You will see big open source 3d printer changes in 2025. Decentralized manufacturing lets you get more 3d printing designs. Crowdsourced model libraries give you millions of good designs. Community-driven hardware ideas help you upgrade your 3d printer. This makes your printer work better and lets you change it. You can change hardware and software. You can use generic parts and try new materials. These new ideas help the planet and fix supply chain problems. But strong price competition and patents slow down open source 3d printing. Companies want to protect their 3d printing ideas. Even with these problems, 3d printing in 2025 will have teamwork. There will be a focus on additive manufacturing, new materials, and helping the planet.

Key 3d printing trends for 2025:

- More decentralized 3d manufacturing and supply networks.

- Bigger crowdsourced 3d printing model libraries.

- More hardware innovation, sustainability, and materials supply.

Key Takeaways

- AI and automation help 3D printing go faster and easier. They also make it more exact. They help with design, checking quality, and remote control.

- New strong materials like carbon fiber and Kevlar are now used. These let you print tough and bendy parts for many things.

- Hybrid manufacturing mixes 3D printing and cutting. This makes smoother and better parts. It also saves time.

- Open source 3D printers cost less money. You can change the hardware and software. You can also join helpful groups.

- Recycling, making things nearby, and saving energy help the planet. These make 3D printing greener and better for Earth.

3D Printing Trends for 2025

AI & Automation

AI is changing how people use 3d printing in 2025. AI design tools help you make complex shapes faster. You do not need to do as much work by hand. Generative AI lets you build virtual worlds for games and research. You can use digital twins to see products before making them. This helps keep production the same every time. AI helpers in CAD make design easier and faster. You can use AI with VR and AR for cool design teamwork.

AI helps automate design, slicing, and picking materials. It also checks quality. You can be creative while AI does boring jobs. Remote monitoring gives you live data and alerts. This helps stop mistakes and saves time. You can control many printers in different places. This makes your work flexible and easy to grow. AI tests help you avoid build problems. You can change laser power and layer thickness for better results. These new ideas help save materials and energy.

Tip: Try AI tools like ChatGPT to learn how AI helps with 3d printing. Schools like MIT and the University of Utah teach about AI in design.

Chinese companies use AI and cloud tools for 3d printing. FacFox, Unionfab, and FlashForge give good prices and new tech. You get lower costs, more materials, and better production. These companies help open source 3d printing grow around the world.

Advanced Materials

New materials are changing 3d printing in 2025. Open source printers like Printess use special inks and gels. You can print with cell-filled inks and strong elastomers. These printers are very accurate and can print complex shapes. They mix many materials and print inside objects. This is great for research and testing.

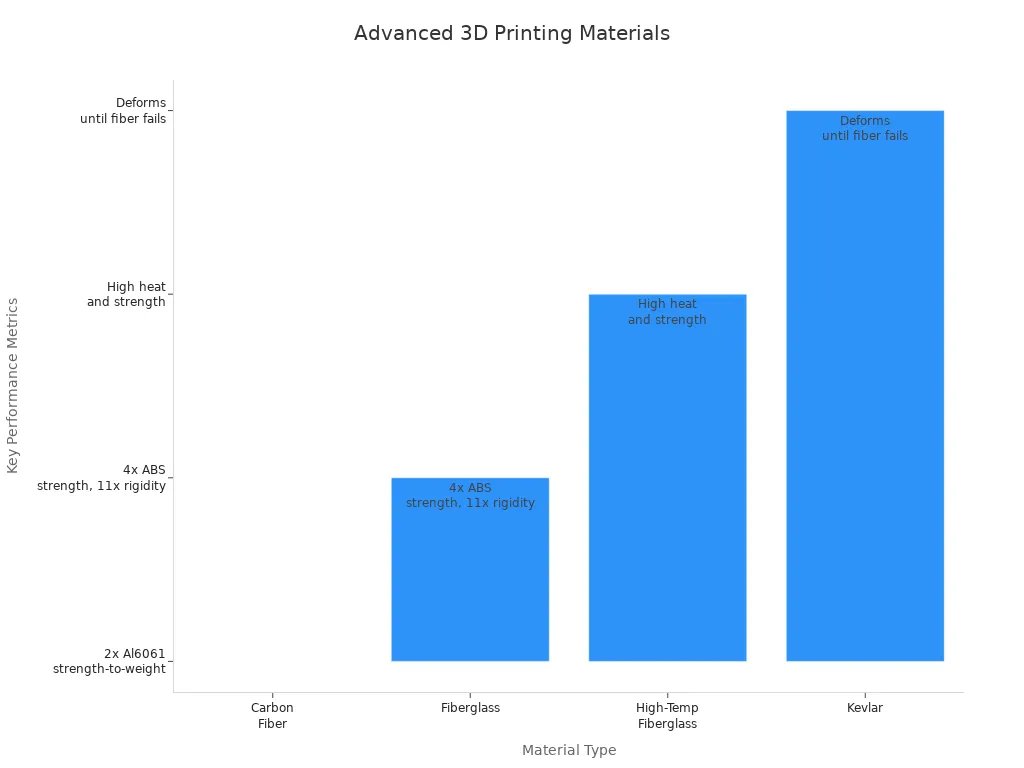

Fiber-reinforced composites are stronger than regular plastics. Carbon fiber is almost twice as strong as aluminum. Fiberglass is four times stronger and much stiffer than ABS. High-temp fiberglass can handle heat and tough jobs. Kevlar lets you print parts that bend under stress. This is good for moving parts.

|

Material Type |

Key Properties and Performance Metrics |

Applications and Notes |

|---|---|---|

|

Carbon Fiber |

Very strong and stiff; almost twice as strong as aluminum |

Used in strong plastic mixes; high strength and stiffness |

|

Fiberglass |

Four times stronger and much stiffer than ABS |

Good for tools, fixtures, and work parts; very rigid and strong |

|

High-Temperature High-Strength Fiberglass |

Handles heat and tough jobs |

Used for welding tools, molds, and forms |

|

Kevlar |

Bends until fibers break one by one; good for moving parts |

Used for parts that move and touch other things |

You can use these new materials to make things last longer and work better. Open source 3d printing lets more people try these materials and invent new things.

Hybrid Manufacturing

Hybrid manufacturing uses both adding and cutting to make parts. In 2025, you can use a 3d printer with a spindle and open source software. FreeCad and SuperSlicer help you do hybrid FFF/CNC work. You do not need to be a machining expert. This setup gives smoother parts and better quality. Layer-by-layer mixing keeps stress and heat low. This helps with cutting.

You get better parts and save time. Hybrid manufacturing lets you make hard designs and improve your work steps. Open source tools let more people use these methods.

Low prices still matter in 3d printing. Open source printers cost less than brand-name ones. You pay about $430 to make a printer. Materials can cost only $5 per project. You do not pay for licenses. You can use cheap parts and fix your printer yourself. This saves money over time. Hobbyists, small businesses, and schools like this. More people can use 3d printing. The open source community shares ideas and helps everyone learn.

In 2025, 3d printing will focus on saving time, fixing supply chains, and making more products. Chinese companies, low prices, and bigger markets push these changes. You can use these trends to work better, spend less, and keep up with new 3d printing ideas.

Open Source 3D Printer Innovations

Multi-Material Printing

Big changes are happening in multi-material printing in 2025. The BCN3D Sigma D25 uses an IDEX dual extruder system. Each extruder works by itself. You can print with different colors or materials at once. Special modes like Mirror and Duplication make printing faster and more flexible. Soluble filaments help you remove supports easily. This makes additive manufacturing smoother. The Olsson Block lets you change nozzles quickly. This fixes problems with nozzle wear and material mixing. Open source software like PrusaSlicer gives you custom supports. You can use variable layer heights. You try new settings and plugins. This helps push new ideas in 3d printing.

Bioprinting Tools

Open source extrusion bioprinters are changing things in 2025. You pay much less than for commercial bioprinters. Commercial ones cost over 10,000 €. Hobbyist printers like Prusa i3 or Ender cost under 1,800 USD/€. You use free or cheap open source software. This makes bioprinting easier for labs and hospitals. You need some skill to build and fix the printer. But you get more control and flexibility. PetriPrinter software lets you program machine movements for biology work. You can use Python or C# to set up complex motion. You can print on many culture dishes. Open source syringe pump extruders and control electronics help you print biological materials. Custom hardware parts also support new ideas in additive manufacturing.

|

Aspect |

Commercial Bioprinters |

Open-Source Extrusion Bioprinters |

|---|---|---|

|

Cost |

High, starting around 10,000 € |

Low, typically 200–1800 USD/€, based on modified hobbyist 3D printers |

|

Software |

Proprietary, user-friendly but costly |

Free or low-cost open-source, highly customizable |

|

Accessibility |

Limited by high cost and restrictions |

High, affordable and adaptable |

|

Technical Expertise |

Less skill needed |

More skill needed for assembly and operation |

|

Customization |

Limited |

High, open designs for research needs |

|

Democratization |

Restricted |

Promotes wider access and innovation |

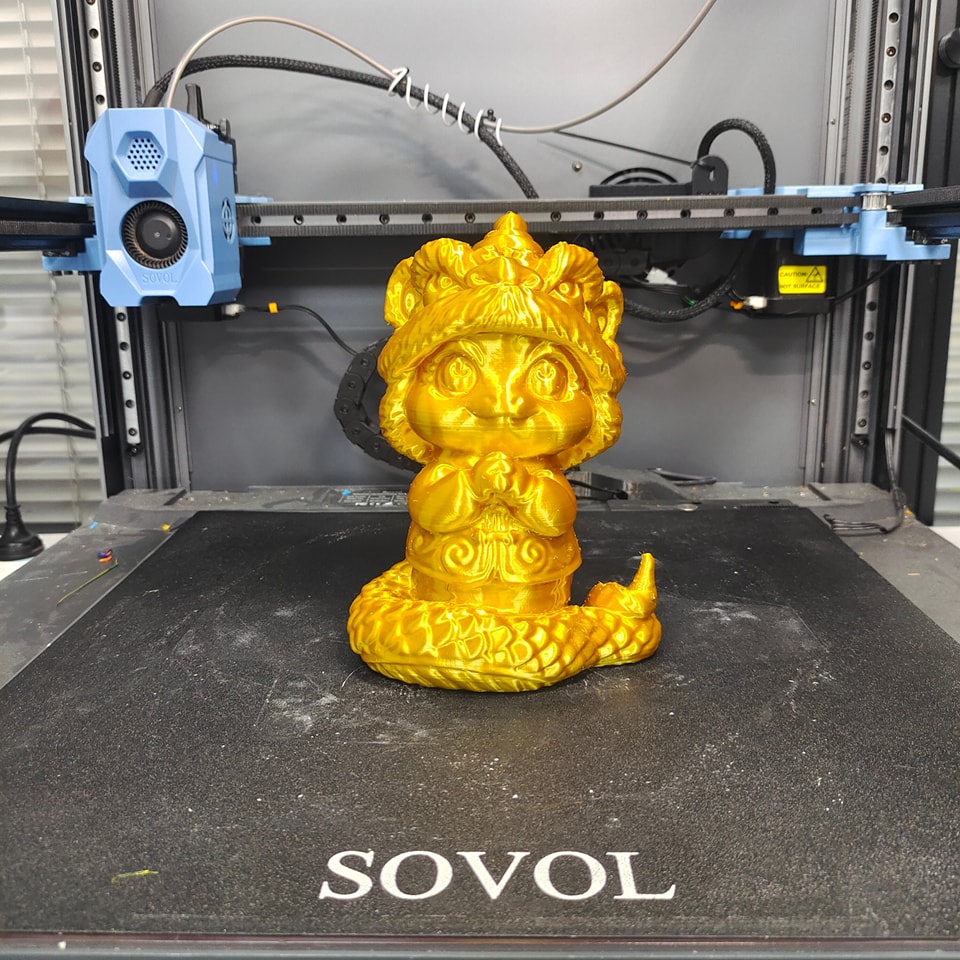

Customizability & Performance

Open source 3d printers help you customize and improve performance in 2025. You do not pay licensing fees. You use cheap parts and save money. You can upgrade hardware and software. This makes your printer more precise and useful for additive manufacturing. Open source printers use 34% more types of materials. They work up to 28% better than commercial printers. You join a community that shares designs and tips. This helps everyone keep improving. Printers like the Voron series work for special production jobs. They are often faster and print better than commercial printers. You save money and get good results. Open source 3d printers are smart for production and research.

Tip: Join open source 3d printing forums to share ideas and learn new things. You help make the future of additive manufacturing and materials better in 2025.

Software & Collaboration

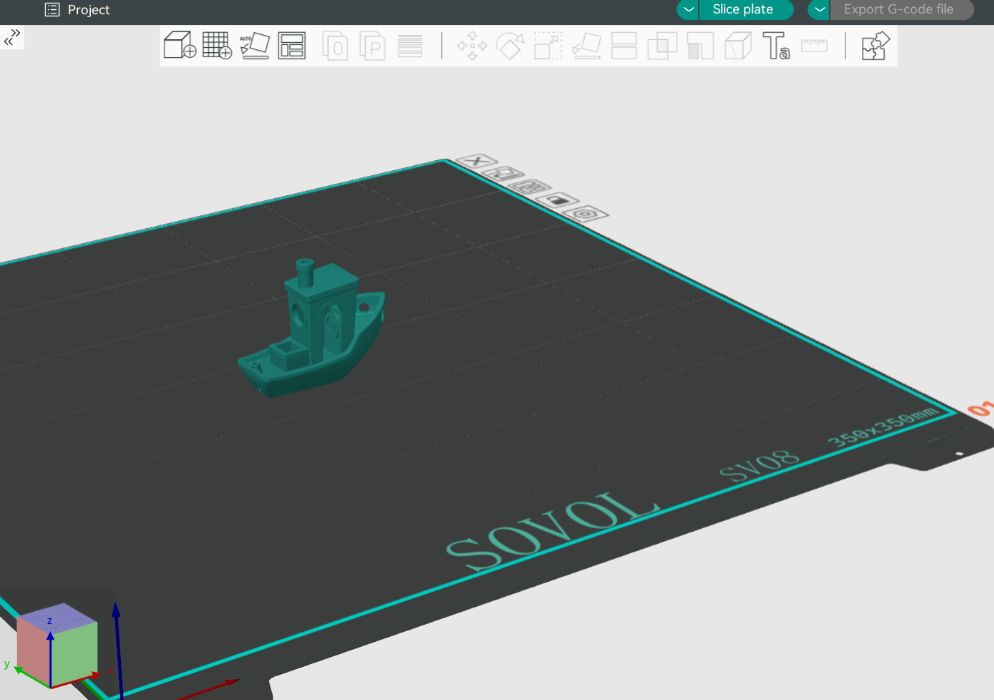

Parametric Modeling

Parametric modeling is changing a lot in 2025. FreeCAD is a top open-source 3d printing tool. You can change model settings without much trouble. You start with simple sketches and make complex shapes. FreeCAD works with many file types. This lets you move designs between different programs. You can use FreeCAD on Windows, Linux, or macOS. The FreeCAD community always works to make it better. You can give ideas and see new updates fast. This makes parametric modeling easy to use and ready for new things. In 2025, you also see more AI and workflow tools. These tools help you design faster and smarter.

Tip: Try FreeCAD if you want to learn how to do parametric modeling for 3d printing. You can join forums and ask for help.

Photorealistic Rendering

You want your 3d models to look real before you print them. In 2025, open-source 3d printing software has better photorealistic rendering tools. Blender helps you make very real-looking images. It works on many computers. You use modeling, rigging, and animation to get your 3d prints ready. You can pick real-time or offline rendering for speed or quality. New AI tools like Stable Diffusion 3D, Point-E, and DreamFusion help you make 3d models from words or pictures. These tools use neural networks to make detailed and lifelike images. You get different styles, quick results, and do not need a strong computer. You can use these tools for buildings, engineering, and making samples.

- Stable Diffusion 3D makes many views of 3d models.

- Point-E makes 3d point clouds from words in less than 30 seconds.

- DreamFusion builds 3d objects from words using AI.

User Groups & Community

You join user groups and online communities to learn and share in 2025. These groups help you fix problems and get better at using 3d printing software. You find forums, guides, and shared design files. People share upgrades, fixes, and new features. You see new ideas and changes happen fast. You do not have to wait for company updates. You can change your printer and software anytime you want. Groups like RepRap, MakerBot, and Voron show how teamwork helps open-source 3d printing. You get help if you are new or already know a lot. The community builds trust and helps shape the future of 3d printing in 2025.

|

Community Feature |

Benefit for You in 2025 |

|---|---|

|

Forums & Guides |

Fast answers and easy learning |

|

Shared Designs |

More choices for your projects |

|

Open Firmware |

Simple upgrades and fixes |

|

Educational Support |

Help for all skill levels |

Sustainability & Ecosystems

Recycling & Reuse

In 2025, recycling and reuse are very important for open source 3d printing. Many groups use a five-step plan for recycling polymers. First, you sort plastics. Next, you clean them. Then, you dry the plastics. After that, you shred them. Last, you melt and extrude them into new filament. This turns waste into useful materials for 3d printing. Projects like Precious Plastic give you open-source machines to shred and extrude plastic waste. You can build these machines with simple tools. You use them for recycling in your area. When you recycle failed prints or scraps, you make less waste and save money. Some groups recycle metal and resin too. This makes additive manufacturing better for the planet. By joining these efforts, you help the earth and support green manufacturing.

Digital Manufacturing Integration

You can make things greener in 2025 by using digital manufacturing integration. Companies like Vestas print parts close to where they are needed. This cuts down on shipping and lowers pollution. Additive manufacturing builds parts layer by layer. This means less material waste. You can use bio-based and biodegradable materials like PLA. This helps make your work better for the environment. Distributed and decentralized manufacturing lets you download files and print nearby. This supports local production and makes supply chains stronger. By choosing these ways, you help cut carbon and support a circular economy. Open source 3d printing groups use projects like Polyformer to turn plastic waste into filament. This helps local businesses and lowers the need for imports.

Energy Efficiency

Energy efficiency is important for sustainability in 2025. Additive manufacturing uses less material and energy than old methods. You print only what you need. This means less waste and lower energy use. Printing on-site makes production faster and cuts down on transport. You can pick materials that need less energy to process. Many open source projects work to make machines run better and use less energy. You help the planet by saving energy and supporting green ideas. When you use these new ways, you make manufacturing cleaner and more efficient in 2025.

Tip: Join local recycling programs and open source projects. You help build a greener 3d printing ecosystem in 2025.

Market Challenges & Opportunities

Patenting & IP

Open source 3d printing has special problems with patents and intellectual property. The law has trouble keeping up with new ways to make and share designs. It is hard to enforce patents because printers can be used for many things. Patent owners must show you knew about the patent and meant to break the rules. This is not easy to prove. A 3d model file is different from a real part, so legal claims get tricky. You also see that:

- Patents that overlap and cross-licensing slow down new hardware ideas.

- Digital files move fast, so it is hard to stop copying and changes.

- It is not easy to find out who broke the rules, even with IP addresses.

- There is no DMCA-like way to handle patents, so tools are limited.

- Suing end users costs a lot and can make people upset.

The industry is trying things like digital watermarking, DRM, and blockchain to keep designs safe. But the laws do not match the fast changes in additive manufacturing. People want better rules and more teamwork between countries in 2025.

Scalability

You need ways to grow open source 3d printing. GrabCAD Additive Manufacturing Platform helps you run many printers and manage materials. These tools let you make more things and work with Industry 4.0 systems. Standards like MQTT and OPC UA help you add new machines and software. Open-source flex printer platforms for soft robotics show you can save money and work faster. These ways to scale help you grow additive manufacturing and make supply chains stronger.

Future Outlook

In 2025, you see new chances and trends in 3d printing. Experts think additive manufacturing will let you make things when and where you need them. This means you do not need big warehouses and your supply is safer. New materials like advanced composites give you more ways to make strong parts. Big companies may get more power, and there will be more fights over IP. But automation and AI help you work faster and smarter. You see more chances to help the planet as companies care about green production and saving energy. More rules will come, especially for defense and medical uses. You will see bigger printers, better control, and new ways for small teams to make special products. In 2025, you help shape the future of additive manufacturing and supply chains.

You will notice lots of new 3d printing ideas in 2025. Open source hardware, software, and materials bring fresh trends. Cheaper printers and cool features help you make things in many fields. If you learn about green ideas and market news, you can keep up and do well. Join groups, show your designs, and try out new tools. When you use open source 3d printing, you help make new things and support teamwork and green goals.

FAQ

What is the main benefit of open source 3D printers in 2025?

You can control your printer more. You are able to change both hardware and software. You save money and try new materials. Open source printers help you learn new things and get better at printing.

Tip: Go to online forums to ask questions and share ideas with others.

Can you use advanced materials with open source 3D printers?

Yes, you can print with tough materials like carbon fiber, fiberglass, and Kevlar. You pick the best filament for your project. Open source printers make it easy to try out new materials.

|

Material |

Strength |

Use Case |

|---|---|---|

|

Carbon Fiber |

High |

Tools, fixtures |

|

Kevlar |

Medium |

Moving parts |

What software do you need for open source 3D printing?

You use free programs like FreeCAD, Blender, and PrusaSlicer. These tools help you design, slice, and make pictures of your models. You can find easy guides and videos online.

- FreeCAD: Make your model

- PrusaSlicer: Get your print ready

- Blender: Create real-looking images

How do you get support for open source 3D printers?

You join groups and talk to people online. You can ask questions in forums. You read guides and watch helpful videos. The community helps you solve problems and learn new skills.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.