When you use a 3D printer, the nozzle acts as the tiny opening where melted filament comes out to form your objects. Some printers use just one nozzle, while others use two or more for advanced projects. The size and material of the nozzle make a big difference in your results.

|

Nozzle Size |

Print Quality |

Speed |

Strength |

|---|---|---|---|

|

Great for fine details |

Slower |

Weaker |

|

|

Larger |

Less detail, more speed |

Faster |

Stronger |

You can pick a smaller nozzle for detailed work or a larger one for faster, sturdier prints. The right choice helps you get the best results for your project.

Key Takeaways

- Pick the right nozzle size for your project. Small nozzles make fine details. Big nozzles print faster and make stronger parts.

- Choose the nozzle material for your filament type. Brass works well for normal filaments. Hardened steel is best for rough materials.

- Clean and check your nozzle often to stop clogs. This helps keep your prints smooth and avoids problems.

- Think about how many nozzles your printer has. One nozzle is easier for beginners. More nozzles let you do harder projects and use more colors.

- Change your nozzle if you see it is worn out. Look for dull tips or rough print surfaces. Changing it on time gives you better prints.

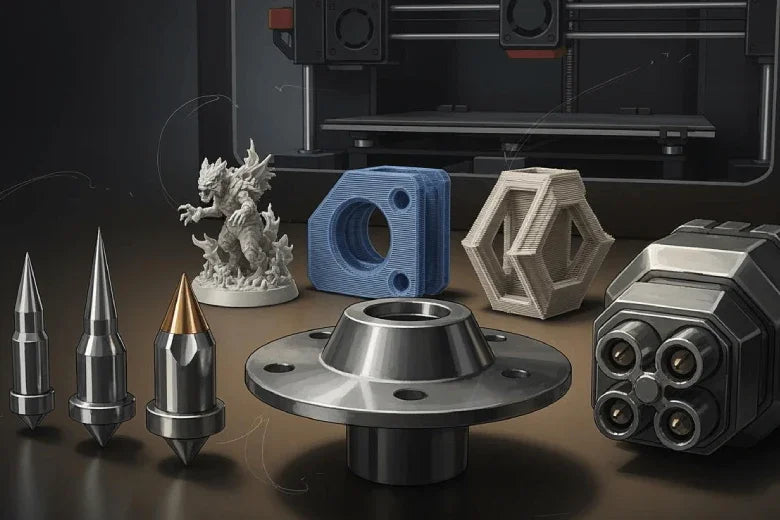

3D Printer Nozzle Basics

What Is a Nozzle?

You can think of the nozzle as the tip of your 3D printer’s hot end. This small part controls how melted plastic leaves the printer and lands on the print bed. The nozzle looks like a tiny metal cone with a hole at the end. You screw it into the hot end, and it heats up during printing. The size of the hole in the nozzle decides how thick each line of plastic will be.

Most nozzles use brass, but you can also find steel or other metals. Each material has its own strengths. Brass heats up quickly and works well with common filaments. Steel nozzles last longer if you use rough or special filaments. You can swap nozzles to match your project or filament type.

Tip: Always check your nozzle size before starting a new print. The wrong size can affect your print’s detail and strength.

Nozzle’s Role in 3D Printing

The nozzle plays a key role in every 3D printer. It melts and shapes the filament, turning it into the layers that build your object. The nozzle’s size and material affect how your prints look and how strong they are. A smaller nozzle gives you fine details, while a larger one prints faster and makes thicker walls.

Here’s what the nozzle does in a 3D printer:

- Heats up to melt the filament.

- Controls the flow of melted plastic.

- Shapes each layer of your print.

- Affects print speed and quality.

If you want smooth surfaces and sharp corners, choose a smaller nozzle. If you need a strong, quick print, pick a larger one. The right nozzle helps you get the best results from your 3D printer.

How Many Nozzles Does a 3D Printer Have?

Single Nozzle Setups

Most home 3D printers have just one nozzle. You use one filament at a time. This makes printing simple for beginners. There are fewer parts to worry about. It is easier to fix if something breaks. You can change the nozzle size for different jobs. For example, a 0.4mm nozzle works for most prints. A 0.2mm nozzle is good for tiny things like jewelry.

|

Nozzle Size |

Best For |

|---|---|

|

0.2mm |

Miniatures, Jewelry, fine detail |

|

0.4mm |

All-purpose Use |

|

0.6mm |

Stronger parts, faster prints |

|

0.8mm |

Prototypes, large and thick layers |

|

1.0mm |

Extra-large prints, high-speed builds |

|

1.2mm |

Industrial applications, rough drafts |

Single nozzle printers are great for most projects. They are easy to use and give steady results. You do not need to mess with tricky settings or extra parts.

Tip: If you want to use special filaments, like glow-in-the-dark or wood-filled, switch to a steel nozzle. This helps your printer last longer.

Dual and Multi-Nozzle Options

Some printers have two or more nozzles. You can print with more than one color or material. Dual extruder systems let you change filaments fast. You might use one nozzle for hard plastic and another for soft rubber. Multi-nozzle printers help you make objects with more features.

|

System Type |

Advantages |

Challenges |

Use Case |

|---|---|---|---|

|

Dual Extruder |

Fast switching, material flexibility |

Slightly more hardware complexity |

Professional multi-material use |

|

Single Nozzle Switching |

Affordable, entry-level option |

Slower prints, more waste |

Hobbyists, budget workflows |

|

Tool-Changing |

Max flexibility, nozzle variety |

Complex setup, slower, costly |

Research, experimental setups |

|

Filament Mixing |

Color blending, visual effects |

Limited to compatible materials |

Visual prototypes, R&D |

You can use duplication mode to print two of the same model at once. Mirror mode lets you print a model and its mirror image together. These features help you save time and get more done.

Modern dual extrusion systems fix problems like oozing from the nozzle not in use. They use prime towers or ooze shields to clean the nozzle before switching. This keeps your prints looking neat.

Pros and Cons of Multiple Nozzles

Having more nozzles gives you more choices, but also more things to learn. Here are some things to think about:

- Multi-nozzle printers can print faster and use more materials.

- You can finish big projects quickly and add cool effects.

- You need to learn about calibration and fixing problems.

- Single nozzle printers are simple and easy to use.

- You spend less time setting up and cleaning with one nozzle.

|

Maintenance Challenge |

Description |

|---|---|

|

First Layer Adhesion |

The first layer might not stick well. You need to prep the surface and check the printer. |

|

Layer Shifting |

Layers can move if belts are loose or something blocks the printer. |

|

Stringing |

Filament can ooze during moves. You must change retraction or temperature settings. |

You should think about what is most important for your projects. If you want easy printing and less work, use a single nozzle. If you want speed, color, or more materials, try a multi-nozzle printer. You can start simple and upgrade as you learn more about 3D printing.

Nozzle Types and Sizes

Common Nozzle Sizes (0.2 mm, 0.4 mm, 0.6 mm, 1.0 mm)

You can choose from several nozzle sizes for your 3D printer. Each size works best for different jobs. The most popular size is 0.4 mm. This size gives you a good balance between speed and detail. If you want to print tiny objects with sharp details, you can use a smaller nozzle like 0.25 mm. For bigger projects, you might pick a larger nozzle, such as 0.6 mm or 1 mm. Larger nozzles print faster and make stronger parts, but you lose some detail.

Here is a table that shows the most common nozzle sizes and what they are best for:

|

Nozzle Size |

Typical Applications |

Advantages |

Disadvantages |

|---|---|---|---|

|

0.25 mm |

Text, jewelry, miniatures |

High resolution, fine details |

Slower print speed |

|

0.4 mm |

General purpose printing |

Balanced speed and quality |

N/A |

|

0.6 mm |

Flower pots, headphone stands |

Fast, durable prints |

Lower detail resolution |

|

1 mm |

Large objects, rapid prototyping |

Up to 5x faster printing |

Visible layer lines, less detail |

Nozzle Materials: Brass, Steel, and More

You can find nozzles made from different materials. The most common is brass. Brass nozzles work well with standard filaments like PLA, ABS, and PETG. They heat up quickly and cost less. If you use special filaments, like carbon fiber or glow-in-the-dark, brass nozzles wear out faster. Hardened steel or stainless steel nozzles last longer with abrasive filaments. Ruby-tipped nozzles are ultra-durable and handle any filament, but they cost more.

Here is a table that compares nozzle materials:

|

Nozzle Material |

Best For |

Advantages |

Limitations |

|---|---|---|---|

|

Brass (standard) |

PLA, ABS, PETG |

Affordable, great heat transfer |

Wears out quickly with abrasives |

|

Hardened Steel |

Carbon fiber, glass-filled |

Extremely wear-resistant, durable |

Lower heat transfer than brass |

|

Stainless Steel |

Food-safe, medical prints |

Corrosion-resistant, FDA-safe |

Not as tough with abrasives |

|

Ruby-Tipped |

Professional, long-term use |

Ultra-durable, premium precision |

Expensive |

- Brass nozzles wear out quickly with carbon fiber filaments.

- Hardened steel or stainless steel nozzles are better for abrasive materials.

- Hardened steel nozzles last much longer than brass, but they do not heat up as fast.

Note: Standard brass nozzles can last for months if you use regular filaments. If you print with abrasive filaments, you should switch to hardened steel or ruby-tipped nozzles for longer life.

Choosing the Right Size and Material

You need to match your nozzle size and material to your project. If you want fine details, pick a small nozzle. For strong, fast prints, use a larger nozzle. If you use regular filaments, brass nozzles work well and cost less. If you use abrasive filaments, choose hardened steel or ruby-tipped nozzles. Stainless steel nozzles are best for food-safe or medical prints.

Here are some steps to help you choose:

- Use 0.2–0.3 mm nozzles for high-resolution details.

- Stick with 0.4 mm for most general-purpose prints.

- Upgrade to 0.6–0.8 mm for strong, durable parts.

- Go 1.0 mm or bigger for large prototypes and fast printing.

- Pick brass for standard filaments and low cost.

- Choose hardened steel for abrasive filaments and long life.

- Select stainless steel for food-safe or medical projects.

- Try ruby-tipped nozzles for professional use and any filament.

You should also think about cost. Standard brass nozzles cost less, usually between $4 and $25. Specialty nozzles, like copper or ruby-tipped, can cost $15 to $50 or more. If you print a lot with abrasive filaments, the extra cost for a durable nozzle can save you money in the long run.

Tip: Always check your nozzle for wear if you use abrasive filaments. A worn nozzle can ruin your print quality and waste time.

You can get the best results from your 3D printer by choosing the right nozzle size and material for your project.

Nozzle Choice: Quality, Speed & Compatibility

Impact on Print Quality

Nozzle size and material change how your prints look. A smaller nozzle gives you sharp details and smooth surfaces. This is good for jewelry or tiny models. A bigger nozzle prints faster but makes rougher surfaces and less detail. The nozzle’s material matters too. Brass nozzles work best with regular filaments. Hardened steel nozzles last longer with tough filaments like carbon fiber. Here are some important things to remember:

- Small nozzles make fine details and high resolution.

- Big nozzles print faster but the surface is rougher.

- Flexible filaments work better with big nozzles. Rigid materials do well with small nozzles.

Print Speed and Strength

The nozzle’s diameter changes print speed and strength. Bigger nozzles let you print thick layers, so you wait less. Parts are stronger because thick layers stick together better. Check out this table:

|

Nozzle Diameter (mm) |

Fiber Alignment Effect |

|

|---|---|---|

|

10 |

Higher |

30 |

|

40 |

Lower |

N/A |

|

>20 |

Negligible |

N/A |

Keep your layer height between 25% and 80% of your nozzle size. For example, a 0.4 mm nozzle works well with a 0.2 mm layer height.

Filament Compatibility

Picking the right nozzle helps you use different filaments. Hardened steel nozzles are great for carbon fiber and glow-in-the-dark filaments. Brass nozzles work well with PLA and ABS, but wear out fast with rough filaments. Flexible filaments need bigger nozzles so they do not clog. Here is a quick guide:

|

Nozzle Type |

Filament Compatibility |

Key Features |

|---|---|---|

|

Hardened Steel |

Carbon fiber, glow-in-the-dark PLA |

High wear resistance |

|

Copper/Plated Brass |

PLA, ABS |

Fast warm-up, good heat transfer |

|

Brass |

PLA, ABS (not abrasives) |

High heat conductivity |

- Use hardened steel nozzles for rough filaments.

- Do not use brass nozzles for advanced filaments.

When you pick the right nozzle, your prints look better and you have fewer problems.

3D Printer Nozzle Care

Maintenance Tips

Taking care of your nozzle helps you get the best results from your 3D printer. Regular cleaning keeps prints smooth and prevents clogs. You should heat the nozzle before cleaning to melt any leftover plastic. This makes it easier to remove debris. Try using a cold pull to clear out deep-seated residue. A cold pull means you heat the nozzle, insert filament, let it cool, and then pull the filament out. This pulls out dirt and old plastic.

You can also use cleaning filament every few prints. It helps remove small bits that regular filament leaves behind. If you print often, check the nozzle for buildup or clogs. Clean the nozzle after long print sessions or when you see small clogs. Place a silicone sock over the heater block to keep the nozzle area cleaner. Avoid scraping the nozzle against the glass bed to prevent wear.

Tip: Set a schedule to inspect your nozzle. Regular checks help you spot problems early and avoid sudden breakdowns.

Store your filament in a dry place. Moisture in filament can cause clogs and poor print quality. If you use abrasive filaments, consider switching to a hardened steel nozzle for longer life.

When to Replace a Nozzle

Nozzles do not last forever. You should know when to replace them to keep your prints looking great. Look for these signs:

- The nozzle tip looks dull or shorter than before.

- You see marks or grooves inside the nozzle opening.

- The nozzle hole seems bigger than normal.

- Prints show under-extrusion or weak layer adhesion.

- You notice blobs or rough, uneven surfaces on your prints.

If you use brass nozzles, replace them every six months, or sooner if you use abrasive materials. Regular nozzle maintenance prevents clogs and keeps your printer running well. Clean and inspect your nozzle often to extend the life of your printer and improve print quality.

Picking the right nozzle for your 3D printer gives you better prints and less trouble. The size of the nozzle changes how much detail you get and how fast you print. The material of the nozzle decides how long it will last. You should test different nozzle sizes and materials to find what works best for your projects. Cleaning your nozzle often stops clogs and failed prints. If you watch these things, your prints look better and 3D printing is easier.

FAQ

How often should you clean your 3D printer nozzle?

You should clean your nozzle after every few prints. If you notice clogs or poor print quality, clean it right away. Regular cleaning helps you avoid bigger problems and keeps your prints looking sharp.

Can you use any filament with any nozzle?

No, you cannot use every filament with every nozzle. Abrasive filaments, like carbon fiber, need hardened steel or ruby-tipped nozzles. Standard brass nozzles work best with PLA, ABS, and PETG.

What happens if your nozzle size is too small for your project?

A nozzle that is too small can clog easily and slow down your print. You might see weak parts or missing details. For large or strong prints, use a bigger nozzle.