You want your Sovol 3d printer to make smoother prints. Start with upgrades that show clear changes. Linear rails help stop shaking and make prints look better. Dual Z motors help level the bed, so you get fewer mistakes. An all-metal hotend lets you use hotter settings and more materials. Printing speed is important, but these upgrades help you go faster and keep good quality.

|

Upgrade |

Benefit |

|---|---|

|

Linear Rails |

Better detail, less shaking |

|

Dual Z Motors |

Easier bed leveling |

|

All-Metal Hotend |

Hotter temps, more material choices |

You will see easy steps for each upgrade. Get ready to make your 3d prints faster and better.

Key Takeaways

- Upgrade to linear rails for smoother movement and better print detail. This helps stop shaking and makes prints look nicer.

- Install a dual Z motor system to make bed leveling easier. This helps you get a more even first layer and fewer mistakes.

- Switch to an all-metal hotend to print with more types of materials at higher temperatures. This lets you print faster and helps stop clogs.

- Think about a direct drive conversion for better filament control. This upgrade helps with retraction and makes prints better, especially with flexible filaments.

- Regular maintenance and calibration are important to keep your Sovol printer working well. Clean the parts, check the wires, and change settings often for the best results.

Sovol 3D Printer Hardware Upgrades

Extruder Upgrades

You can make your Sovol 3d printer work better by changing the extruder. A new extruder helps prints look smoother. It also stops blobs and gaps from happening. The StealthBurner extruder is strong and works with many filament types. It can use flexible and composite filaments. This upgrade makes extrusion more even and lowers clog risks.

|

Stiffer frame |

Less vibration |

|

New stepper motors |

Smoother movement |

|

Better motor drivers |

Fewer artifacts |

|

Firmware update |

Improved compensation |

After you put in a new extruder, check the tension. Make sure the filament path is straight. Update your firmware to get the best results from upgrades.

Hotend Upgrade

A hotend upgrade lets you use more filament types. You can also print at higher temperatures. The MicroSwiss FlowTech hotend is a top pick for Sovol users. It works well with high heat and does not clog easily. This means you can print faster and get better prints.

Do these steps after you install a new hotend:

- Use

M303 E0 S200 C8for PID tuning. - Preheat the bed and level it with paper.

- Set the Z-offset so the nozzle is at the right height.

- Calibrate E-steps to feed the right filament amount.

- Check wall thickness to fine-tune flow rate.

Part Cooling Fan

A strong part cooling fan cools prints evenly. This stops warping and helps layers stick together. For Sovol printers, use the Hotend Cooling Fan Combo for Sovol Zero/SV08 MAX. It has a 2515 Axial fan and a 5020 Blower. The 4020 Axial Cooling Fan is good for mainboard cooling.

- Hotend Cooling Fan Combo for Sovol Zero/SV08 MAX

- 4020 Axial Cooling Fan for Sovol Zero

The Sovol SV08 Max cooling system cools filament evenly. This stops warping and makes layers bond tightly. For PLA, use high fan speeds for more detail. For PETG and ABS, use lower fan speeds to keep prints strong and stop warping.

Bed Leveling

Bed leveling is important for smooth prints. You can pick from different ways to level the bed. Automatic bed leveling, like Eddy Current or BLTouch, saves time. It gives better results than manual leveling.

|

Contactless |

Speed |

Precision |

Durability |

Ideal For |

|

|---|---|---|---|---|---|

|

Eddy Current |

Yes |

Fast |

High |

Very High |

Large-format/industrial |

|

BLTouch |

No |

Medium |

Good |

Moderate |

Desktop printers |

|

Capacitive |

Yes |

Medium |

Moderate |

Sensitive |

Smooth non-metal beds |

|

Manual |

No |

Slow |

Variable |

N/A |

Entry-level users |

|

Automatic Leveling |

Manual Leveling |

|

|---|---|---|

|

Ease of Use |

Makes leveling easy for everyone |

Needs skill and takes time |

|

Print Consistency |

Keeps bed level and reduces mistakes |

Uneven prints if not done right |

|

Setup Time |

Saves time |

Takes longer with manual adjustments |

|

Adjustment Precision |

Fixes bed problems automatically |

Lets you adjust by hand |

Eddy Current leveling is fast and very precise. It is best for big printing jobs. BLTouch works well for desktop Sovol printers. After you add a new leveling system, check the first layer. Make sure it sticks to the bed.

Direct Drive Conversion

Changing to a direct drive system is a great upgrade for Sovol printers. Direct drive makes retraction easier. It stops oozing and improves print quality. It also helps with flexible filaments and keeps extrusion smooth.

|

Benefit |

Description |

|---|---|

|

Easy Retraction |

Direct drive makes retraction better and stops oozing. |

|

Easy Extrusion |

It gives smoother extrusion for high-quality prints. |

|

Filament Versatility |

Direct drive works with many filament types and keeps prints good. |

|

Lower Power Consumption |

It uses less power because the extruder is close to the nozzle. |

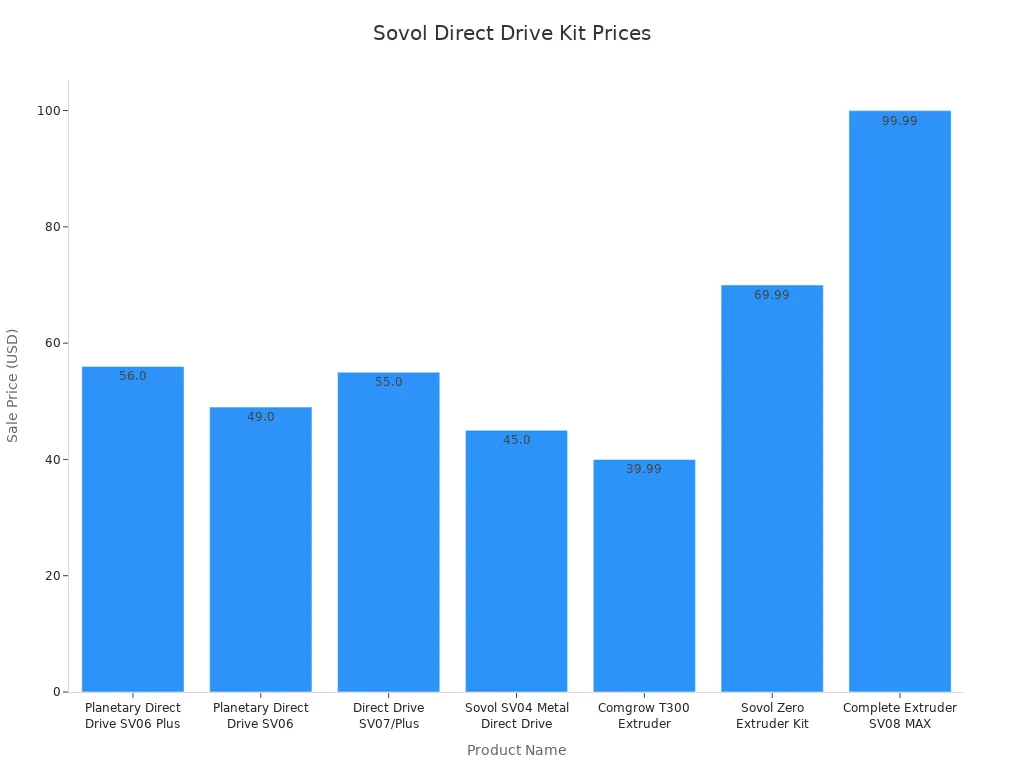

You can pick from many direct drive kits for Sovol printers:

|

Sale Price (USD) |

||

|---|---|---|

|

Planetary Direct Drive Extruder for SV06 Plus |

$56.00 |

|

|

Planetary Direct Drive Extruder for SV06 |

$49.00 |

|

|

Direct Drive Extruder for SV07/Plus |

$55.00 |

|

|

Sovol SV04 Metal Direct Drive Extruder |

$45.00 |

|

|

Comgrow T300 Extruder |

$39.99 |

|

|

Sovol Zero Extruder Kit |

$69.99 |

|

|

Complete Extruder Assembly Kit for Sovol SV08 MAX |

$99.99 |

Other Key Hardware Upgrades

You can make your Sovol printer safer and more reliable with a power supply upgrade. The Mean Well PSU gives steady power. It runs quietly and keeps the printer cool during long prints.

- The Mean Well PSU has a smart fan to lower noise.

- It cools the printer only when needed for safety.

Moving the filament runout sensor helps too. Change the wiring and keep the filament path straight. This stops false runout triggers and makes printing more reliable. Use M5x16mm hex bolts and M4 captive nuts to hold the sensor arm. Print the arm at a 45-degree angle for best results.

Note: These upgrades help you print faster, safer, and with better quality. Always test your Sovol printer after each upgrade to make sure it works right.

Speed and Quality Optimization

Print Speed Mods

You can boost the speed of your Sovol 3D printer without losing quality. Start by adjusting layer height and nozzle size. A taller layer height increases 3d print speed, but you may see less detail. A smaller layer height gives high detail, but slows down the print. You need to find the right balance for your project.

- Change print speed settings in your slicer. Start with medium speed and increase it slowly.

- Use acceleration and jerk settings to improve performance. Lower values help with surface quality.

- Select filament types that match your speed and quality needs.

Try this simple test to find the best trade-off between speed and quality:

- Print a vertical, curved wall tower at different speeds.

- Begin with slow speed at the base and increase speed as you go up.

- Check each layer for detail and surface finish.

- Look for stringing or under-extrusion.

- Measure the dimensions for accuracy.

- Choose the speed that gives you the best quality and performance.

Tip: Faster 3d print speed may need extra cooling. Adjust fan settings to keep prints accurate.

Nozzle Size

Nozzle size affects both speed and detail. A 0.4 mm nozzle balances speed and high detail for most functional parts. If you want more detail, use a 0.2 mm nozzle. This gives high detail but slows down 3d print speed. For quick prints, try a 0.6 mm or 0.8 mm nozzle. These sizes increase speed, but you lose some detail.

- Larger nozzles extrude more material, so you finish prints faster.

- Smaller nozzles give high detail, but you must lower speed.

- Pick the nozzle size based on your need for speed or detail.

Slicer Settings

Proper slicer settings make a big difference in print speed and quality. Layer height is very important. A smaller layer height, like 0.1 mm, gives high detail and smooth surfaces. A larger height, such as 0.2 mm, increases speed but lowers detail.

- Set infill patterns and density to match your model’s needs. Higher infill gives more strength, but slows down speed.

- Adjust temperature settings for each filament. PLA works best at 190-210°C. PETG needs 230-250°C. ABS needs a heated bed at 90-110°C.

- Use adaptive layer heights for models with both high detail and bulk areas. Set minimum layer height to 0.1 mm for detail and maximum to 0.3 mm for speed.

|

Slicer Setting |

Recommended Value |

Effect on Speed and Quality |

|---|---|---|

|

Layer Height |

0.1-0.3 mm |

Lower height = high detail, slower |

|

Nozzle Size |

0.2-0.8 mm |

Larger = faster, less detail |

|

Print Speed |

60-80 mm/s |

Higher = faster, may lower quality |

|

Infill Density |

15-30% |

Higher = stronger, slower |

|

Temperature |

190-250°C (by filament) |

Correct temp = better quality |

OrcaSlicer Customization

OrcaSlicer gives you advanced settings to improve performance and quality. You can use adaptive layer heights to balance speed and detail. Set a minimum layer height of 0.1 mm for high detail and a maximum of 0.3 mm for faster speed.

|

Setting Type |

Description |

Benefits |

|---|---|---|

|

Adaptive Layer Heights |

Vary layer height for detail and speed |

Sharp features, smooth transitions |

|

Z-hop |

Reduces nozzle contact with print surface |

Fewer heat defects, better quality |

|

Retraction Settings |

Adjust distance (2-4 mm) and speed (20-45 mm/s) |

Less stringing, improved performance |

|

Filament Profiles |

Set temperature and cooling for each filament |

Efficient, high-quality prints |

|

Advanced Infill |

Stronger prints, saves material |

-

For PLA, set extruder temperature to 190-210°C and fan speed to 100%.

-

For PETG, use 230-250°C and lower cooling speeds (30-50%).

-

For ABS, set heated bed to 90-110°C for better adhesion.

Experiment with advanced infill patterns, such as Adaptive Cubic, to increase strength and save material. Test retraction settings with different filaments to find the best performance.

Maintenance and Materials

Filament Quality

Picking good filament helps your 3d prints look better. High-quality filament makes prints strong and accurate. Bad filament can clog your printer and waste time. Check if the filament is even and the right size. Pure filament gives you stronger prints. Good packaging keeps filament dry and safe. Moisture can ruin your prints.

Here are some top filament brands and what they are good for your Sovol 3d printer:

|

Filament Maker |

Best For |

Features |

Skill Level |

|---|---|---|---|

|

Filament Maker TWO |

Beginners, Educators |

Easy to use, flexible design |

Great for consistent results |

|

Xplore Micro 3D |

Advanced Users |

High-quality parts, advanced features |

Needs technical skills |

|

ProtoCycler |

Beginners |

Built-in shredder, easy controls |

Simple but less customizable |

|

Felfil Evo |

Hobbyists |

Modular design, basic thermoplastics |

Limited for advanced materials |

Most people use PLA or PETG because they are easy and work well. Advanced users pick ABS for strength or Nylon for flexibility. PEEK is for high performance, but needs a special printer.

Regular Maintenance

Doing regular maintenance helps your Sovol 3d printer work well. Clean the print bed and nozzle to stop clogs. Lubricate moving parts to lower friction. Change nozzles and plates when they wear out. Tighten belts and screws to keep things working. Update firmware for best results.

- Clean rails and screws before you add lubricant.

- Check for dust, clogs, and loose parts every week.

- Watch your printer while it works to catch problems early.

Calibration

Calibration helps your 3d printer make good prints. Calibrate often to stop clogs and other problems. Change temperature settings for each filament type. Follow these steps for best results:

- Extruder Calibration: Make sure the printer pushes out the right amount of filament.

- PID Tuning: Keep the hotend temperature steady for strong layers.

- Z-Offset Adjustment: Set the nozzle at the right height for good first layers.

Calibrating often gives you smooth and reliable prints. You will get better speed and quality every time you print.

Step-by-Step Upgrade Checklist

Preparation

You need to prepare your Sovol 3d printer before you start any upgrade. Begin with regular maintenance. Clean the printer and remove dust from all surfaces. Lubricate moving parts and linear rails to keep everything running smoothly. Check the tension of the belts. Adjust them if you see any slack. Inspect all electric connections. Make sure wires are secure and not damaged. Update your firmware to get the latest features and better speed. These steps help you avoid problems and keep print quality high.

Preparation Steps:

- Clean the Sovol 3d printer and remove debris.

- Lubricate rails and moving parts.

- Check belt tension for consistent speed and quality.

- Inspect wiring and connections.

- Update firmware for better 3d printing performance.

Installation

Start the installation by reading the instructions for each upgrade. Use the right tools for your Sovol 3d printer. Remove old parts carefully. Install new hardware like extruders, hotends, or direct drive kits. Secure each part tightly. Double-check all screws and bolts. Make sure the new parts fit well. Connect wires and test each connection. Take your time to avoid mistakes.

|

Installation Step |

Why It Matters |

|---|---|

|

Remove old parts |

Prevents damage |

|

Install new hardware |

Improves speed and quality |

|

Secure connections |

Keeps 3d printing reliable |

|

Tighten screws |

Stops vibration |

Testing

After installation, you need to test your Sovol 3d printer. Run a series of test prints to check speed and print quality. Start with a simple cube. Watch for smooth layers and sharp edges. Try different filaments to see how the upgrade affects 3d printing. Adjust slicer settings for best results. Print a tower to test speed changes. Use calibration prints to check extrusion and bed leveling. Record your results for each test.

- Print a calibration cube to check quality.

- Use a speed tower to test print speed.

- Try five different test prints for accuracy.

- Test with PLA, PETG, and ABS.

- Adjust settings after each test.

Troubleshooting

If you see problems after an upgrade, you need to troubleshoot. Look for common issues like poor print quality or slow speed. Check for loose wires or screws. Run another test print to spot errors. If you see stringing or blobs, adjust retraction settings. If prints do not stick, level the bed again. Use a checklist to solve each problem step by step.

Troubleshooting Table

|

Problem |

Solution |

|---|---|

|

Poor print quality |

Recalibrate and run test prints |

|

Slow speed |

Check belt tension and firmware |

|

Bad adhesion |

Level bed and clean surface |

|

Stringing |

Adjust retraction and test |

|

No extrusion |

Inspect extruder and run test |

You can make your Sovol 3d printer work better. Upgrades help it print faster and look nicer. Add linear rails to stop shaking and get smoother prints. All-metal hotends let you use higher heat and print quicker. Dual-drive extruders hold filament tight and keep prints good. Klipper firmware gives you more control and cool features. Follow the checklist to get ready, put in upgrades, and test them. Change slicer settings to find the best speed and quality for your prints.

|

Upgrade Type |

Benefits |

|---|---|

|

Linear Rails |

Make movement smooth and steady, so prints are more exact. |

|

All-metal Hotends |

Work with high heat, stop clogs, and help you print faster. |

|

Dual-drive Extruders |

Hold filament better, feed it well, and let you print fast without slips. |

Troubleshooting helps you fix printing problems.

- Level the bed and check tramming for a good first layer.

- Look online for help with Sovol printer issues.

- Change slicer settings to make prints faster and better.

You can get smoother prints and faster printing. Keep trying new upgrades and settings. Your Sovol 3d printer will always give you great speed and quality.

FAQ

How do upgrades affect 3d printing speed?

Upgrades help you increase speed during 3d printing. A better extruder and hotend let you print faster. Direct drive systems also boost speed. You get smoother prints and finish projects quickly. Always test your Sovol 3d printer after each upgrade.

What is the best way to improve 3d print quality?

You can improve 3d print quality by leveling the bed and using high-quality filament. Upgrading the cooling fan helps layers stick better. Adjust slicer settings for your Sovol 3d printer. Good calibration makes every 3d printing project look sharp.

Can I use different filaments with my Sovol 3d printer?

You can use many filaments for 3d printing. All-metal hotends let you try PLA, PETG, ABS, and Nylon. Each filament needs different speed and temperature settings. Always check the filament type before starting a new 3d print.

Why does my 3d printer lose speed after upgrades?

Your Sovol 3d printer may lose speed if belts are loose or firmware is outdated. Check all connections and tighten screws. Clean moving parts to keep 3d printing smooth. Run test prints to find the best speed for your upgrades.

How often should I calibrate my Sovol 3d printer?

You should calibrate your Sovol 3d printer before every big 3d printing project. Calibration helps you keep speed and quality high. Adjust the extruder, bed, and temperature settings. Regular calibration stops problems and keeps your 3d prints looking great.