Buying a 3d printer seems simple, right? Many people jump in, spot 3d printers for sale, and forget about the key points to consider. Picture this: You want to explore a new hobby, but you miss checking if the printer fits your workflow or if it’s a beginner-friendly guide for your needs. Take a look at some common things people overlook:

|

Why You Should Care |

|

|---|---|

|

Workflow compatibility |

Will your new printer work with your current setup? |

|

Learning curve and team capacity |

Is it easy for everyone to use, or just tech experts? |

|

Maintenance ecosystem |

Can you find help or parts when things go wrong? |

|

Long-term flexibility |

Will it grow with your future projects? |

|

Environmental and safety needs |

Does it meet safety standards at home or work? |

|

Total cost of use |

Are you ready for costs beyond the sticker price? |

You want the benefits of 3d printing, but you also need 3d printing tips that go beyond the basics. Remember, choosing the right printer isn’t just about specs—it’s about how it fits your life and your goals.

Key Takeaways

- Make sure the 3D printer fits your workflow. Check if it works with your setup. See if it meets your project needs.

- Think about how hard it is to learn. Pick a printer that matches your skill level. This helps you avoid getting frustrated. It also makes your experience better.

- Plan for costs that keep coming. Set money aside for maintenance. Remember you need materials and upgrades too. These costs are not just the first price.

- Learn about the types of printers. FDM, SLA, and SLS have different strengths. Choose the one that fits your goals.

- Join online groups for help. Talk with other users to share tips. Ask questions and learn from their experiences.

Buying a 3D Printer: What Most Miss

Calibration and Setup

You might think buying a 3d printer is as simple as plugging it in and pressing start. That’s a common mistake. A 3D printer is not a plug-and-play device. You need to spend time on calibration and setup before you get your first good print. This means leveling the print bed, loading the filament, and checking that all parts move smoothly. Sometimes, you have to tweak settings or run test prints to get things just right.

Tip: Don’t skip the setup steps in the manual. Even small mistakes can lead to failed prints or wasted material.

Many people believe 3d printing is hard to use because of stories from older machines. Today’s printers are much easier, but you still need patience and a little troubleshooting. If you want the benefits of 3d printing, you have to learn the basics of setup and calibration.

Maintenance Needs

Once your printer is running, you can’t just forget about it. Regular maintenance keeps your prints looking sharp and your machine running well. Here’s what most users do:

- Lubricate moving parts. About 72% of users do this, with 35% doing it monthly and 6% every week.

- Some people check their printers after every 100-200 hours of printing.

- Maintenance needs change based on your experience and the type of printer you have.

If you ignore maintenance, you might face more breakdowns or poor print quality. You don’t want to stop a project because of a clogged nozzle or a stuck motor. Keeping up with small tasks saves you time and money in the long run.

User Experience Level

Your experience with technology matters a lot when buying a 3d printer. If you’re new to 3d printing, you might find the learning curve steep at first. Take a look at how user experience affects success:

|

Impact on Expertise |

Impact on Failure Rates |

|

|---|---|---|

|

Novices |

Lower expertise |

Higher failure rates |

|

Experienced Users |

No increase in expertise |

No decrease in failure rates |

Even if you have used other gadgets, 3d printing has its own set of rules. Novices often see more failed prints and need more help. Experienced users still face challenges, but they know how to handle them faster. That’s why ease of use is so important when you pick a printer. Some models are made for beginners, while others need more skill.

Note: Don’t assume a higher price means better ease of use. Many modern printers are user-friendly and don’t cost a fortune.

If you want to enjoy 3d printing tips and get the most out of your machine, choose a printer that matches your skill level. This will help you avoid frustration and make learning fun.

Type of Printer to Buy

3D Printer Categories

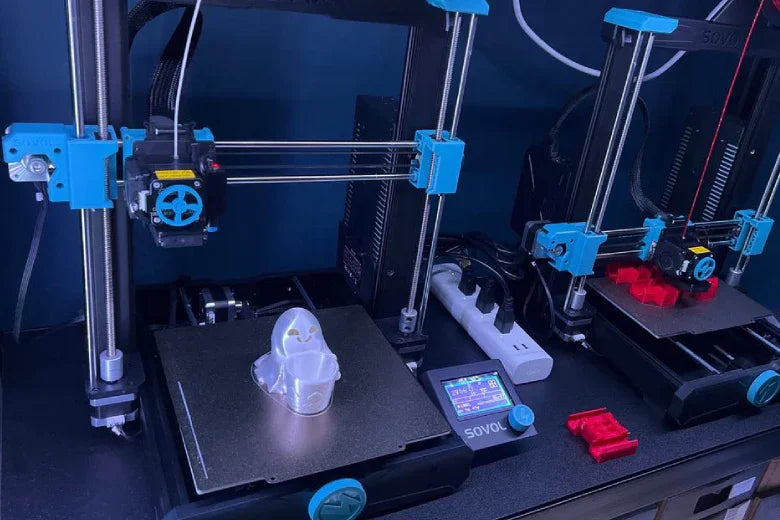

When you start looking for a good 3d printer, you will see many choices. The main 3d printer categories include FDM, SLA, and SLS. Each type of printer to buy has its own strengths. FDM printers are popular for home use and schools. SLA printers work well for people who want high quality prints with lots of detail. SLS printers are often used by companies that need strong, accurate parts. If you want to enjoy the benefits of 3d printing, you should know which category fits your needs best.

FDM vs. SLA vs. SLS

Let’s break down the differences between these three types:

|

Printer Type |

Cost |

Maintenance Requirements |

|---|---|---|

|

FDM |

Frequent nozzle cleaning |

|

|

SLA |

Higher material costs due to expensive resins |

Resin tank cleaning and light source replacement |

|

SLS |

High upfront cost but economical in the long run |

Regular laser calibration and filter replacement |

- FDM is the most budget-friendly. You can use it for simple projects and prototypes.

- SLA gives you high detail and accuracy, but the resins cost more.

- SLS costs the most at first, but you can recycle materials, which saves money over time.

If you want a good 3d printer for learning or hobbies, FDM is a smart pick. For high quality prints and accuracy, SLA stands out. SLS works best for big projects that need strong, durable parts.

Print Quality and Speed

You might wonder how these printers compare in print quality and speed. Here’s a quick guide:

- FDM printers work faster for large parts and waste less material. You can change the nozzle size to print faster, but you may lose some quality.

- SLA printers shine when you want high quality prints. They use lasers to create smooth, detailed objects, but they take longer to finish.

- SLS printers give you strong parts with good accuracy. They are great for making things that need to last.

Tip: If you want the best print quality, look at SLA printers. If you care more about speed and saving money, FDM might be your best bet.

No matter which printer you choose, always check the print quality, accuracy, and speed. These 3d printing tips will help you pick the right machine for your projects.

Material Compatibility

Supported Filaments and Resins

When you choose a 3D printer, check what 3d printing materials it uses. Not every printer works with every filament or resin. Some materials are simple to use. Others need special settings or extra care. To get the most from your printer, learn about the main options and their compatibility.

Here are the most common choices:

|

Filament/Resin Type |

Description |

Compatibility |

|---|---|---|

|

PLA |

Environmentally friendly, easy to print |

Ideal for beginners |

|

ABS |

Strong and heat resistant |

Functional parts |

|

PETG |

Combines ease of PLA and strength of ABS |

Versatile for hobbyists and professionals |

|

Standard Resins |

Good for general use |

Balanced cost and properties |

|

Tough Resins |

Mimics properties of ABS |

Durable parts |

|

Flexible Resins |

Useful for bendable parts |

Flexible applications |

Many people start with PLA because it is safe and easy. If you want stronger parts, try ABS or PETG. For resin printers, pick standard, tough, or flexible resins. Always read your printer’s manual before buying new materials.

Tip: Try different materials as you learn. You will find which ones work best for your projects and enjoy more benefits of 3d printing.

Storage and Handling

You must store your 3d printing materials the right way. If you do not, they can get wet or damaged. This can ruin your prints or even break your printer.

Here are some 3d printing tips for storing materials:

- Put filaments in bags with silica gel.

- Keep filaments away from sunlight.

- Store filaments in a dry, cool place between -20°C and +30°C.

- ABS should be kept between 15°C and 25°C.

- PVA needs a humidity-controlled place between 10°C and 30°C, with humidity below 50%.

If you follow these steps, your materials will last longer. Your prints will look better. Good storage saves money and stops waste. Remember, check compatibility and handle materials with care. This will make your 3d printing experience much easier.

Size and Build Volume

Space Requirements

Before you bring home a 3D printer, take a good look at your space. You need more than just a spot on your desk. Printers need room to breathe and work safely. If you use a desktop 3D printer, plan for at least 150 square feet per machine. This gives you enough space to move around and keeps things safe.

|

Requirement |

Details |

|---|---|

|

Ventilation |

Use a room with 5-10 fresh air changes per hour. |

|

Printer Enclosure |

Choose enclosed models for better control of fumes and dust. |

|

Space per Printer |

One printer per standard office space (about 150 square feet). |

You should also think about air quality. Good ventilation helps remove any fumes or dust from printing. If you want to run more than one printer, make sure your room has enough airflow. Enclosed printers help keep the air cleaner and safer for everyone.

Tip: Place your printer near a window or use an air purifier for extra safety.

Project Scale

The size of your printer decides what you can make. If you want to print small toys or models, a standard printer with a 200 x 200 x 200 mm build volume works well. For bigger projects like furniture or car parts, you need a large-format printer. Some industrial printers can handle huge jobs, like making molds or automotive parts.

|

Printer Type |

Build Volume (mm) |

Project Types Supported |

|---|---|---|

|

Standard Desktop |

200 x 200 x 200 |

Small objects, toys, prototypes |

|

Large Format |

500 x 500 x 500 |

Furniture, tools, architectural models |

|

Industrial Systems |

1500 x 1500 x 2000 |

Automotive, molds, large-scale projects |

Larger printers let you print big items in one piece. This saves you time and makes your projects stronger. Some large printers even let you use more than one material at a time. That means you can get creative and try new things.

When you match your printer’s size to your project goals, you unlock more benefits of 3d printing. Always check the build volume before you buy. This is one of the best 3d printing tips for getting the most out of your machine.

Budget and Ongoing Costs

Initial Price

When you look at 3d printers for sale, the first thing you notice is the price tag. Your budget will shape your choices right away. Some affordable 3d printers cost less than a new smartphone, while others can match the price of a used car. Here’s a quick look at what you might spend:

|

Category |

|

|---|---|

|

Entry-level 3D Printers |

$100 - $500 |

|

Enthusiast-level 3D Printers |

$500 - $2000 |

|

Professional 3D Printers |

$2000 - $6000 |

You want to find the best 3d printers for sale that fit your budget. Remember, a higher price does not always mean better results. Think about what you need and how much you want to spend. Balancing budget and expectations helps you avoid disappointment and enjoy the benefits of 3d printing.

Maintenance and Upgrades

Your budget does not stop at the first purchase. Every 3d printer needs care to keep running well. You will spend money on small repairs, upgrades, and regular checkups. Here’s what you might expect:

|

Maintenance Task |

|

|---|---|

|

Replacing the build plate |

$25 - $100 |

|

Changing the nozzle |

$10 - $50 |

|

Lubricating moving parts |

Negligible cost |

|

Updating software |

Usually free |

|

Calibration checks |

Can be free or fee-based |

|

Monthly Maintenance Estimate |

$20 - $200 |

You might need to upgrade parts or buy new tools as you learn more 3d printing tips. Some 3d printers for sale come with better support or longer warranties, which can save you money later. Always add maintenance to your budget plan.

Consumables

Consumables are the hidden part of your budget. You will buy filaments, resins, adhesives, and sometimes new hot ends. The cost of materials can surprise you. Many owners find that 3d printing materials cost more than they expected. Manufacturers often mark up the price of special filaments and resins. You also spend time and money on post-processing, like removing supports and cleaning parts.

Here are some common expenses:

- Filaments and resins

- Adhesives and cleaning supplies

- Replacement parts for workflow processes

- Labor for setup and post-processing

Tip: Track your spending on consumables. This helps you see the real cost-effectiveness of your 3d printer and keeps your budget on track.

When you shop for 3d printers for sale, look beyond the sticker price. Think about all the ongoing costs. This way, you get the most value and enjoy the benefits of 3d printing without surprises.

Things I Wish I Knew

Print Speed and Resolution

You might think faster is always better, but that’s not true when you print objects. If you rush, your objects can lose detail and look rough. Slower print speeds help your printer lay down each layer with care. This gives your objects sharper edges and smoother surfaces. When you want high-quality objects, you need to slow down and let the printer do its job. Quick prints save time, but you often trade away the fine details that make your objects stand out. If you want the best results, find a balance between speed and resolution. This is one of those things i wish i knew before I started.

Tip: For detailed objects, use a slower speed. You’ll see the benefits of 3d printing in every finished piece.

Post-Processing Needs

Printing your objects is only the first step. You still have work to do after the print finishes. Each type of printer needs different post-processing steps:

- FDM printers: You remove supports, fill gaps, sand, and sometimes paint your objects.

- SLA printers: You take off supports, wash away extra resin, cure under UV light, and polish your objects for a smooth finish.

- SLS printers: You brush off powder, blast the surface, and sometimes dye or treat your objects to make them stronger.

You might need to remove extra material, add coatings, or even change the color of your objects. These steps help your objects look better and last longer.

Common Red Flags

Watch out for warning signs when you use or shop for a printer. Some objects can release toxic fumes or tiny particles during printing. Fire hazards and electrical problems can also happen if you don’t follow safety rules. Sometimes, you might get hurt by moving parts or by touching hot objects or harmful materials.

- Toxic fumes and particles from certain objects

- Fire risks from faulty wiring or overheating objects

- Injuries from sharp or moving objects

If you stay alert and follow safety tips, you can enjoy the benefits of 3d printing without trouble. Always check your workspace and your printer before you start making objects.

Make the Right Choice

Setting Realistic Expectations

You want to be happy with your new printer. To do this, set goals that make sense for you. Think about what you need and what you want to make. Some people print simple models. Others want to make professional parts. You may need to fix or adjust your printer sometimes. You might have to print things more than once to get them right.

|

Description |

|

|---|---|

|

Basic Needs |

Figure out what you need and want first. This helps you pick the right machine. |

|

Technical Skills |

Be ready to fix and change your printer. Try different software settings. You may need to print parts a few times before they look good. |

|

Professional Features |

Professional printers should have a heated bed, a heated chamber, and settings for different materials. |

If you know these things, small problems will not surprise you. You will feel sure about picking a 3d printer that matches your skills and goals.

Decision Checklist

To make a good choice, use a checklist. This helps you remember what matters. Here are things to check before you buy:

|

Checklist Item |

Description |

|---|---|

|

Complete Environment |

Decide if you need only the printer or also tools for finishing prints. |

|

Print Size |

Check the build volume you need for your projects. |

|

Software Requirements |

Make sure the printer works with software you like. It is better if you pay only once for the software. |

|

After-sales Support |

Find local sellers for better help and answers. |

|

Open vs Closed Environment |

Choose if you want to use many materials or just a few. |

Use this list to help you pick a 3d printer. Think about what you want to make. Think about your space and what help you might need. If you follow this checklist, you will be ready to start 3d printing and make a smart choice.

📝 Tip: Go slow and check each step. Careful choices now mean fewer problems later.

Community and Support

Online Resources

You never have to figure out 3D printer problems alone. The internet is full of people who love to help. If you get stuck, you can ask questions or share your wins with others. Many users post tips, fixes, and even photos of their best prints.

Here are some of the most active online communities where you can find support and advice:

You can also join Facebook groups to meet other fans of 3d printing. These groups let you share photos, ask for help, or just chat about your projects.

- Maker Hacks

- 3D Printing Club

- 3D Printing for Everyone

- 3D Printing

- 3D Printer Chat

- Under Construction: Open Source 3D Printing

- 3D Printer Builders

- RepRap

- 3D Printer DIY

- 3D Printing Hobbyists

💡 Tip: If you have a question, try searching these forums first. Someone else may have solved the same problem.

Manufacturer Help

Sometimes you need help that only the maker of your printer can give. Good manufacturers offer guides, videos, and direct support. You can send them an email or fill out a form on their website. Some companies answer fast and really care about your success.

"Grateful for the exceptional team at B9Creations who went above and beyond to meet our design and printing needs. Their responsiveness and ability to move quickly saved us valuable time and helped us make critical business decisions." - Erich Dreyer | CTO at Luminelle

If you want to get the most out of your printer, check if the company has a strong support team. Look for brands with active forums or quick replies. This can make your 3d printing journey much smoother.

When you start buying a 3d printer, you want to avoid surprises. If you look at hidden factors, you make smarter choices and enjoy 3d printing more. Think about print quality, printer type, and software compatibility. Join online communities and check customer support for help.

- A checklist helps you match your needs to the right printer.

- Research printer categories and plan for costs like consumables, maintenance, and energy.

|

Mistake |

Why It Matters |

|---|---|

|

Not understanding print time |

Prints can take hours, so patience is key. |

|

Buying the wrong type |

The right printer depends on what you want to make. |

|

Choosing SLA over FDM |

FDM is easier for beginners, while SLA can be messy and complex. |

If you use a checklist of things you wish you knew, you can avoid common mistakes when buying a 3d printer.

FAQ

What is the easiest 3D printer for beginners?

You should look for FDM printers with auto-bed leveling and simple controls. Brands like Creality and Prusa make beginner-friendly models. These printers come with clear instructions and lots of online support.

How long does it take to print something?

Print time depends on the size and detail of your object. Small items can finish in an hour. Large or detailed prints may take several hours or even a whole day.

Do I need special software to use a 3D printer?

Yes, you need slicing software. This program turns your 3D model into instructions for your printer. Many printers come with free software. Cura and PrusaSlicer are popular choices.

Is 3D printing safe for kids?

3D printing can be safe if you follow rules. Always watch kids while they use the printer. Keep the printer in a well-ventilated area. Never touch hot parts or moving pieces.

Can I use any filament with my printer?

Not every printer works with all filaments. Check your printer’s manual for supported materials. PLA is the most common and easiest to use. Some printers need special settings for other types.