|

Fused Deposition Modeling (FDM) |

Pushes melted plastic to make layers. |

|

Stereolithography (SLA) |

Uses UV light to harden liquid resin. |

|

Selective Laser Sintering (SLS) |

A laser heats powder to make solid shapes. |

|

Selective Laser Melting (SLM) |

A laser melts metal powder to join it. |

|

Direct Metal Laser Sintering (DMLS) |

A laser joins metal powders together. |

3d printing adds material instead of cutting it away. This lets you make shapes that are hard to create with other tools.

What to Expect

When you start using a 3d printer, you can design and make things for yourself. You can print test models to try out ideas fast. You can make objects for your home or hobbies. Some people use 3d printing for parts or small products.

Tip: You do not need to be an expert to begin. Many people print easy things first, like keychains or phone stands.

3d printing takes time, especially for big items. The printer works slowly and builds each layer carefully. Your first print may finish in a few hours. Watching your 3d printer work is fun. It feels great to see your idea become real.

Choosing a 3D Printer

Types for Beginners

Picking your first 3d printer can feel overwhelming, but you can make it simple by following a few steps:

- Think about why you want a 3d printer. Do you want to use it for hobbies, school, or maybe a small business?

- Decide what you want to print. If you plan to make toys, gadgets, or parts, an FDM 3d printer is a great choice. If you want to print miniatures or jewelry, a resin (SLA) printer works better.

- Check the size of the things you want to print. Some printers can only make small objects, while others handle bigger projects.

- Set your budget. Remember, you will spend money on materials and maintenance, not just the printer.

Here are two popular brands for entry-level 3d printers:

|

Brand |

Market Share (%) |

Year-over-Year Growth (%) |

|---|---|---|

|

47 |

64 |

|

|

Bambu Lab |

26 |

336 |

You will find many helpful guides and videos for these brands, which makes learning 3d printing easier.

Materials

You need to pick the right material for your 3d printing projects. Most beginners use PLA filament. It is easy to print, safe, and comes in many colors. If you want stronger parts, try PETG or ABS. For resin printers, you use liquid resin, which gives you smooth and detailed prints.

- PLA: Good for most projects and easy to use.

- PETG: Stronger and a bit flexible.

- ABS: Tough but needs good ventilation.

- Resin: Best for tiny, detailed models.

Choosing the right 3d printer and material helps you get the best results and enjoy your 3d printing journey.

3D Printer Setup

Getting your 3d printer ready is very important. You need to make sure it is safe and strong before you print. There are three main steps: assembly, bed leveling, and calibration.

Assembly

Opening your new 3d printer box is exciting. Before you begin, get all your tools and materials together. You should have glue, sandpaper, cutters, clamps, and safety gear close by. Here are some safety tips:

- Wear gloves and glasses when sanding or using glue.

- Clean dust and grease with alcohol and a lint-free cloth.

- Look at parts for problems. Cut rough edges with a sharp knife.

- Keep a fire extinguisher and alarm in your workspace.

- Turn on thermal runaway protection in your printer’s software.

- Use good parts to lower the chance of electrical fires.

- Check your 3d printer often for damage.

Put your 3d printer on a flat, strong table. This stops shaking and helps your prints come out right. If you have a digital caliper, use it to measure parts and check the fit. Tweezers, pliers, and print removal tools help with small jobs. A filament dryer and good storage keep your filament in good shape.

Tip: A 3d printer enclosure keeps the temperature steady and stops dust from getting on your prints.

Bed Leveling

Bed leveling helps you get great 3d prints. If the bed is not level, the first layer may not stick. Your print could fail. The nozzle should be the same distance from the bed everywhere.

Here’s why bed leveling is important:

|

Impact Area |

Description |

|---|---|

|

Surface finish |

A level bed gives you smooth, even surfaces. |

|

Dimensional accuracy |

Calibration helps your prints match the size you want. |

|

Layer adhesion |

Good leveling makes layers stick together better. |

|

Preventing failures |

Proper leveling stops jams and warping before they start. |

Use a piece of paper or a feeler gauge to check the gap between the nozzle and the bed. Some printers have auto-leveling, but checking by hand is still good. Take your time with this step. It really helps your 3d printing work well.

Calibration

Calibration helps your 3d printer make strong and accurate prints. Run calibration tutorials and print test objects before big projects. Two common test prints are calibration cubes and thermal towers.

|

Test Object |

Purpose and Benefits |

|---|---|

|

Calibration Cube |

Checks size accuracy on all sides. Helps you find errors and misalignment. |

|

Thermal Tower |

Finds the best temperature for your filament. Shows problems like stringing and warping. |

Use a vernier caliper to measure your calibration cube. If the size is wrong, change your printer settings. The thermal tower helps you pick the right temperature for your filament. This makes layers stick better and surfaces look nicer.

Common calibration mistakes include first layer sticking problems, wrong sizes, and loose parts. If your first layer does not stick, your print may fail. If the size is off, check for heat or extrusion problems. Loose rails or belts can also make prints less accurate.

Note: Always print a calibration cube and a thermal tower before starting a new project or changing filament.

Now you are ready for your first 3d print. Careful setup helps you get a smooth and successful print.

Preparing to Print

Finding Models

You might feel excited to start your first 3d printing project. The good news is you do not have to design everything from scratch. Many websites offer free 3d print models that you can use with your 3d printer. Here are two great places to find beginner-friendly 3d print models:

- Thingiverse: You can browse thousands of free 3d print models. The site also has guides and tips for new users.

- Shapeways: This site gives you tutorials on 3d modeling software. You can learn how to change or create your own 3d print models.

You can download a model, then get ready to use your 3d printer.

Slicing Software

Before you start 3d printing, you need slicing software. This tool turns your 3d print models into instructions for your 3d printer. You will find several easy options for beginners. Here is a quick look:

|

Software |

Key Features |

Best For |

|---|---|---|

|

Open-source, works with many 3d printers, easy print profiles |

Beginners and enthusiasts |

|

|

PrusaSlicer |

Simple and advanced modes, good for Prusa 3d printers |

Prusa printer users |

|

Bambu Studio |

Clean interface, made for Bambu Lab 3d printers |

Bambu Lab printer users |

Pick the software that matches your 3d printer. You can follow setup guides to get started.

Print Settings

You control how your 3d printer works by changing print settings in your slicer. Two important settings are layer height and print speed. These affect how your 3d printing project looks and feels.

|

Aspect |

Thinner Layers (e.g., 0.1 mm) |

Thicker Layers (e.g., 0.3 mm) |

|---|---|---|

|

Print Quality |

Higher resolution, finer details |

More visible layer lines |

|

Print Speed |

Slower due to more layers |

Faster due to fewer layers |

|

Aesthetic Quality |

Smoother finish, less stepping |

Rougher finish, more stepping |

|

Strength |

Often stronger due to better bonding |

Weaker bonding possible |

|

Ideal Use Case |

High detail, polished finish |

Straight lines, flat surfaces |

Tip: Always watch the first layer when you start 3d printing. A good first layer helps your 3d print models stick to the bed and finish well.

You can try different settings to see what works best for your 3d printer and your 3d printing projects.

3D Printing Process

Starting a Print

You’re ready to see your idea come to life with your 3d printer. Before you hit start, follow these steps to help your 3d printing project succeed:

- Pick the right filament. Choose a material that matches your needs. PLA works well for most beginners, but you might want something stronger or more flexible.

- Check your 3d printer. Make sure the bed is level and the nozzle is clean. This helps your first layer stick and keeps your print smooth.

- Prepare the print bed. Wipe the surface so it’s free of dust and grease. A clean bed helps with print adhesion.

- Slice your model. Use slicing software to turn your design into instructions for your 3d printer. Adjust settings for the best results.

- Start the print. Watch the first layer closely. If it doesn’t stick, pause and fix it. The first layer sets the stage for the whole print.

Tip: Keep your workspace at a steady temperature. Sudden changes can cause warping or cracks, especially with resin 3d printing. Stable temperatures help your prints look better and last longer.

Monitoring

Once your 3d printing job begins, you need to keep an eye on it. Problems can pop up fast, especially in the first few layers. Here are ways to monitor your 3d printer:

- Watch the print in real time. You can spot issues like warping or gaps early.

- Use remote monitoring tools. Some printers let you check progress from your phone or computer.

- Set up alerts. Get notifications if something goes wrong.

- Prepare tools for quick fixes. Tweezers, spatulas, and pliers help you handle jams or loose filament.

|

Monitoring Method |

Description |

|---|---|

|

Cameras check each layer for defects like warping or gaps. |

|

|

Automated Defect Detection |

AI spots changes in shape or texture and alerts you right away. |

|

Remote Monitoring |

Track your 3d printer from anywhere, so you don’t have to stand by it. |

|

Performance Analytics |

Use data to improve settings and plan maintenance for better 3d printing. |

You don’t need to watch every minute, but checking often helps you catch problems before they ruin your 3d printing project.

Troubleshooting

Bed Adhesion

You might notice your prints peeling off or curling at the edges. That’s a sign of poor adhesion. Good adhesion keeps your 3d printing project stuck to the bed from start to finish. You can boost adhesion with a few simple tricks:

- Use glue sticks, hairspray, or special products for better adhesion.

- Pick the right build surface. Glass, PEI, or magnetic sheets help with adhesion.

- Adjust the Z-offset. This sets the nozzle at the perfect height for adhesion.

- Clean the build plate often. Dust and grease ruin adhesion.

- Change the bed temperature to match your filament. This improves adhesion.

Improving adhesion is key for every 3d printer user. If you want strong adhesion, always check your bed before you print. Adhesion problems can ruin your 3d printing project, so don’t skip these steps.

Extrusion Issues

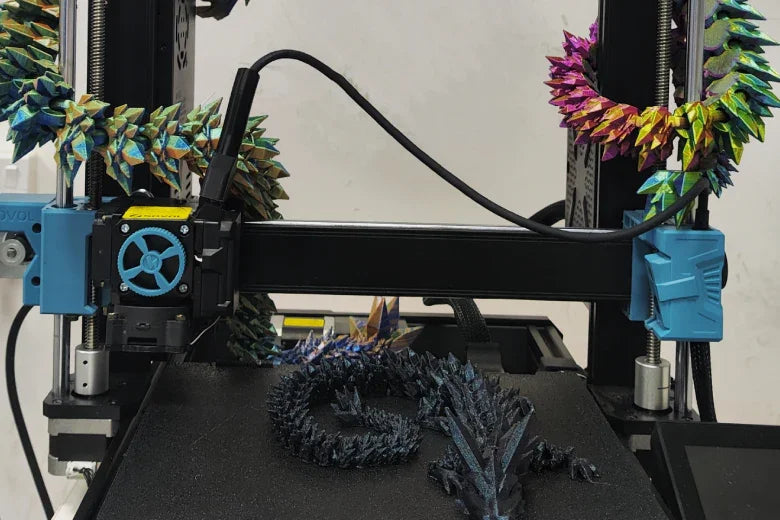

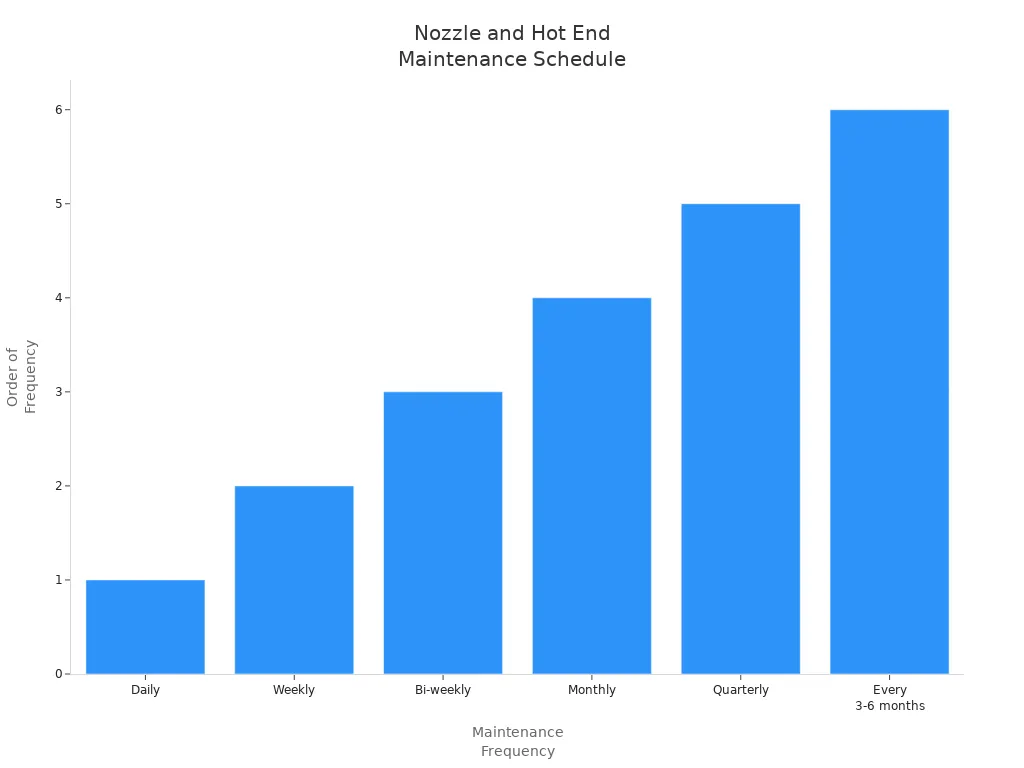

Sometimes your 3d printer stops pushing out filament or leaves gaps. These extrusion problems can mess up adhesion and print quality. You should clean the nozzle and hot end often. Here’s a chart to help you remember when to do it:

Check the nozzle daily for buildup. Clean the print bed weekly. Do a cold pull every two weeks. Soak the nozzle monthly if needed. Take apart the hot end every few months. Replace the nozzle if it gets worn. These steps keep extrusion smooth and help with adhesion.

Here’s a table with common issues and solutions:

|

Issue |

Description and Solution |

|---|---|

|

Under Extrusion |

Filament too cool for adhesion. Check for clogs and raise hotend temperature. |

|

Stops Extruding Mid Print |

Out of filament, clogged extruder, or overheated motor. Fix these for better adhesion. |

|

Inconsistent Extrusion |

Filament problems or wrong settings. Adjust for steady adhesion. |

Layer Problems

Layer shifting or rough surfaces can happen if your 3d printer shakes or parts get loose. These problems affect adhesion between layers. You can fix layer issues by checking mechanical parts:

- Tighten timing belts. This keeps layers lined up and helps adhesion.

- Secure the print bed and frame. Loose screws cause wobbling and poor adhesion.

- Place your 3d printer on a solid, level table. This reduces vibrations and improves adhesion.

If you want smooth 3d printing results, inspect moving parts often. Good adhesion between layers makes your prints strong and neat.

3D Printer Maintenance

Cleaning

Keeping your 3d printer clean helps you get better prints and fewer problems. Dust and leftover filament can build up fast. You should clean the nozzle and print bed often. Heat the nozzle to the last filament’s temperature to soften any stuck material. Use a brass brush to wipe the outside. If the nozzle gets blocked, try a thin needle to clear it. For the print bed, grab some isopropyl alcohol and a soft cloth. Wipe away dust and oils before every print.

Tip: A clean build plate helps your 3d printing projects stick better and finish smoother.

Regular cleaning does more than just make things look nice. It keeps your 3d printer running well and stops clogs or jams before they start. You save time and money by avoiding failed prints and wasted material.

|

Impact Area |

Description |

|---|---|

|

Print Quality |

Cleaning gives you smoother, more accurate prints. |

|

Preventing Hardware Failures |

Stops clogs and blockages that can break your printer. |

|

Long-Term Cost Savings |

Less waste and fewer repairs save you money over time. |

Regular Checks

You want your 3d printing experience to stay smooth. That means checking your machine often. Look at cables for any wear or loose spots. Make sure belts feel snug but not too tight. If you see any bent or damaged parts, fix them right away. Clean the rails and bearings so everything moves easily.

Here’s a quick checklist to keep your 3d printer in top shape:

- Inspect cables and connectors for damage.

- Check belt tension and adjust if needed.

- Clean the build plate before each print.

- Lubricate moving parts to reduce friction.

- Update firmware when new versions come out.

|

Component |

What to Check or Do |

|---|---|

|

Cables |

Look for fraying or loose connections. |

|

Deformed Parts |

Watch for warping, especially near the extruder. |

|

Belt Tension |

Make sure belts are not too loose or tight. |

|

Firmware Updates |

Install updates and back up your settings. |

|

Build Plate |

Clean before every print for best adhesion. |

If you follow these steps, your 3d printer will last longer and your 3d printing projects will turn out better.

You can achieve a great first print by following these steps:

- Set your nozzle height for a solid first layer.

- Clean your print bed with isopropyl alcohol.

- Adjust bed temperature for your material.

Keep experimenting with 3d printing. Try new projects, use CAD tools, and explore classroom kits.

Pro Tip: The 45-degree rule helps you get stronger prints with your 3d printer.

FAQ

What should I do if my print keeps peeling off the bed?

Try cleaning the bed, leveling it again, or using glue stick. A clean, level bed helps your print stick better.

Why is the filament not flowing from my 3D printer?

Check if the nozzle is clogged or the filament is tangled. Heat the nozzle and gently push the filament to clear any blockages.

Can I leave my 3D printer running overnight?

You should not leave your 3D printer unattended. Problems can happen fast. Always watch the first few layers and check on your print often.