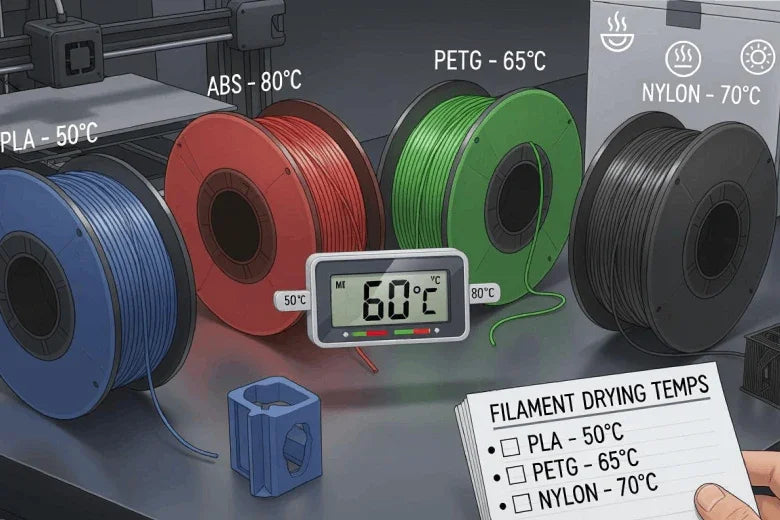

You often face issues with filament moisture that can ruin your prints. Use this quick-reference table to check the most reliable drying temperatures and times for popular materials:

|

Filament |

Temperature (°C) |

Time (Hours) |

|---|---|---|

|

PLA |

50-65 |

4-8 |

|

PETG |

55-70 |

4-8 |

|

ABS |

75-90 |

4-8 |

|

Nylon (PA) |

80-90 |

4-8 |

|

TPU |

65-75 |

4-8 |

|

PC |

85-120 |

4-8 |

|

PVB |

50-55 |

4-8 |

|

ASA |

75-85 |

4-8 |

Bookmark or print this chart for quick access. You improve print quality and avoid filament problems when you use the correct commonfilamentdryingtemperatures.

Key Takeaways

- Always dry your filament at the recommended temperature to avoid print defects. Each filament type has specific drying needs.

- Monitor the drying process closely. Overheating can warp or damage your filament, while low temperatures may leave moisture inside.

- Store dried filament in airtight containers with desiccants. This practice prevents moisture from returning and maintains print quality.

- Use a quick-reference chart for drying times and temperatures. Keep it handy to ensure you follow the best practices for each filament type.

- Look for signs of moisture in your prints, such as bubbles or stringing. If you notice these issues, dry your filament again before printing.

CommonFilamentDryingTemperatures Table

PLA

You often choose pla for its ease of use and reliability. Even though it does not absorb much water, humidity can make it brittle and cause print failures. You should dry pla at a drying temperature between 40°C and 50°C for at least 4–6 hours. If you want extra assurance, you can extend the time up to 12 hours. Periodically check the filament to prevent overheating. This practice helps you avoid stringing and weak prints.

- Drying temperature: 40°C–50°C

- Drying time: 4–6 hours (up to 12 hours for best results)

- Tip: Check the filament every few hours for signs of brittleness.

ABS

You rely on abs for strong, durable prints. Moisture can cause bubbles and poor layer adhesion. You should dry abs at around 80°C for 4 hours. Some sources suggest using the highest available temperature in your filament dryer for better results. Always monitor the filament to prevent warping.

|

Material |

Temperature (°C) |

Duration (Hours) |

|---|---|---|

|

ABS |

80 |

4 |

PETG

PETG offers flexibility and strength, but it absorbs moisture quickly. You should dry PETG at 55°C–70°C for 4–8 hours. This process reduces stringing and improves layer bonding. You will notice clearer prints and fewer bubbles when you use the correct commonfilamentdryingtemperatures for PETG.

- Drying temperature: 55°C–70°C

- Drying time: 4–8 hours

- Tip: Store PETG in a sealed container after drying.

Nylon (PA)

Nylon is highly hygroscopic and absorbs water fast. You need to dry nylon at 90°C for at least 4 hours. If the filament feels saturated, you may need to extend the drying time to 24 hours. Proper drying prevents popping sounds and weak prints.

- Drying temperature: 90°C

- Drying time: 4–24 hours (longer for saturated filament)

- Tip: Use a filament dryer for best results.

TPU

TPU is flexible and popular for wearable prints. Moisture can cause bubbles and rough surfaces. You should dry TPU at 50°C–60°C for 4–6 hours. Some sources recommend slightly lower temperatures, so you can adjust based on your equipment.

|

Source |

Recommended Temperature |

Recommended Time |

|---|---|---|

|

Geeetech |

50–60°C |

4–6 hours |

|

Wevolver |

40–45°C |

4–6 hours |

Polycarbonate (PC)

Polycarbonate needs careful handling because it absorbs moisture easily. You should use a dry box or filament dryer before printing. Dry PC at 85°C–120°C for 4–8 hours. Good adhesion and a suitable print surface are important for successful prints. You will see fewer bubbles and stronger layers when you follow the recommended drying temperatures.

- Drying temperature: 85°C–120°C

- Drying time: 4–8 hours

- Tip: Always use a dry box for PC storage.

PVB

PVB filament absorbs moisture quickly. You should dry PVB at a maximum temperature of 60°C for 4 hours before printing. This step ensures smooth prints and prevents cloudiness.

|

Material |

Max Drying Temp (°C) |

Duration (Hours) |

|---|---|---|

|

PVB |

60 |

4 |

Drying PVB helps you achieve clear, glossy prints.

ASA

ASA is similar to abs but offers better UV resistance. You should dry ASA at 80°C–90°C for about 4 hours. This process prevents layer separation and improves print strength. You will notice better results when you use the correct commonfilamentdryingtemperatures for ASA.

- Drying temperature: 80°C–90°C

- Drying time: 4 hours

- Tip: Store ASA in a dry environment after use.

You can use this section as a quick-reference guide for drying temperatures and times. When you follow these recommendations, you reduce print failures and improve the quality of your 3D prints.

Why Filament Drying Matters

Impact on Print Quality

You want your 3D prints to look sharp and perform well. Moisture in filament can ruin your results. When you skip the drying process, water inside the filament turns to steam during printing. This steam creates bubbles, weakens layers, and causes rough surfaces. You may notice stringing, faded colors, or even brittle parts.

Take a look at how moisture affects different materials:

|

Study |

Findings |

|---|---|

|

Fang et al. |

Moist polycarbonate filament reduced strength due to changes in viscosity. |

|

Hamrol et al. |

ABS with more moisture lost 25% strength and gained 10% thickness. |

|

Halidi and Abdullah |

Filament swelling from moisture caused nozzle blockages. |

|

Laumann et al. |

Moisture changed adhesion between parts and surfaces by up to 68%. |

|

Wichniarek et al. |

ABS mechanical properties dropped as moisture increased. |

You also protect your printer. Wet filament can clog the nozzle and force you to stop your project. The process of drying removes water, so you get smoother layers and better adhesion.

Risks of Incorrect Drying Temperature

You must pay attention to the drying temperature for each filament type. If you set the temperature too low, moisture stays inside. If you set it too high, you risk damaging the filament. For example, abs can warp or lose its shape if overheated.

Common print defects from wet filament include:

|

Print Defect Type |

Description |

|---|---|

|

Filament swells and blocks the nozzle. |

|

|

Visual Defects |

Stringing, faded color, and soft texture appear in your prints. |

|

Mechanical Property Changes |

Lower strength and integrity due to moisture absorption. |

|

Voids in Prints |

Steam bubbles create empty spaces, making parts brittle. |

Always follow the recommended process for drying each filament. You avoid wasted time and materials when you use the right settings.

You improve print quality and reduce frustration by controlling moisture. Proper drying keeps your projects on track and your printer running smoothly.

Filament Drying Temperature Guide

PLA Drying Temperature & Tips

You often choose pla for its reliability and ease of use. Moisture can still affect your results, so you need to follow the right process. The recommended drying temperature for pla is between 40°C and 50°C. The typical drying time is 4–6 hours, but you can extend it up to 12 hours for extra assurance.

- Store pla in airtight containers with desiccant packets to keep it dry.

- Use vacuum-sealed bags for long-term storage.

- Dry moist filament in a purpose-built dryer or a conventional oven set below 45°C.

- Crackling sounds during printing mean moisture is boiling off inside the filament.

- Increased stringing or brittleness also signal excessive moisture.

- Keep at least 200 grams of silica gel per kilogram of filament in your storage container.

- Regenerate desiccant every three months by drying it at 120°C.

ABS Drying Temperature & Tips

You rely on abs for strong and durable prints. Moisture can cause bubbles and poor layer adhesion. The recommended drying temperature for abs is 80°C for about 4 hours.

- Use a filament dryer for the most effective moisture removal.

- Place abs in an oven at 50°C–60°C for several hours if you do not have a dryer. Make sure the heating is even to avoid damage.

- For minor moisture issues, reseal the filament with desiccant packs and let it sit overnight.

Tip: Monitor the filament during drying to prevent warping. Drying abs at the right temperature ensures smooth extrusion and strong prints.

PETG Drying Temperature & Tips

PETG is popular for its flexibility and strength. It absorbs moisture quickly, which can degrade print quality. You should dry petg at 55°C–70°C for 4–8 hours.

- Use a reliable thermometer to maintain safe drying conditions.

- Avoid overdrying, as this can make the filament brittle.

- Store dried petg in airtight containers with desiccants.

- Clean and inspect your drying equipment regularly.

- Wet petg can weaken the molecular structure, leading to inferior prints.

Tip: Storing petg in a dry environment or using a filament dryer helps prevent moisture-related issues.

Nylon Drying Temperature & Tips

Nylon absorbs water faster than most other filaments. You need to dry nylon at a temperature between 70°C and 90°C. The recommended drying time is 4 to 12 hours.

- Weigh the filament before and after drying. Dry nylon should weigh about 5% less than wet filament.

- Use a filament dryer for best results.

- Store nylon in airtight containers with desiccant to keep it dry.

Tip: If you hear popping sounds or see bubbles during printing, your nylon filament still contains moisture.

TPU Drying Temperature & Tips

TPU is flexible and great for wearable prints. Moisture can ruin the filament and cause rough surfaces. You should dry TPU at 70°C for 30 minutes to 1 hour.

- Use a filament dryer or a conventional oven set to the recommended temperature.

- Check for bubbles or roughness in your prints, which indicate moisture.

- Store TPU in a dry, sealed container after drying.

PC Drying Temperature & Tips

Polycarbonate (PC) absorbs moisture easily and needs careful handling. Dry PC at 85°C–120°C for 4–8 hours.

|

Step |

Recommendation |

|---|---|

|

Drying Temperature |

85°C–120°C |

|

Drying Time |

4–8 hours |

|

Storage |

Use a dry box or airtight container |

- Always use a dry box for PC storage after drying.

- Good adhesion and a suitable print surface are important for successful prints.

- Fewer bubbles and stronger layers result from proper filament drying.

Tip: Monitor the drying temperature with an external thermometer for accuracy.

PVB Drying Temperature & Tips

PVB filament absorbs moisture quickly. You should dry PVB at a maximum temperature of 60°C for 4 hours before printing.

- Use a filament dryer or a conventional oven set to the recommended temperature.

- Store PVB in a moisture-resistant container after drying.

- Cloudiness or unclear prints signal moisture in the filament.

Tip: Drying PVB helps you achieve clear, glossy prints.

ASA Drying Temperature & Tips

ASA offers better UV resistance than abs and needs proper drying for strong prints. The recommended drying temperature is 80–90°C. Drying time is 4 to 6 hours, or up to 8 hours for heavily saturated filaments.

- Use a filament dryer or a conventional oven with careful monitoring.

- Preheat the drying device before use.

- Verify temperature accuracy with an external thermometer.

- Do not leave filament unattended during drying.

- Seal filament in a moisture-resistant container immediately after drying.

- Weigh the spool before and after drying to estimate moisture loss.

Filament Drying Tips & Troubleshooting

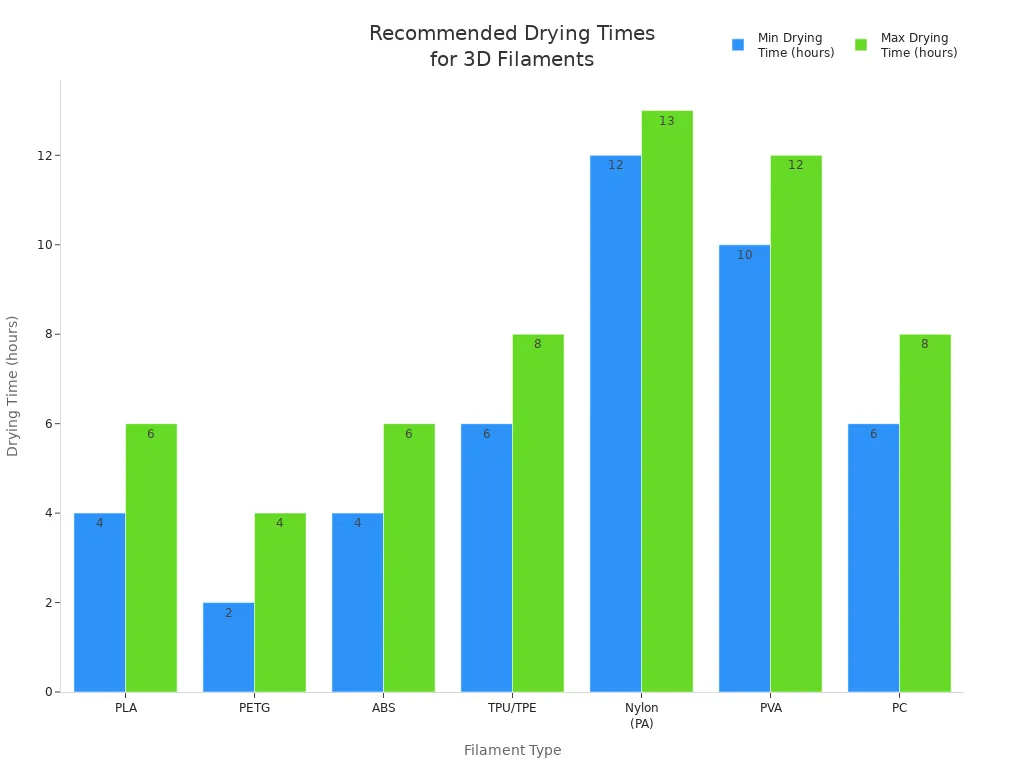

Recommended Drying Times

You need to know the right drying times for each filament type to get the best results. Manufacturers suggest specific temperatures and durations for common materials. Use the table below as a quick guide:

|

Filament Type |

Drying Temp (°C/°F) |

Recommended Time |

|---|---|---|

|

PLA |

45–50 / 113–122 |

4–6 Hours |

|

PETG |

60–65 / 140–149 |

2–4 Hours |

|

ABS |

80–85 / 176–185 |

4–6 Hours |

|

TPU/TPE |

50–55 / 122–131 |

6–8 Hours |

|

Nylon (PA) |

70–80 / 158–176 |

12+ Hours |

|

PVA |

45–50 / 113–122 |

10–12 Hours |

|

PC |

~120 / 248 |

6–8 Hours |

You should always check the recommended drying time for your filament before starting the process. Longer drying times help remove more moisture content, especially for nylon and tpu.

Key Tips for Best Results

You can follow best practices for drying to improve your print quality and avoid common problems. Here are some tips you should use:

- Maintain the recommended drying temperature for each filament type.

- Dry your filament for the suggested duration to ensure moisture is removed.

- Store filament in airtight bins with desiccants or use vacuum-sealed bags.

- Use a dry box with humidity control for long-term storage.

- Avoid overdrying by not exceeding 50°C for extended periods.

- Watch for signs of moisture damage, such as weak prints or nozzle clogs.

Signs of Moisture in Filament

You can spot moisture problems by looking for certain print defects. If you see bubbles, stringing, or faded colors, your filament may have absorbed water. You might hear popping sounds during printing, which means steam is escaping from the filament. Weak layer adhesion and rough surfaces also show that moisture content is too high.

If you notice these issues, dry your filament again before printing. You will get stronger, smoother prints when you keep your filament dry.

Remembering Drying Temperatures

Mnemonics & Memory Tricks

You can use simple tricks to remember the right drying temperatures for your filaments. Try grouping materials by their drying ranges. For example, most standard filaments like PLA, PETG, ABS, and ASA dry well between 55°C and 80°C. You might use the phrase “Fifty to Eighty Keeps Filament Ready” to recall this range. If you work with nylon or PC, remember that these need higher temperatures. You can also create a rhyme: “Nylon and PC, dry hot as can be.”

Another method is to match the first letter of the filament with its drying temperature. For instance, “P” for PLA and PETG, both around 55°C–65°C. You can write these mnemonics on sticky notes near your printer.

Tip: Use color-coded labels for each filament spool. Red for high-temperature filaments like nylon and PC, blue for mid-range like PETG and ABS, and green for low-temperature like PLA.

Printable Charts & Labels

You can make your workspace more efficient by printing drying temperature charts and labels. Place a laminated chart near your printer for quick reference. Many makers use tables like the one below to keep drying times and temperatures handy:

|

Filament |

Drying Temp (°C) |

Drying Time (h) |

|---|---|---|

|

PLA, PLA-CF |

55 |

8 - 12 |

|

PETG |

60 |

8 - 12 |

|

ABS, ASA |

65 |

8 - 12 |

|

PC |

80 - 100 |

8 |

|

TPU |

70 |

8 - 12 |

|

nylon |

80 - 90 |

8 - 12 |

You can also print small labels for each spool. Write the recommended drying temperature and time on the label. This helps you avoid mistakes during the drying process.

Rules of Thumb

You can follow some easy rules of thumb to remember drying temperatures. Most filaments dry well at 60°C for 4–8 hours. If you use specialty filaments like nylon or PC, increase the temperature to 80°C or higher. PETG usually dries at 60°C for 8–12 hours.

If you forget the exact temperature, check a chart or use the general rule: “Standard filaments at 60°C, engineering filaments at 80°C or above.”

You can keep a table like this nearby:

|

Material |

Max Drying Temp (°C) |

Duration (Hours) |

|---|---|---|

|

PLA |

65 |

4 |

|

PETG |

65 |

4 |

|

ABS |

80 |

4 |

|

nylon |

90 |

4 |

|

PC |

120 |

4 |

Safe Filament Drying Practices

Do’s and Don’ts

You need to follow safe practices when drying filament. Doing so helps you avoid damage and get better prints. Here are some important do’s and don’ts:

Do’s:

- Use a filament dryer or a convection oven with accurate temperature control.

- Check the filament’s recommended drying temperature before starting.

- Monitor the filament during drying to prevent overheating.

- Use an external thermometer for more precise readings.

- Place filament on a clean tray or rack to allow air circulation.

Don’ts:

- Do not use a microwave or toaster oven. These can melt or burn filament.

- Do not leave filament unattended while drying.

- Do not exceed the maximum recommended temperature for your filament.

- Do not dry filament in direct sunlight.

Avoiding Filament Damage

You want to keep your filament in good condition. Damage can happen if you use the wrong temperature or drying method. Follow these steps to avoid problems:

|

Risk |

How to Avoid |

|---|---|

|

Overheating |

Set the dryer to the correct temp |

|

Warping |

Use gentle heat and monitor closely |

|

Brittleness |

Avoid drying for too long |

|

Contamination |

Keep filament away from dust |

You should inspect the filament before and after drying. Look for signs of melting, discoloration, or rough texture. If you see any damage, do not use the filament for printing.

Note: Damaged filament can clog your printer and ruin your project.

Storage After Drying

You need to store filament properly after drying. Moisture can return quickly if you leave filament exposed. Use these storage tips:

- Place dried filament in airtight containers.

- Add silica gel packs to absorb moisture.

- Label each spool with the drying date and recommended temperature.

- Store containers in a cool, dry place.

- Use vacuum-sealed bags for long-term storage.

You now know the most important filament drying temperatures and how they affect your print quality. Use the quick-reference table each time you prepare your filament. Print or bookmark the chart so you always have it nearby. Proper drying helps you avoid common problems and get the best results from your 3d printing projects. Make this step a regular part of your workflow for stronger, smoother prints.

FAQ

What happens if you dry filament at the wrong temperature?

You risk damaging the filament. Overheating can cause warping or brittleness. Low temperatures may leave moisture inside. Always check the recommended temperature for your filament type.

Can you use a regular oven to dry filament?

You can use a regular oven if it has accurate temperature control. Set the oven to the recommended temperature. Monitor the filament closely to prevent overheating or melting.

How do you know if filament needs drying?

You see bubbles, stringing, or faded colors in your prints. You may hear popping sounds during printing. These signs show that the filament contains moisture.

Should you dry filament before every print?

You do not need to dry filament before every print if you store it properly. Use airtight containers with desiccant packs. Dry filament if you notice print defects or if it feels damp.