Many people want to save money on 3D printing projects. He or she often sees the cost of 3D printing add up quickly, whether for small models or large parts.

- The average cost of 3D printing projects ranges from $1 for small objects to thousands for commercial work.

- The cost per hour for 3D printing services usually falls between $1 and $3. Practical tips can help lower the cost of 3D printing without lowering quality. Case studies show that smart choices can reduce expenses by up to 75%, making 3D printing more affordable for hobbyists and professionals.

Key Takeaways

- Choose cost-effective filaments like PLA and ABS to save money while maintaining quality in your 3D prints.

- Utilize recycled or budget materials for non-critical parts to significantly lower costs, but be aware of potential quality trade-offs.

- Optimize your 3D printing settings, such as layer height and infill density, to reduce material waste and energy use.

Materials to Lower 3D Printing Cost

Choose Cost-Effective Filaments

Selecting the right filament plays a major role in controlling the cost of 3d printing. He or she should compare filament types and prices to find the best value for each project. PLA and ABS often serve as cost-effective options for most hobbyists and professionals. These filaments offer reliable performance at a lower cost than specialty materials.

A simple table can help users see the price differences between popular 3d printing materials:

|

Product Type |

Price |

|---|---|

|

NylonX Carbon Fiber PA12 Filament (3kg) |

$362.00 ($339.37 in bulk) |

|

NinjaTek Cheetah Midnight Black TPU (2kg) |

$192.88 |

|

Black NylonG Glass Fiber Filament (3kg) |

$329.00 |

He or she should also consider the mechanical requirements of the print. FDM filaments like PLA and ABS work well for general use, while specialty filaments such as carbon fiber or flexible TPU cost more. Choosing the right filament for the job improves cost-effectiveness and helps save money.

Use Recycled or Budget Materials

Many users look for ways to reduce the cost of 3d printing materials. Recycled filaments and budget options can help lower costs, but they come with trade-offs.

User reviews and lab tests show several important points:

- Recycled filament may have impurities and inconsistent diameter, which can lower print quality.

- Using recycled materials can cut costs significantly, but print quality may decrease by about 25% after secondary printing.

- Recycled PLA can work as an alternative to new PLA if manufacturers control its properties.

He or she should weigh the cost savings against the potential drop in quality. For non-critical parts or prototypes, recycled filament offers a cost-effective option. For functional or high-detail prints, new filament may provide better results.

Source Materials Smartly

Smart sourcing strategies help users manage the cost of 3d printing projects. Bulk purchasing and supplier marketplaces offer ways to lower costs and ensure a steady supply of 3d printing materials.

The following table highlights best practices for sourcing materials:

|

Best Practice |

Description |

|---|---|

|

Bulk Purchasing |

Negotiate quarterly contracts through Amazon Business for 15-25% discounts. |

|

Supplier Marketplaces |

Use platforms like Amazon for consistent quality and competitive pricing. |

|

Dual-Supplier Redundancy |

Establish redundancy for critical materials to ensure supply continuity. |

Bulk buying often leads to lower prices per kilogram, especially for frequently used filaments. He or she should compare suppliers and look for deals on trusted platforms. Establishing relationships with multiple suppliers helps avoid shortages and keeps costs predictable.

Tip: Always check the printer bed for flatness and use high-quality, dry filament. These steps prevent failed prints and wasted materials, which can increase costs.

Choosing cost-effective filaments, using recycled or budget materials, and sourcing supplies smartly all help lower the cost of 3d printing. These strategies allow users to maximize value and reduce unnecessary expenses.

Optimize 3D Printing Settings to Save Money

Fine-tuning 3d printing settings can make a big difference in the cost of 3d printing projects. By adjusting printer parameters, users can reduce material waste, lower energy use, and improve the overall value of their prints. These strategies help both hobbyists and professionals save money while maintaining quality.

Adjust Layer Height and Speed

Layer height and print speed play a major role in the efficiency of 3d printing processes. Lowering the layer height increases print accuracy, but it also extends print time and may use more electricity. On the other hand, increasing print speed can finish jobs faster, though it might reduce surface quality.

- Lower layer heights enhance detail but lead to longer print times.

- Reducing infill density speeds up printing but can affect the strength of the object.

- Balancing these settings is crucial for cost-effective and efficient 3d printing.

Selecting the right combination of layer height and speed allows users to optimize the cost of 3d printing without sacrificing quality. Many 3d printers offer preset profiles that help users find this balance quickly.

Tip: Test different settings on small models before starting large projects. This approach helps identify the best balance between print quality and cost.

Minimize Infill and Wall Thickness

Infill and wall thickness settings have a direct impact on material usage and print strength. Fine-tuning these parameters can help users save on costs while still producing durable parts.

- Adjusting infill density optimizes the strength and weight of a print.

- Choosing the right wall thickness ensures strength and durability.

Design Strategies to Cut 3D Printing Cost

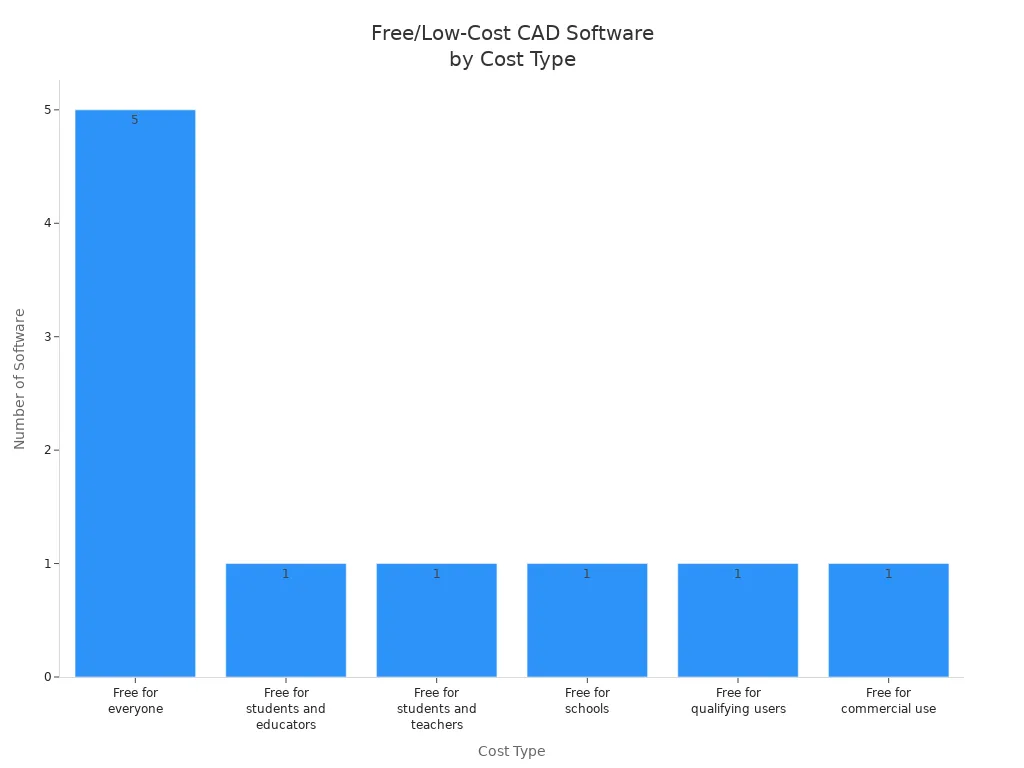

Use Free or Low-Cost CAD Software

Choosing the right software is a key step in reducing the cost of 3d printing. Many free or low-cost CAD tools offer strong features for 3d design. These programs help users avoid high upfront costs and still create quality models. The table below compares popular options:

|

Software |

Key Features |

Best For |

Cost Type |

|---|---|---|---|

|

Craftcloud |

CAM, collaboration, cloud features |

Noncommercial projects |

Free for students/educators |

|

SketchUp Free |

Web-based, 10 GB storage, 3D Warehouse |

Architecture, landscaping |

Free for schools |

|

Onshape |

Live collaboration, robust engineering tools |

Mechanical parts, complex objects |

Free for qualifying users |

|

Vectary |

Real-time rendering, 3D assets |

Artists, 2D design experience |

Free for commercial use |

|

FreeCAD |

Open-source, parametric modeling |

General CAD tasks |

Free for everyone |

|

Solid Edge |

Simulation, 3D printing features |

Mechanical/electrical design |

Free for students/teachers |

|

Blender |

Modeling, sculpting, rendering |

Professional 3D modelers, game devs |

Free for everyone |

|

OpenSCAD |

Parametric, code-based UI |

Coders |

Free for everyone |

|

NanoCAD |

Drafting/designing tools |

Advanced users |

Free for everyone |

|

LibreCAD |

Lightweight 2D CAD, cross-platform |

Basic 2D modeling |

Free for everyone |

Open-source software gives small businesses and students a way to save money and add value to their 3d printing processes. Proprietary tools may offer more support but often increase costs.

Hollow Models to Save Filament

Hollowing out 3d models is a proven way to lower the cost of 3d printing. This design technique reduces filament use and keeps the part strong. Many users report that hollow models use less material and cut costs without hurting quality. Lattice patterns inside the model can also help. These design considerations make a big impact on the total costs of a project.Tip: Hollow models work best for non-structural parts or display items.

De

sign for Fewer Supports

Good design can reduce the need for supports, which lowers costs and saves time. Designers should align critical features with the print bed and maximize bed contact. Angled overhangs and gradual transitions help avoid extra supports. Less support means less material, fewer post-processing steps, and lower costs.

- Complex 3d models often need more supports, which increases the cost of 3d printing.

- Simple shapes and smart orientation help save money and improve efficiency.

Careful design choices lead to better results and more value from every 3d print.

Workflow and Maintenance to Reduce Cost

Fix Failed Prints Efficiently

Failed prints can increase costs quickly. He or she can address these issues by identifying the most common causes, such as poor model preparation, incorrect machine settings, or unstable build plates. Quick action helps reduce waste and save money. Some effective methods include:

- Isolating problem areas, like deep cavities or steep overhangs, to reduce support needs.

- Adding alignment features, such as snap-fits or tabs, to improve structural strength.

- Increasing bed contact with larger bases to prevent warping.

- Avoiding tall, slender features by using wider bases for stability.

- Optimizing wall thickness to reinforce weak spots.

He or she can also repurpose failed prints. For example, turning waste into recycled filament, creating art, or using scraps as tools adds value and reduces costs.

Maximize Filament Usage

Maximizing filament usage helps lower costs in 3d printing processes. He or she can use leftover filament for creative projects, such as keychains or small toys. Planning print jobs by arranging multiple parts together minimizes idle time and reduces waste. These strategies help users get the most value from every spool.

Tip: Organize filament spools by color and type to track usage and avoid unnecessary purchases.

Maintain Your 3D Printer

Regular maintenance prevents breakdowns and extends the lifespan of 3d printers. Simple daily and weekly tasks can save money and reduce long-term costs. The table below shows common maintenance tasks and their benefits:

|

Maintenance Task |

Frequency |

Estimated Cost Savings |

|---|---|---|

|

Daily nozzle cleaning |

Daily |

Prevents costly repairs |

|

Lubricating moving parts |

Weekly |

Extends lifespan, reduces downtime |

|

Belt tensioning |

Monthly |

Avoids expensive replacements |

|

Cleaning the build plate |

Weekly |

Ensures high-quality prints |

A study shows that proper maintenance can extend printer life by up to 30%. These habits help users avoid expensive repairs and keep 3d printing projects running smoothly.

Extra Tips to Save Money on 3D Printing

Reuse and Repurpose Prints

Many users find that reusing and repurposing failed or obsolete 3d prints leads to significant cost savings. They can use a filament recycling system to turn old prints into new filament, which reduces material expenses. Some people combine failed ABS prints with acetone to make useful slurries or glues. Others melt scraps to create new items, such as coasters or keychains. Educators often use failed prints as teaching tools for beginners. If repurposing is not possible, recycling services can help divert waste from landfills. These practices not only lower costs but also support a circular economy. As of 2019, only 9% of plastic waste was recycled, so every effort to reuse 3d materials adds value and reduces environmental impact.

Consider Digital Inventory

A digital inventory of 3d models helps users avoid unnecessary physical storage and cuts costs. By producing parts only when needed, companies reduce material waste and storage energy. This just-in-time approach prevents overproduction and lowers the risk of unused parts piling up. Industries such as aerospace, healthcare, and defense use digital inventories to improve efficiency and sustainability. Decentralized production also reduces transportation emissions and packaging waste, which further increases money savings.

Factor in Labor and Time

Factoring in labor and time can greatly affect the total cost of 3d printing projects. Automation and robotics integration in 3d processes can reduce project timelines by up to 60% and labor costs by as much as 80%. Proper calibration and matching slicing profiles to materials help minimize waste. Monitoring the early stages of printing allows users to catch problems quickly, protecting both budget and resources. Automating post-processing steps and designing parts for easy cleaning also lead to additional savings. These strategies maximize value and make 3d printing more cost-effective.

Industry experts highlight three top ways to save money:

- Decentralizing supply chains

- Rapid in-house prototyping

- Reducing inventory and waste

Many companies report major savings. For example, Volkswagen Autoeuropa cut costs by €475,000 in two years. Small changes in materials, settings, and workflow can lower 3d printing cost.

Share your own strategies and help others save!

FAQ

What is the cheapest filament for 3D printing?

PLA usually costs the least. It works well for most projects. Many users choose PLA for its low price and easy printing.

How can someone avoid wasting filament?

He or she should check printer settings before each job. Testing with small models helps catch errors early. Careful planning reduces waste.

Does regular maintenance really save money?

Yes. Regular maintenance prevents breakdowns. It keeps the printer running smoothly. This habit lowers repair costs and extends printer life.