You want perfect small 3d prints, right? Sovol Zero’s special features make it the Best 3D Printer For Miniatures. The auto-leveling system helps make a great first layer. The high-temp nozzle and good control give sharp details. Users get smooth surfaces and steady results, even for hard miniature printing jobs.

Key Takeaways

- Sovol Zero's auto-leveling helps make a smooth first layer. This is important for showing tiny details in small prints.

- Set the layer height to 50µm if you want to paint. Use 20µm for display pieces to get smooth looks and clear details.

- Pick a wall thickness of at least 1.5 mm for strength. This helps your miniatures stay strong and not break when touched.

Model Preparation

Best Design for Miniatures

You want your miniature to look sharp and last a long time. Picking the best design for miniatures means thinking about how strong and detailed your model will be. Let’s check out what matters most:

|

Design Characteristic |

Importance |

|---|---|

|

Material Properties |

Your model needs impact resistance and flexibility so it doesn’t break easily. Low water absorption keeps it stable. |

|

Layer Height |

Smaller layer heights show more details and make your print look smoother. |

|

Exposure Times |

Setting the right exposure time helps you avoid rough or weak spots. |

|

Model Orientation |

Placing your model the right way keeps all the tiny details safe. |

Sovol Zero’s precision and adaptive area detection help you capture every detail. You get smoother surfaces and crisp edges, even with detailed designs.

Scaling for Miniature 3D Prints

When you shrink a design, you need to keep the details and strength. If you scale down more than 5%, rework supports and hollowing so your print doesn’t fail. For bigger models, add more supports to protect the surface details. Always test your design at different sizes to make sure it stays strong and keeps all the detailed designs.

Tip: Adjust your layer height for smaller models. This helps you keep the fine details sharp.

Wall Thickness Tips

Wall thickness matters for durability and details. For PLA, keep walls at least 1.5 mm thick. If you want extra safety, go up to 5 mm. Thin parts under 1.5 mm can break easily, so make sure your design stays solid. Sovol Zero’s precision lets you print thin walls without losing details, perfect for detailed designs.

Printer Settings

Layer Height for Miniatures

You want your miniature to show every tiny detail. Sovol Zero’s full auto-bed leveling system uses dual technology—eddy current scanning and pressure sensing. This gives you sub-micron precision when mapping the print bed. You get perfect first layers every time, which is key for capturing all the details in your model.

Picking the right layer height makes a big difference. Here’s what works best:

- If you plan to paint your miniature, set the layer height to 50µm. This gives you a smooth finish and keeps the details sharp.

- For display pieces that need the highest quality, go with 20µm or even 10µm. You’ll see every detail pop.

- Smaller layer heights, like 0.1 mm to 0.2 mm, also help you get smoother surfaces and sharper details.

- If you want to push the details even further, try a layer height of 0.05 mm. Just remember, this will take longer to print.

Tip: Sovol Zero’s accuracy and adaptive area detection help you keep all the fine details, even at tiny layer heights.

Print Speed Optimization

You want your prints to look great and finish quickly. Sovol Zero’s Pressure Advance feature helps you get high-speed printing without losing quality. It adjusts the flow of filament before the printer moves, so you get crisp details and smooth surfaces.

Here’s how you can optimize your print speed for miniatures:

- Slow down the print speed to 40 mm/s or 60 mm/s. This helps you keep sharp details and avoids problems like stringing or shifting layers.

- For parts with lots of tiny details, drop the speed to 30 mm/s. You’ll see the details stay clear and crisp.

- If you go too fast, you might lose some details and the surface could look rough.

- Find a balance between speed and quality. Sovol Zero’s Input Shaping technology lets you print faster while keeping the details sharp.

Note: Sovol Zero’s XYZ full linear rails give you smoother motion and better control, so your details stay perfect even at higher speeds.

Temperature and Cooling

Getting the temperature and cooling right is important for strong, detailed prints. Sovol Zero’s high-temp nozzle can reach up to 350°C, so you can use many different materials for your miniatures. The AC heated bed keeps the temperature steady, which helps you avoid warping and keeps the details sharp.

Check out this table for the best settings:

|

Filament Type |

Extruder Temperature (°C) |

Cooling Fan Speed (%) |

|---|---|---|

|

PLA |

190-210 |

100 |

|

PETG |

230-250 |

30-50 |

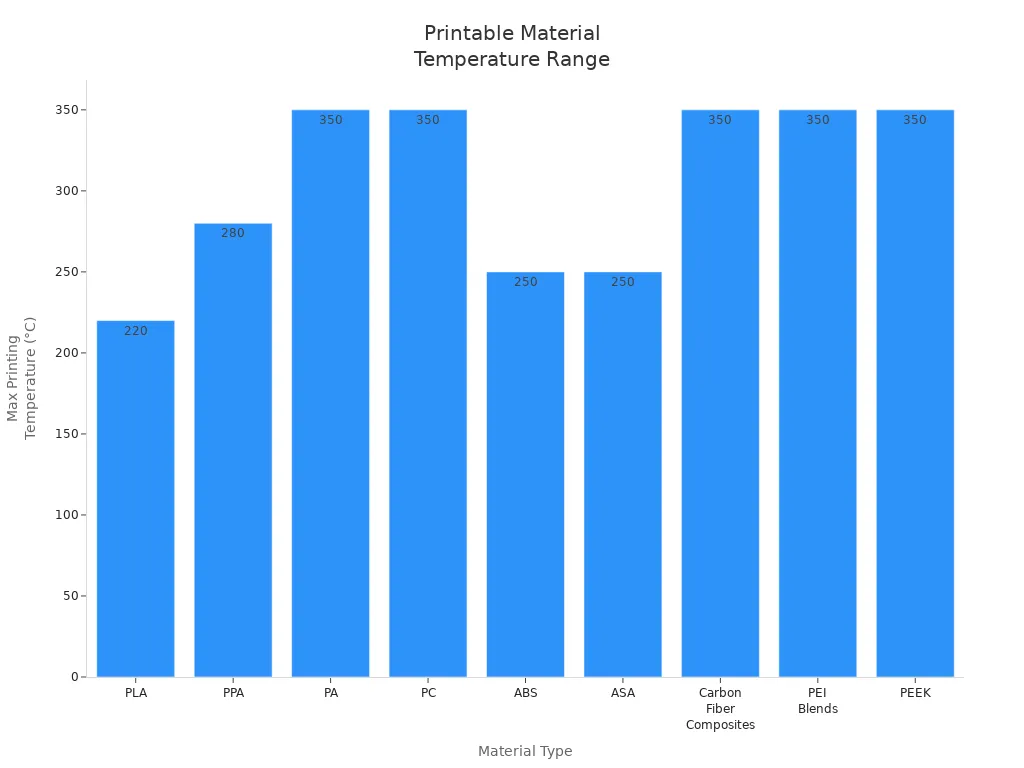

Sovol Zero’s high-temp nozzle lets you print with advanced materials. Here’s a quick look at what you can use:

|

Material Type |

Temperature Requirement |

Notes |

|---|---|---|

|

PLA |

Up to 220°C |

Common filament |

|

PPA |

260-280°C |

Advanced, tough material |

|

PA |

Up to 350°C |

Strong and durable |

|

PC |

Up to 350°C |

High impact resistance |

|

ABS |

Up to 250°C |

Good for prototypes |

|

ASA |

Up to 250°C |

UV resistant |

|

Carbon Fiber Composites |

Up to 350°C |

Enhanced strength |

|

PEI Blends |

Up to 350°C |

High-temperature applications |

|

PEEK |

Up to 350°C |

Extreme conditions |

Sovol Zero Techniques

Model Placement

Getting the right model placement on your Sovol Zero build plate can make a huge difference in your miniature prints. You want your model to stick well and show off all the details. Here are some tips to help you:

- Place your model flat on the print bed. This keeps it steady and reduces shaking during printing.

- If you have a tall miniature, tilt it a little. This helps balance the weight and stops it from tipping over.

- Use Sovol Zero’s dual auto-leveling feature. It makes sure the bed is even, so your model stays stable and sticks better.

- Try different angles in your slicer software. Sometimes, a small change in position can help you get sharper details or make the print easier to finish.

Sovol Zero’s adaptive area detection works in the background. It checks your model’s shape and adjusts the extrusion for tricky spots. This means you get better accuracy and more details, even on tiny parts.

Support Reduction

Supports help your miniature print, but too many can hide details or make cleanup harder. Sovol Zero gives you tools to use fewer supports and still get great results. Here’s how you can do it:

- Use breakaway supports. These snap off easily, so you don’t need special tools.

- Adjust the Z-gap between the support and your model. A small gap makes supports easier to remove and keeps details safe.

- Change your model’s orientation. If you tilt or rotate your miniature, you might need fewer supports. This also protects the surface details.

Support density matters, too. If you use a high density, your print gets more support, but it uses more material and can be harder to clean. A lower density saves material and makes removal easier, but it might not hold up complex parts. Try different settings to find what works best for your miniature.

Sovol Zero’s vibration damping pads help here. They absorb movement, so your supports and details stay sharp, even during fast prints.

Troubleshooting Miniature Prints

Sometimes, things don’t go as planned. Sovol Zero’s features make it easier to spot and fix problems before they ruin your miniature. Here’s a quick guide to common issues and how to solve them:

|

Impact on Quality |

|

|---|---|

|

Filament processing |

Changes how smooth your print looks and how strong it is. |

|

Materials |

Affects how tough your miniature is and how it looks. |

|

Printing parameters |

Controls the accuracy and surface quality of your print. |

You might see problems like the first layer not sticking, or the nozzle getting clogged. Here’s what you can do:

- Watch the first layer closely. If it doesn’t stick, check your bed leveling and clean the surface.

- Clean the nozzle often. A dirty nozzle can mess up the Z-offset and ruin details.

- Use Sovol Zero’s built-in camera to monitor your print. You can catch filament oozing or other issues early.

- If you see rough spots or missing details, try slowing down the print or lowering the layer height.

Sovol Zero’s full XYZ linear rails and Input Shaping technology help you get professional results. They keep the motion smooth and reduce vibrations, so your details stay crisp. The silicone damping pads make your printer quieter and your prints smoother. You can even print at high speeds, like 1200mm/s, and still get sharp details. This is great if you want to try batch-printing armies for your tabletop games.

Here’s a quick look at how Sovol Zero’s features help your miniature 3d prints:

|

Feature |

Benefit |

|---|---|

|

Full XYZ linear rails |

Smooth motion and precise layer alignment for sharp details. |

|

Sturdy frame |

Keeps your printer steady, even at high speeds. |

|

Silicone damping pads |

Absorb vibrations for smoother, quieter prints. |

|

Input shaping |

Reduces print artifacts and improves surface quality. |

|

Pressure advance |

Makes sure each layer is even and sticks well. |

|

Adaptive area detection |

Boosts accuracy and keeps details clear in tricky spots. |

|

Vibration damping pads |

Help you get smoother prints with better surface quality. |

Tip: Sovol Zero’s air filtration system keeps your workspace clean while you work on your miniature. You can focus on the details without worrying about dust or fumes.

Post-Processing

Support Removal

You want your miniature to look clean and sharp after printing. Removing supports can feel tricky, but you can do it step by step:

- Start with supports you can reach easily. Use needle-nose pliers to twist and break them off.

- Move to the supports inside your model. Try flush cutters and pliers for these tight spots.

- Take your time and be gentle. Rushing can damage your print.

- Use a craft knife for small bits or fine details.

- After you finish, sand the surface to smooth out any rough spots.

- If your print has lots of complex supports, try water-soluble supports next time.

- Adjust support settings in your slicer software for better results in future prints.

- Practice different methods. You’ll get better with each print.

Tip: Sovol Zero’s air filtration system keeps your workspace safe by removing harmful particles and fumes during post-processing.

Smoothing Surfaces

You want your miniature to have a professional finish. Here’s a quick look at ways to smooth surfaces:

|

Technique |

Description |

Advantages |

Considerations |

|---|---|---|---|

|

Bead Blasting |

Sprays tiny beads to remove layer lines |

Matte, uniform finish |

Best for FDM parts |

|

Vapor Smoothing |

Uses heated solvent vapor |

Works on many materials |

Needs special equipment |

|

Tumble Finishing |

Uses a tumbler for small parts |

Good for intricate parts |

Limited by part size |

|

Sanding & Polishing |

Removes material for smoothness |

Very smooth finish |

Takes time and effort |

You can also try priming and sanding, using solvents, or applying epoxy for a glossy look. An air eraser helps with hard-to-reach areas.

Painting Miniatures

Painting brings your miniature to life. Start by cleaning the surface and using a primer. Choose paints made for models. Use thin layers and let each coat dry. Small brushes help you reach tiny details. Take your time and enjoy the process. Good painting shows off the accuracy of your print.

Best 3D Printer for Miniatures

If you want a great 3d printer for miniatures, Sovol Zero has what you need. It has special features that make printing simple and fun. The CoreXY system keeps shaking low, so your miniatures show every tiny detail. The high-temperature nozzle lets you use many filament types. Linear rails help the printer move smoothly and with accuracy.

Here’s why Sovol Zero is the best 3d printer for miniatures:

|

Feature |

Description |

|---|---|

|

CoreXY System |

Cuts down on shaking, so your prints look neat and clear. |

|

High-Temperature Nozzle |

Heats up to 350°C, works with lots of filaments for smooth results. |

|

Linear Rails |

Gives you steady and exact movements for better prints. |

|

Dual Auto-Leveling |

Makes setup easy, so you get a perfect first layer every time. |

You don’t need to worry about hard setup steps. Sovol Zero’s touchscreen shows you what to do, and auto-leveling saves you time. Most people say it’s their favorite printer because it’s quick, dependable, and simple to use. You can print with ABS, PLA, or other special filaments easily.

People like the strong frame and built-in camera. You can watch your print and see time-lapse videos. The damping pads keep the printer steady, so your prints look great. The best 3d printer for miniatures should give you pro results with little work, and Sovol Zero does this well.

Want to try new designs or materials? Sovol Zero helps you do it fast and with less waste. You get top-quality prints every time.

Sovol Zero’s smart features help you make perfect miniatures. The CoreXY structure keeps the printer steady and smooth. Auto-leveling makes setup simple and fast. The high-temp nozzle lets you use different materials. You can try new settings and printing tricks. Make tabletop figures, gifts, or cool models to show your creativity. Sovol Zero helps you think of new ideas and bring them to life!

FAQ

How do you clean the Sovol Zero after printing a miniature?

You can wipe the bed with a soft cloth. Remove leftover filament. Use the air filtration system to keep your workspace fresh.

What filament works best for miniatures on Sovol Zero?

PLA prints easily and shows fine details. You can also try ABS or PETG for stronger models. Sovol Zero supports many filament types.

Can you watch your print in real time?

Yes! Sovol Zero has a built-in camera. You can check your print progress and even make time-lapse videos.

Tip: Always check your first layer. It helps you avoid print issues later.